The stainless steel seamless tube industry is undergoing a quiet but profound transformation—not just driven by technical demands, but by Environmental, Social, and Governance (ESG) goals and the global energy transition.

As governments, investors, and end-users demand cleaner, longer-lasting, and traceable materials, tube manufacturers are under growing pressure to reduce carbon footprint, improve transparency, and supply materials suited for clean energy systems.

In this article, we explore how ESG and the green energy boom are influencing stainless steel seamless tube production, sourcing, and applications—and how DLSS Pipeline is evolving to meet this challenge.

1. ESG Is Now a Procurement Requirement

Large EPCs and multinational corporations are integrating ESG into procurement policies. This includes:

- Preference for low-emission stainless steel production

- Traceability of raw materials and ethical sourcing

- Compliance with RoHS, REACH, and local green building codes

- Transparent supply chain reporting and audits

Tube suppliers must now show they’re part of the low-carbon solution—not the problem.

2. Green Energy Projects Drive Tube Innovation

A. Hydrogen Systems

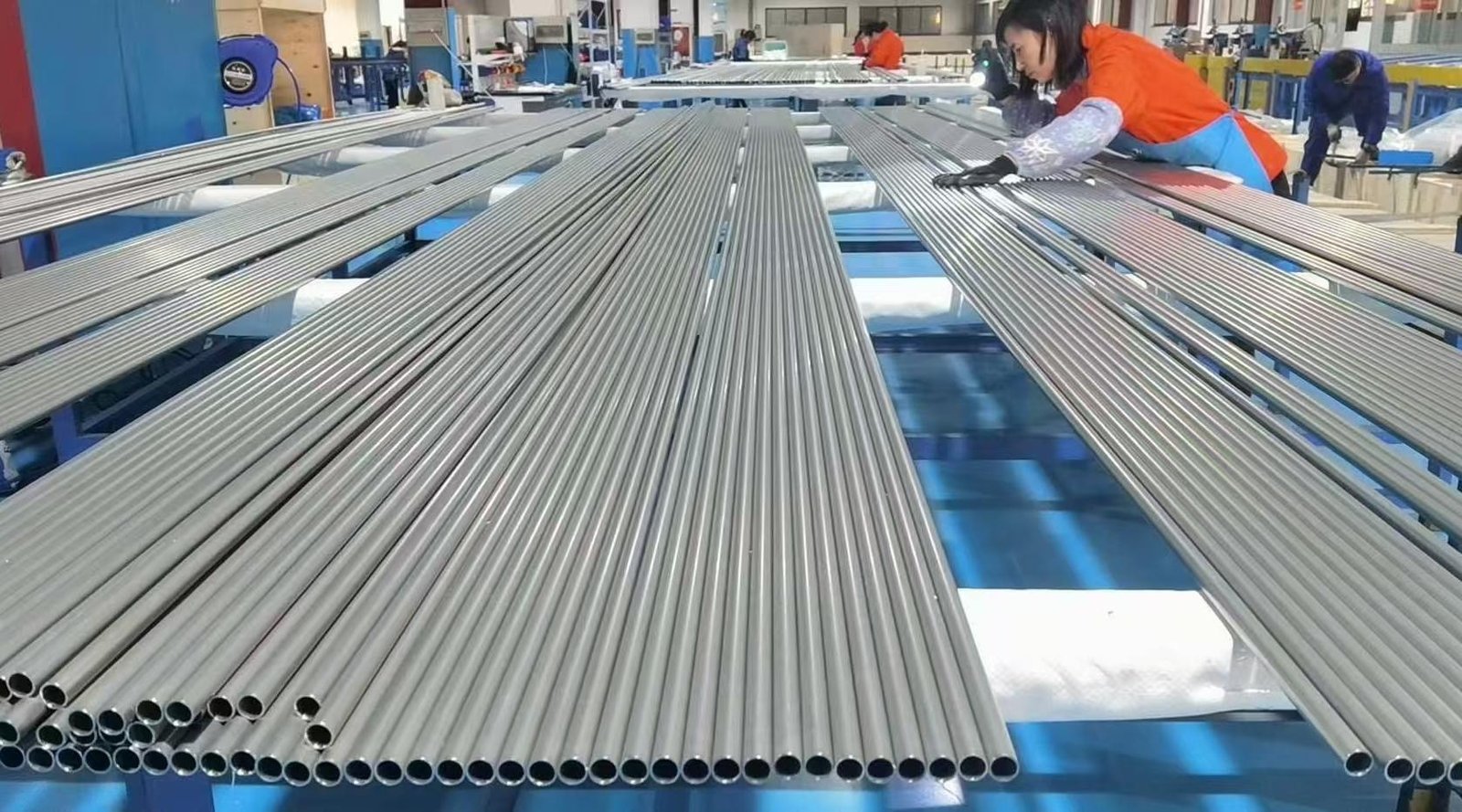

- Require high-purity stainless steel tubes with minimal contaminants

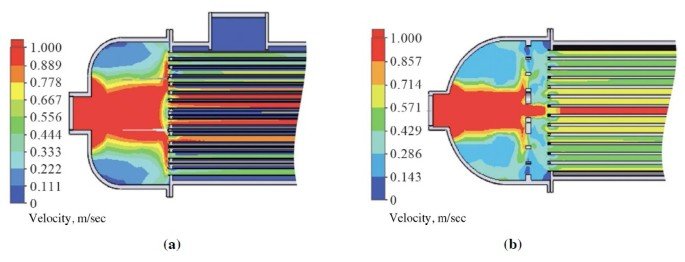

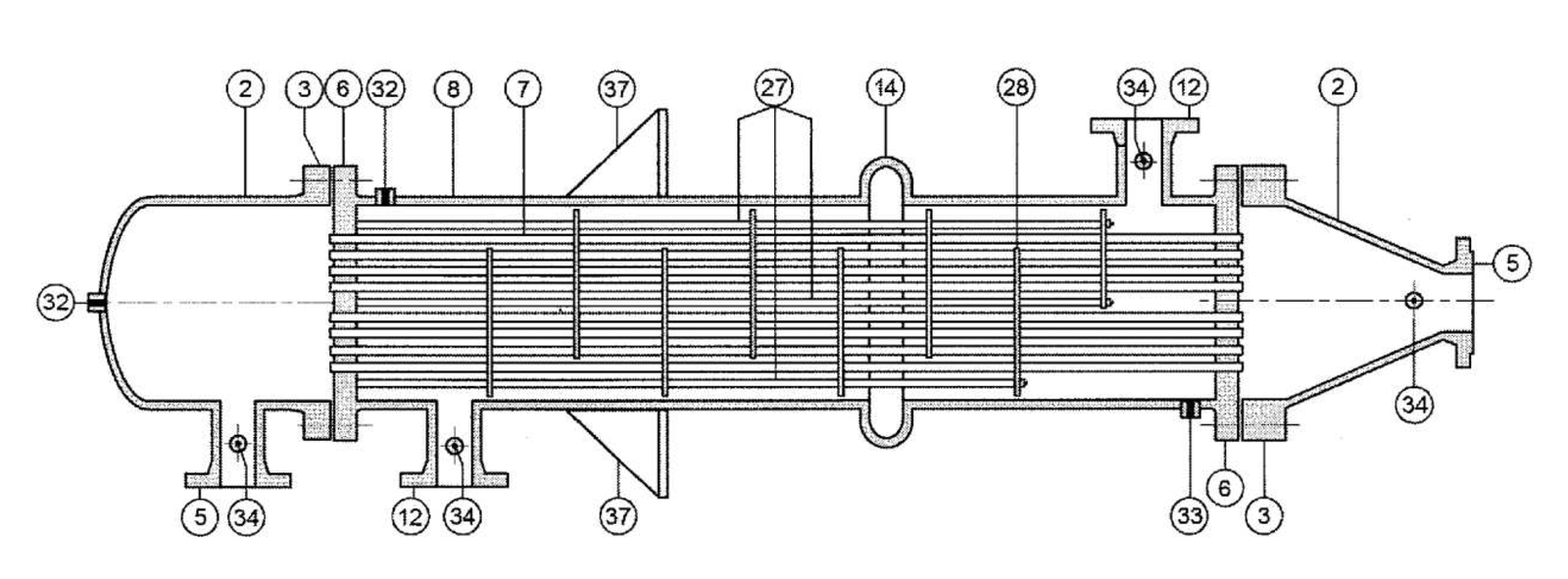

- Seamless tubes used in electrolyzers, compressors, and heat recovery

- Grades: 316L, 904L, 2205 (for pressure and corrosion resistance)

B. Geothermal Plants

- Demanding on corrosion and pressure; 2205, 2507, and titanium tubes used

- U-bent seamless tubes required in geothermal preheaters

C. Solar Thermal & Biomass

- Heat exchangers in CSP and bio-reactors require bright annealed or pickled tubes

- Smooth ID, long service life, and weldability are critical

DLSS supports all these applications with project-grade, certified seamless stainless tubes. Visit www.dlsspipeline.com

3. What Makes a Stainless Tube “Sustainable”?

| Aspect | Description |

|---|---|

| Long service life | Minimizes maintenance and material replacement waste |

| Recyclability | Stainless steel is 100% recyclable at end-of-life |

| Low carbon content | Control of C, N, and inclusion content during steelmaking |

| Certified quality | Reduces failure risk, ensuring system-level energy savings |

| Sustainable packaging | DLSS uses ISPM-15 crates, anti-corrosion oil, and labeling |

4. DLSS Commitment to Sustainable Solutions

- Energy-efficient annealing furnaces to reduce gas and electricity use

- Closed-loop pickling systems to minimize wastewater and chemical discharge

- Smart logistics planning to reduce transport emissions

- Material traceability per EN 10204 3.1 and 3.2

- Support for green project documentation and sustainability declarations

DLSS works closely with EPCs, consultants, and end users to align with sustainability targets.

Frequently Asked Questions (FAQ)

Q1: Is stainless steel really a “green material”?

Yes. With a long lifecycle, high strength-to-weight ratio, and full recyclability, stainless steel supports long-term sustainability goals.

Q2: Can seamless tubes be certified for ESG-related tenders?

DLSS supports ESG reporting, traceability, and compliance with European, American, and Gulf region environmental specs.

Q3: What green energy sectors use seamless tubes the most?

Hydrogen, geothermal, solar thermal, waste-to-energy, and heat recovery systems in green buildings.

Conclusion

Sustainability is no longer optional—it’s an industry standard. For stainless steel seamless tube producers, the challenge is to deliver performance and accountability.

At DLSS Pipeline, we are investing in cleaner manufacturing, smarter inspection, and material certification systems that help clients meet both technical and environmental targets.

Partner with us to build your next-generation green energy system.