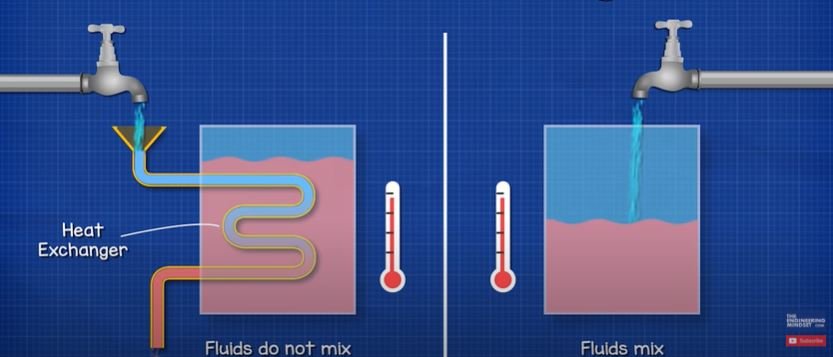

The global heat exchanger market is heating up—literally and economically. With rising demand for energy efficiency, industrial process optimization, and sustainable thermal management, stainless steel heat exchanger tubes are becoming a critical infrastructure material across multiple industries.

Recent industry research forecasts a compound annual growth rate (CAGR) of 9.5% through 2032 for the heat exchanger tube segment alone. That translates to billions in new project value—and a global push for high-performance, corrosion-resistant stainless steel tubing.

In this article, we explore what’s driving this surge, where the opportunities lie, and how DLSS Pipeline is helping engineers and procurement teams stay ahead of the curve.

1. Why Is Heat Exchanger Tube Demand Accelerating?

A. Energy Transition Projects

Clean energy sectors (hydrogen, solar thermal, biomass, geothermal) require large-scale heat recovery, cooling, and preheating—driving demand for U-tubes, duplex tubes, and BA/AP-finished coils.

B. Industrial Efficiency Regulations

Global initiatives to reduce carbon emissions and boost energy efficiency (like ISO 50001, EU Energy Directive) push industries to install or upgrade heat exchangers with high-efficiency tubes.

C. Growth in Power Generation

New power plants (including combined cycle, nuclear, and waste-to-energy) are driving tube demand for condensers, preheaters, and superheaters.

D. Booming HVAC and District Heating

Urbanization and climate control investment—especially in Asia and Eastern Europe—are expanding HVAC tube consumption in stainless steel materials.

2. Key Sectors Driving Growth

| Industry | Tube Application | Growth Factors |

|---|---|---|

| Petrochemicals | Heat recovery, reboilers, condensers | Expansion of refining and chemical production |

| Power Generation | Feedwater heaters, preheaters, condensers | Retrofitting and new projects worldwide |

| Food & Beverage | Pasteurizers, CIP systems, heating coils | Demand for clean, corrosion-resistant tubing |

| Pharmaceutical | Clean steam generators, purified water systems | GMP compliance, ultra-low surface roughness (BA) |

| Renewable Energy | Solar thermal loops, biomass heating exchangers | Government incentives and ESG funding |

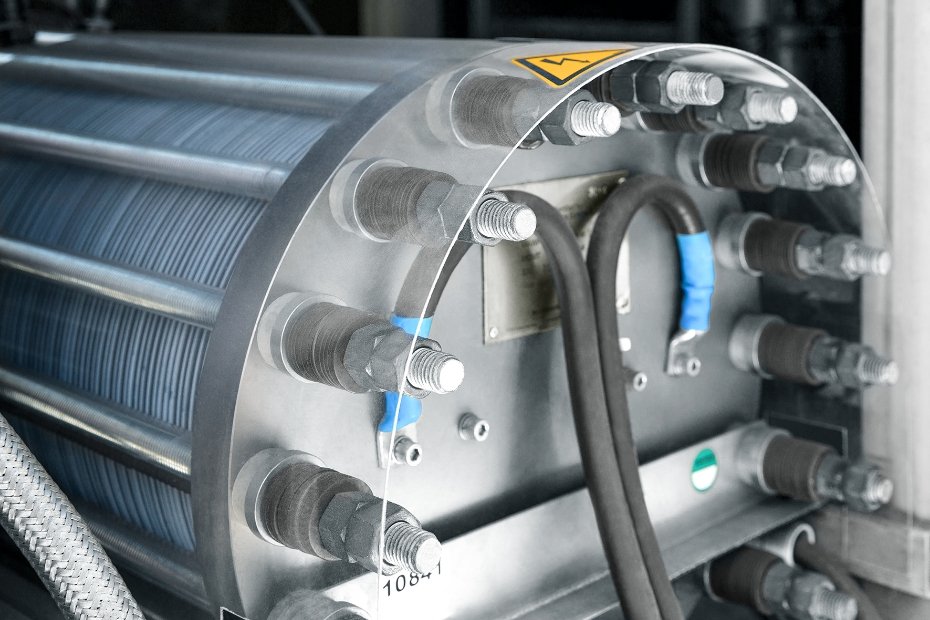

3. Technical Preferences Shaping the Market

- Material grades in high demand: TP316L, TP317L, 904L, 2205, S32750

- Preferred finishes: Bright annealed (BA) for hygiene, pickled (AP) for chemical duty

- Form factor trends: U-bent, straight cut-to-length, multi-pass coils

- Dimensional preferences: OD 12.7–38.1 mm, wall thickness 0.8–3.0 mm, tolerance class as per ASME or EN standards

4. Regional Outlook: Where Is Growth Happening?

- Asia-Pacific: Leading demand, especially in China, India, and Southeast Asia for power, HVAC, and industrial chemical plants

- Europe: Strong demand in clean energy and sustainable HVAC retrofit projects

- Middle East & Africa: Refinery and water desalination driving duplex/super duplex tube needs

- North America: Stable growth in process upgrades and regulatory replacement cycles

DLSS supplies precision stainless steel tubes to EPCs and OEMs across all these regions. Learn more: www.dlsspipeline.com

Frequently Asked Questions (FAQ)

Q1: Why is CAGR for heat exchanger tubes so high compared to the general tube market?

Because of combined growth from diverse sectors—energy, food, pharma, and infrastructure—all converging around better thermal control.

Q2: What’s the most demanded tube configuration?

U-bent seamless stainless steel tubes with post-bend stress relief and customized leg lengths, packed in seaworthy wooden crates.

Q3: What makes DLSS a reliable heat exchanger tube partner?

In-house manufacturing, full traceability (EN 10204 3.1/3.2), support for ASME/EN/JIS standards, and experience in 40+ export markets.

Conclusion

The heat exchanger tube market is experiencing a structural boom—driven by efficiency mandates, clean energy, and industrial process upgrades. Engineers, EPCs, and tube buyers must act now to secure high-quality, globally compliant tube supply.

DLSS Pipeline is your trusted partner for stainless steel tube solutions built for the demands of the next decade.