With wind power accounting for over 25% of electricity in key global markets, operators are facing a new challenge: maintaining, upgrading, and replacing aging cooling and heat transfer systems, especially in offshore environments.

As a result, demand for stainless steel finned tubes—used in turbine cooling, nacelle HVAC, and heat exchangers—is rapidly rising. For precision tube manufacturers, this represents a fast-emerging growth segment.

1. Why Wind Farms Are Upgrading Their Cooling Systems

Wind turbines, particularly offshore platforms, are exposed to:

- Salt-laden air, which accelerates corrosion

- Thermal cycling and vibration, which degrades conventional aluminum fins

- Long maintenance intervals, requiring durable materials that last 20+ years

- Higher output designs, which generate more heat and require efficient dissipation

According to IRENA, over 300 GW of global wind capacity is older than 10 years—creating a sizable retrofit market for finned tube upgrades.

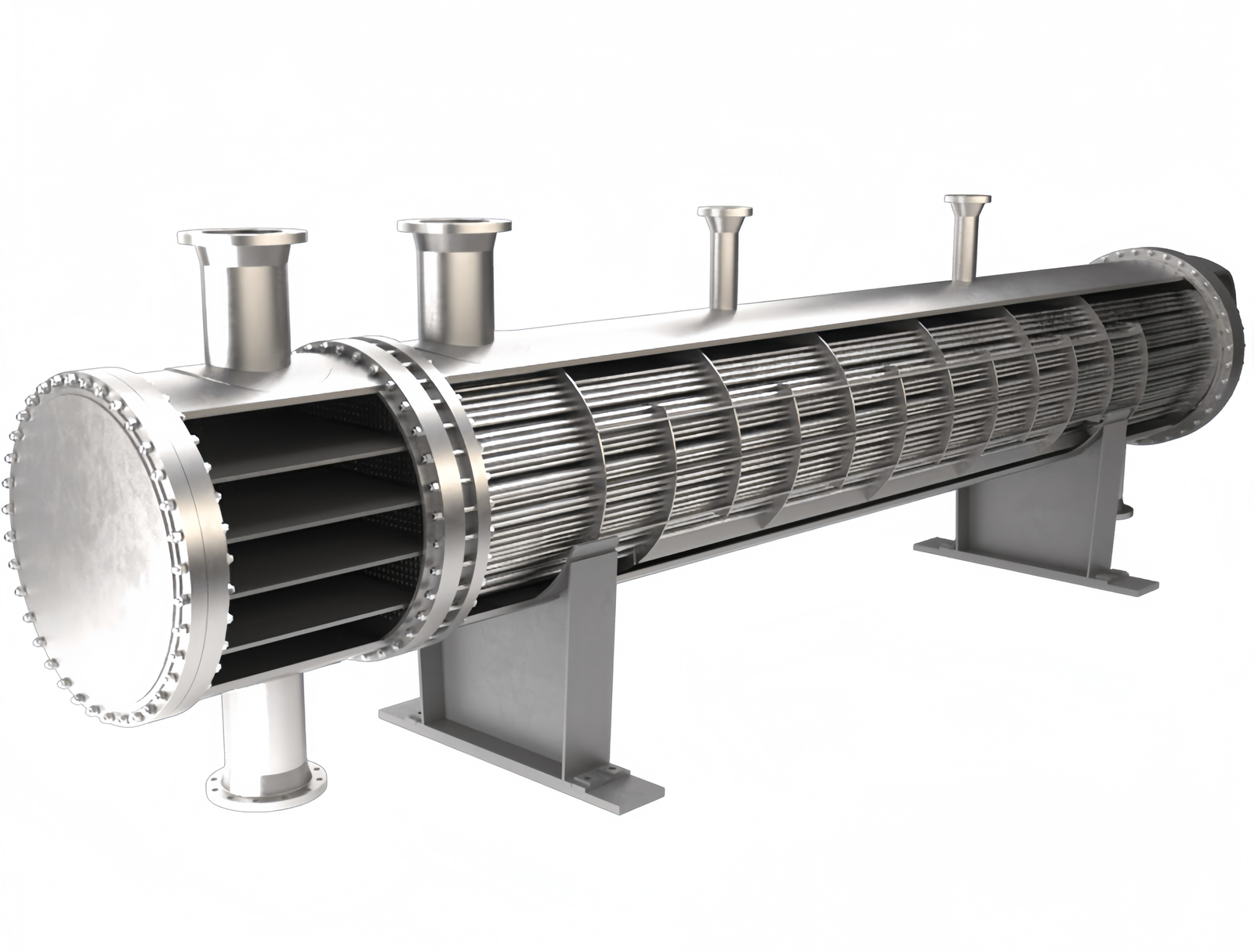

2. Where Finned Tubes Are Used in Wind Turbines

| Application | Role of Finned Tube |

|---|---|

| Turbine oil cooling systems | Dissipates heat from hydraulic and gear oil systems |

| Nacelle HVAC | Controls temperature for sensitive electronics and generators |

| Transformer and brake cooling | Removes heat in high-friction, high-load areas |

| Hydrogen-cooled generators (next-gen) | Heat transfer under pressurized systems |

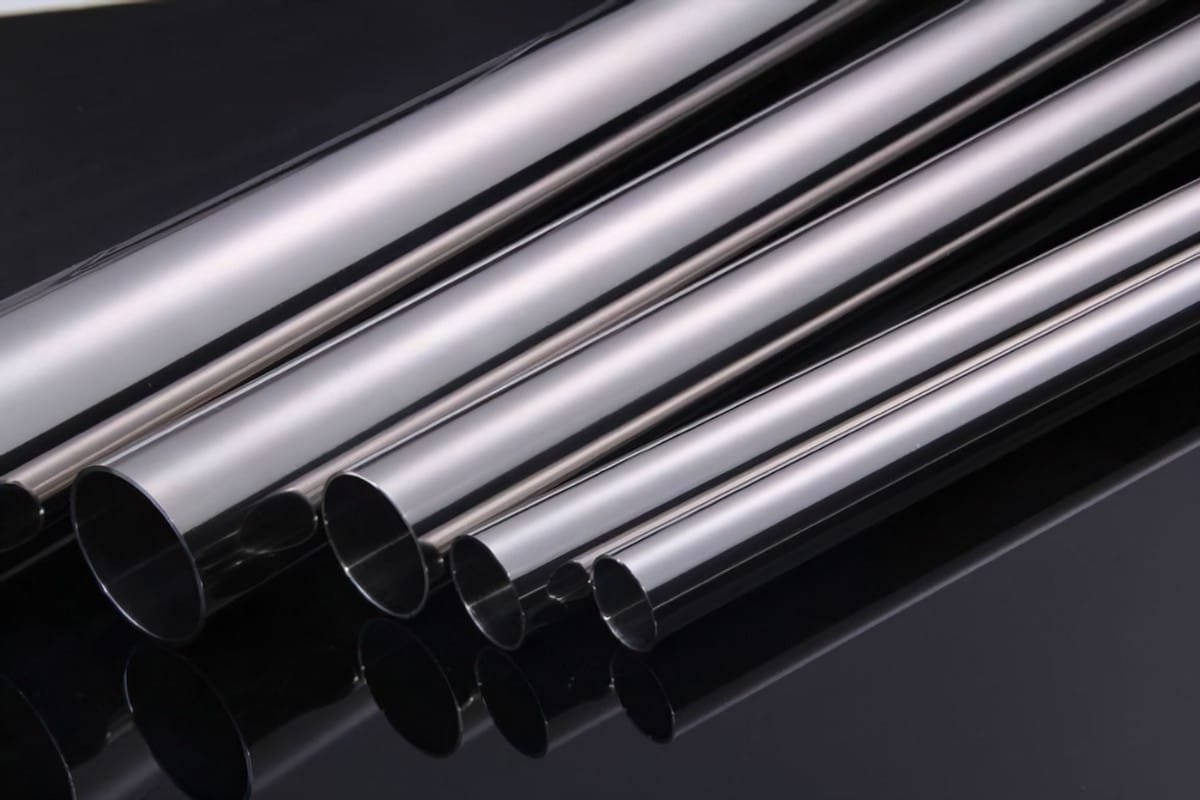

3. Why Stainless Steel Is Replacing Carbon Steel or Aluminum

Traditional finned tubes made of carbon steel or aluminum struggle to meet offshore durability needs. Stainless steel offers:

- Corrosion resistance (especially in chloride-rich offshore air)

- Higher thermal fatigue resistance

- Welded or integrally extruded fin construction for vibration strength

- Low maintenance lifecycle costs

Grades such as TP304L, TP316L, and S31803 duplex are being increasingly specified in tenders.

4. Who Is Buying: Key Markets and Players

| Region | Trend | Opportunity |

|---|---|---|

| North Sea (UK, Germany, Denmark) | Retrofit of old farms, nacelle upgrades | PED + ASME-certified fin tubes |

| China & Taiwan offshore zones | Large-scale new farm construction | High-volume, corrosion-resistant tubing |

| US East Coast (New Jersey, Virginia) | New floating wind projects | Lightweight stainless fin coils |

| Brazil & South Africa | Hybrid power plants with wind + hydrogen | Tubes for turbine + electrolyzer cooling |

OEMs and EPC contractors increasingly require third-party inspection, dimensional precision, and full documentation (EN 10204 3.1).

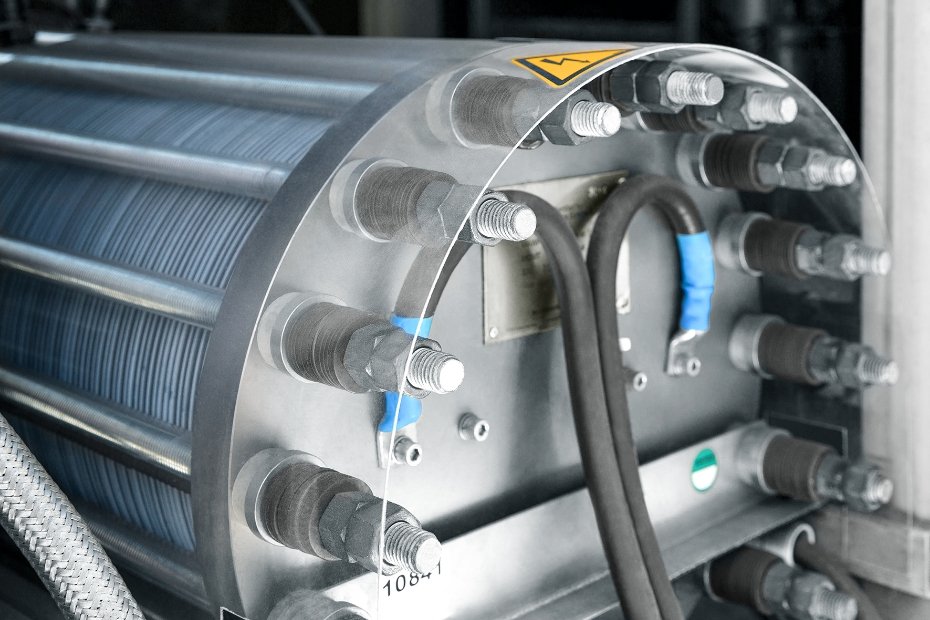

5. How Tube Manufacturers Can Seize the Market

To succeed in this space, stainless steel tube suppliers must:

- Offer custom finned tube solutions (welded vs extruded fins, U-bent bundles)

- Provide material recommendations for offshore durability

- Support pre-assembly or packaging by bundle to reduce installation time

- Be ready for PED/ASME compliance audits

- Demonstrate experience in low-volume, high-spec orders

DLSS, for instance, is equipped to deliver finned tubes with 100% eddy current testing, cut-to-length, and seaworthy export packing for renewable energy customers worldwide.

Frequently Asked Questions (FAQ)

Q1: What’s the difference between welded and extruded finned tubes?

A: Welded fins are wrapped and TIG welded around the base tube—better for high-temp applications. Extruded fins are mechanically forced from a sleeve—excellent for corrosion and mechanical strength.

Q2: Can stainless steel fins compete with aluminum on thermal conductivity?

A: While aluminum has higher conductivity, stainless offers greater mechanical strength, durability, and resistance to fin erosion, which is crucial offshore.

Q3: What standards apply for wind turbine heat exchanger tubes?

A: ASME SA213, ASTM A249/A269, and EN10216-5, depending on location and customer. PED and CE marking may be required in EU projects.

Q4: Do wind farm operators require carbon footprint data?

A: Increasingly yes—especially in Europe. Suppliers offering ISO 14067 or EPD-certified tubes gain a competitive advantage.

Conclusion: Wind Power Needs More Than Blades—It Needs Smart Tubes

As wind farms expand and age, the cooling infrastructure inside turbines becomes a critical point of failure or efficiency gain. Finned tubes may be a small component—but they carry big impact.

For stainless steel tube suppliers who can offer corrosion-resistant, precision-engineered, and long-life solutions, the wind sector is a growth frontier worth watching.

And delivering high-performance tubes? That’s the kind of tailwind every customer needs.