The global stainless steel seamless tube market is entering a phase of steady, diversified, and value-driven expansion. As industries demand higher performance under increasingly harsh conditions, seamless tubes are gaining preference over welded ones—especially in heat exchanger, petrochemical, power, and clean energy applications.

According to recent market reports, the stainless steel seamless tube market is projected to grow from USD 3.88 billion in 2025 to over USD 5.15 billion by 2030, reflecting a CAGR of approximately 5.8%.

In this article, we examine the growth drivers, regional dynamics, and key opportunities that define the market outlook—and how DLSS Pipeline is positioned to serve this global transformation.

1. What’s Driving Global Growth?

A. Infrastructure Modernization

Global investment in power plants, chemical plants, district heating, and renewable energy systems is increasing the demand for high-performance piping.

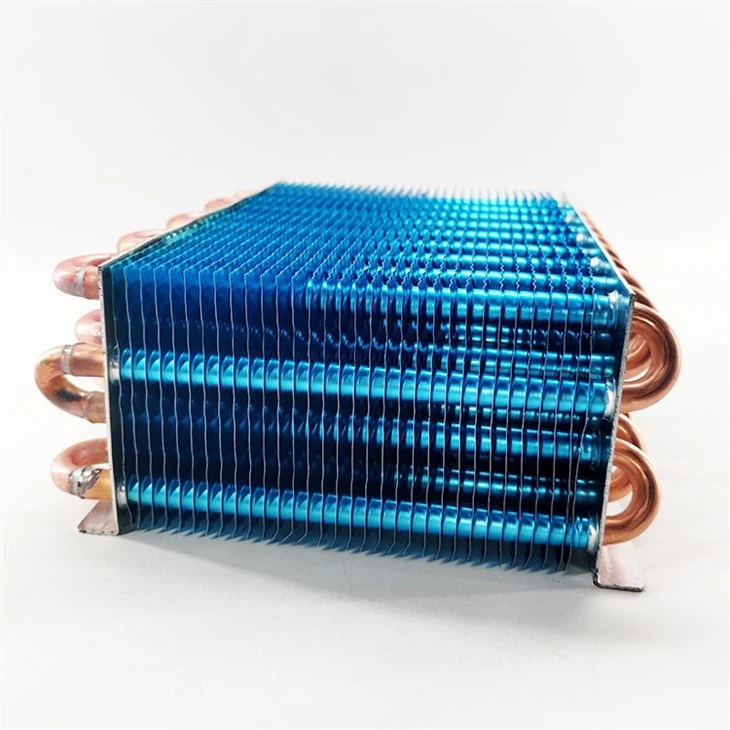

B. Rise in Heat Exchanger Applications

Shell-and-tube and U-bend heat exchangers are widely adopted in energy, HVAC, and food processing—driving steady tube consumption.

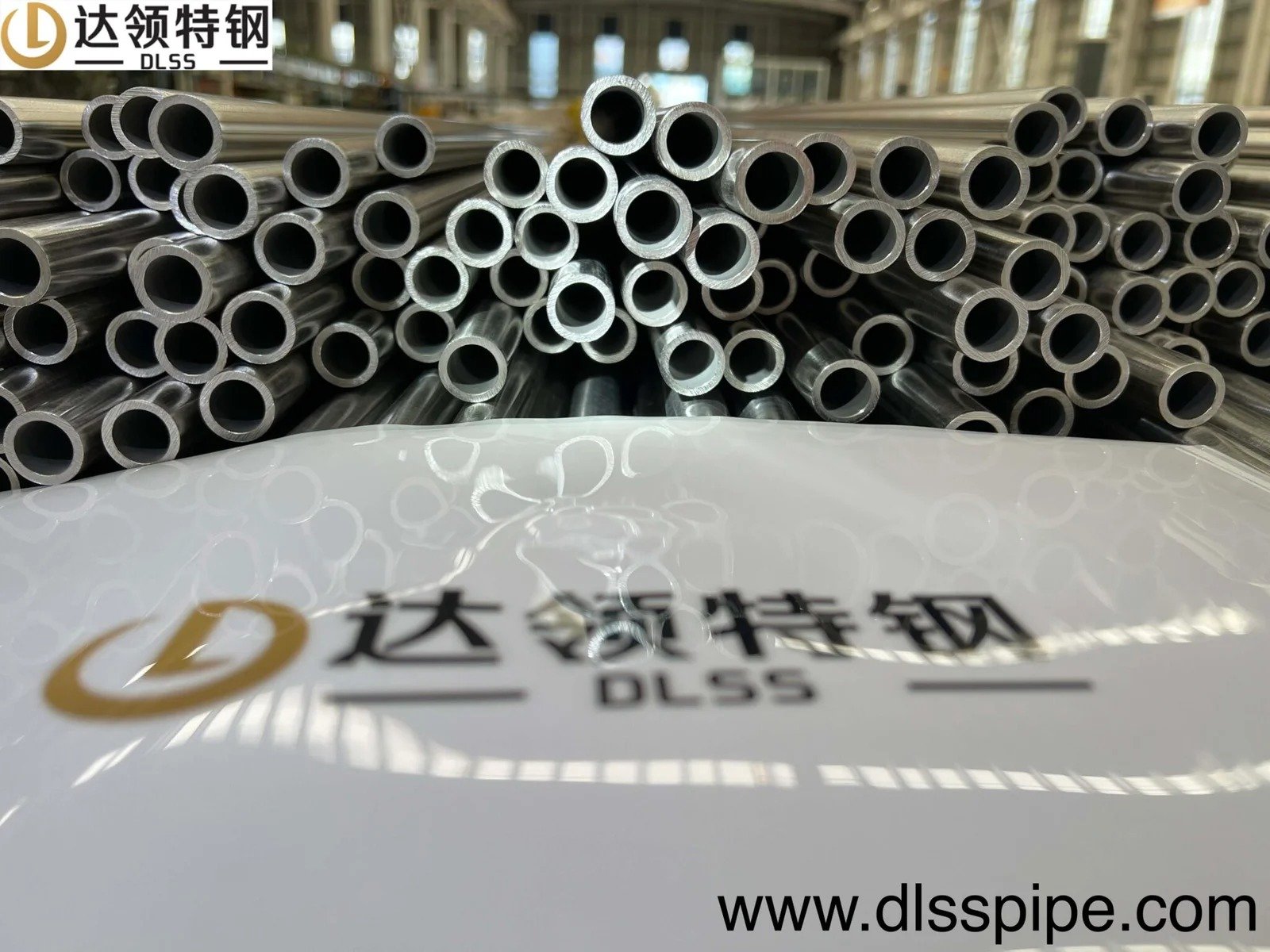

C. Preference for Seamless over Welded

Seamless tubes offer better pressure resistance, dimensional accuracy, and uniformity—making them the go-to choice for demanding environments.

D. Industrial Upgrades in Developing Regions

Asia-Pacific, the Middle East, and parts of Africa are rapidly upgrading refineries, steel plants, and wastewater systems—fuelling demand for seamless pipes.

2. Market Size and Forecast (2025–2030)

- 2025: USD 3.88 billion

- 2030: USD 5.15 billion

- CAGR: ~5.8%

- Heat exchanger tube segment CAGR: ~9.5% (2025–2032)

This growth is supported by energy efficiency regulations, urbanization, and a growing shift toward cleaner process technology—all of which rely on seamless piping solutions.

3. Regional Highlights

Asia-Pacific (APAC)

- Largest and fastest-growing market (>40% share)

- Strong demand in China, India, Vietnam, and Indonesia

- Government push for industrial and energy self-sufficiency

North America

- Mature market driven by shale gas, retrofitting, and sustainability mandates

- Strong preference for ASME SA213-compliant tubes

Europe & Middle East

- Focused on high-alloy materials, duplex/super duplex grades

- Energy transition (hydrogen, solar thermal, offshore wind) spurring growth

4. What This Means for Engineers and Buyers

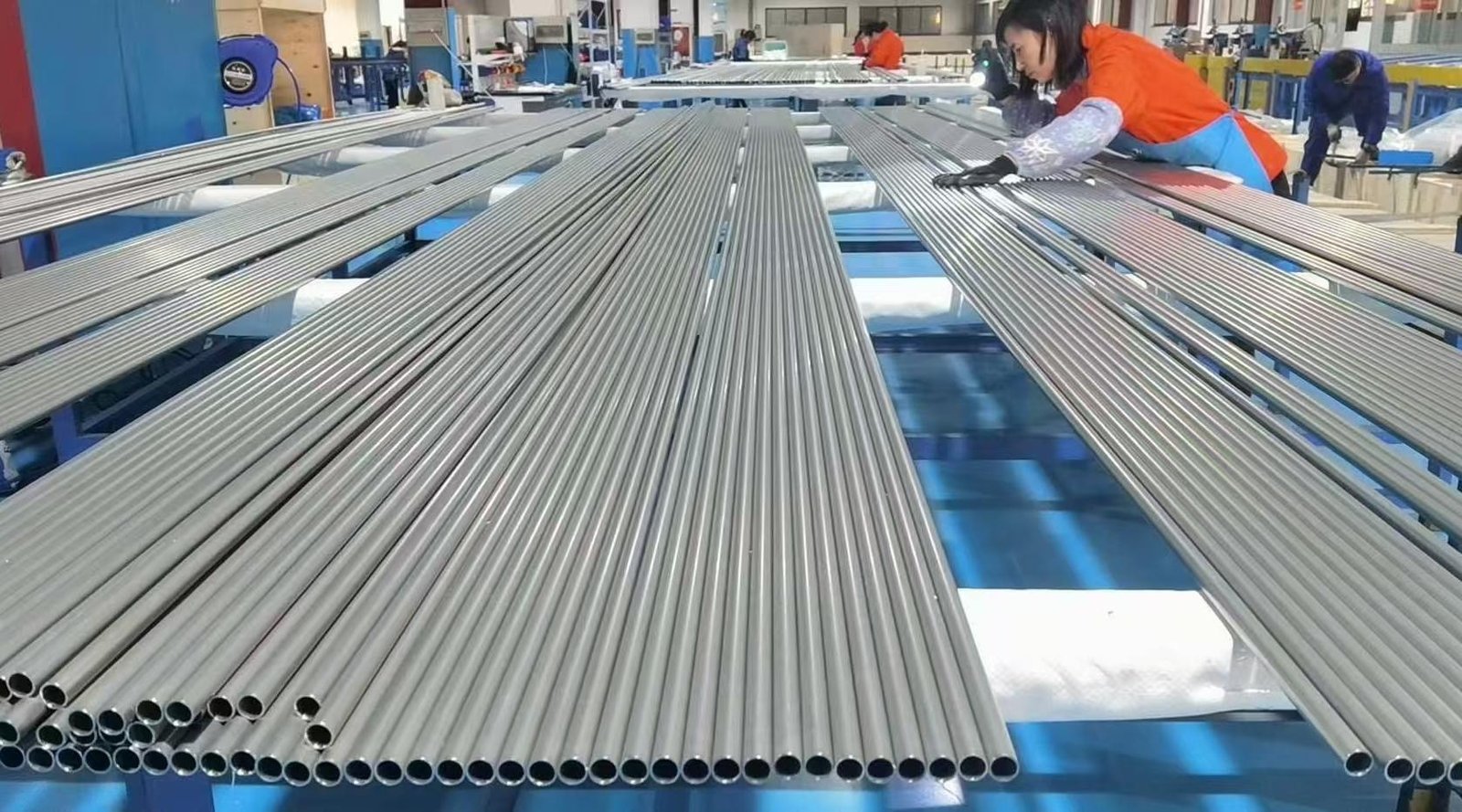

- Supply security: Choosing capable manufacturers with integrated production and QC matters more than ever

- Standard versatility: Projects require EN, ASME, and sometimes dual-certified tubing

- Tailored solutions: Custom lengths, heat treatment, and surface finish (pickled/BA) are increasingly demanded

DLSS Pipeline provides seamless stainless steel tubes with full compliance to ASME SA213, EN 10216-5, and PED directives—exported to 40+ countries worldwide.

Frequently Asked Questions (FAQ)

Q1: Why is the market shifting toward seamless tubes?

Seamless tubes offer superior strength, resistance to pressure and corrosion, and are more reliable for high-temperature or aggressive media.

Q2: Which industries will drive the most growth by 2030?

Heat exchangers in power, HVAC, petrochemical, food, hydrogen, and marine systems.

Q3: What grades are leading this growth?

TP316L, TP317L, 2205 duplex, and S32750 super duplex are in high demand for their corrosion resistance.

Conclusion

The stainless steel seamless tube market is on a sustainable upward trajectory, powered by global industrial growth, energy transition, and quality-conscious engineering. For manufacturers, EPCs, and system designers, aligning with reliable tube suppliers is key to project success.

DLSS Pipeline is ready to support your next high-performance application with precision-manufactured, inspection-ready seamless tubes.