High-frequency welded finned tubes are one of the most widely used designs in industrial heat exchangers due to their strong metallurgical bonding and excellent heat transfer capabilities. This manufacturing method ensures a durable, efficient, and long-lasting solution for demanding thermal applications.

If you are unfamiliar with finned tubes in general, read our guide on What is a Finned Tube and How It Improves Heat Exchanger Efficiency. For a complete overview of finned tube types, see Different Types of Finned Tubes and Their Applications.

How High-Frequency Welded Finned Tubes Are Made

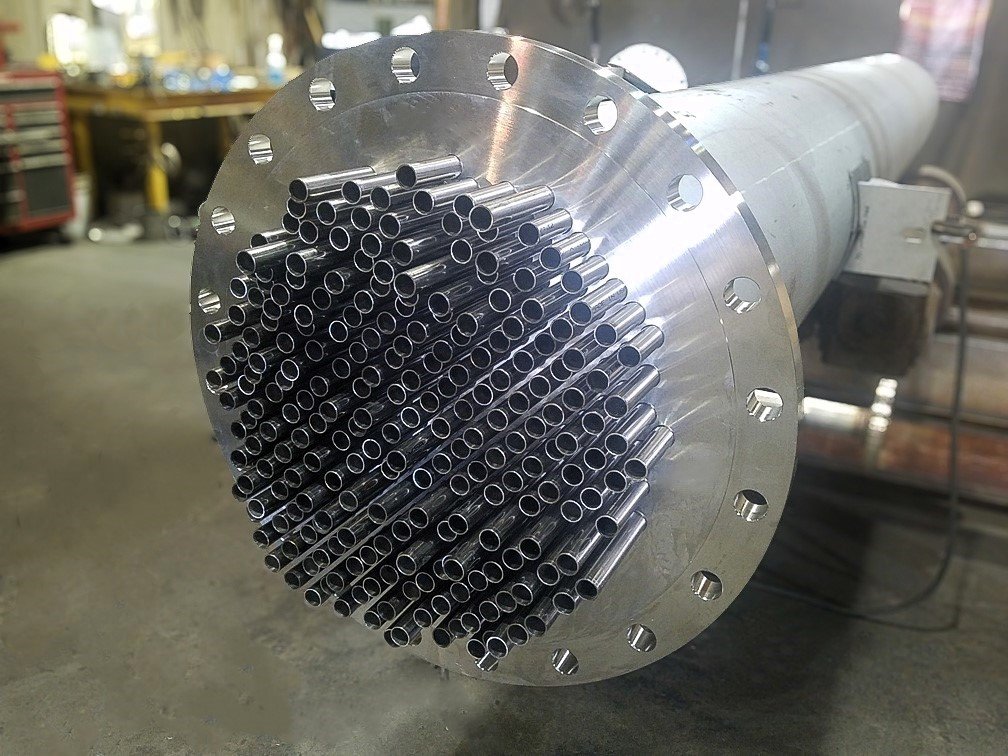

The manufacturing process involves helically winding a strip of steel or alloy fin material around the base tube, then welding the fin to the tube using high-frequency electrical current. This method creates:

- A metallurgical bond between the fin and the tube wall

- Minimal thermal resistance at the fin-tube interface

- High mechanical strength and vibration resistance

Key Advantages

- Excellent Heat Transfer Efficiency – Strong weld ensures effective thermal conduction from fin to tube.

- High Durability – Resistant to fin loosening under high thermal stress or vibration.

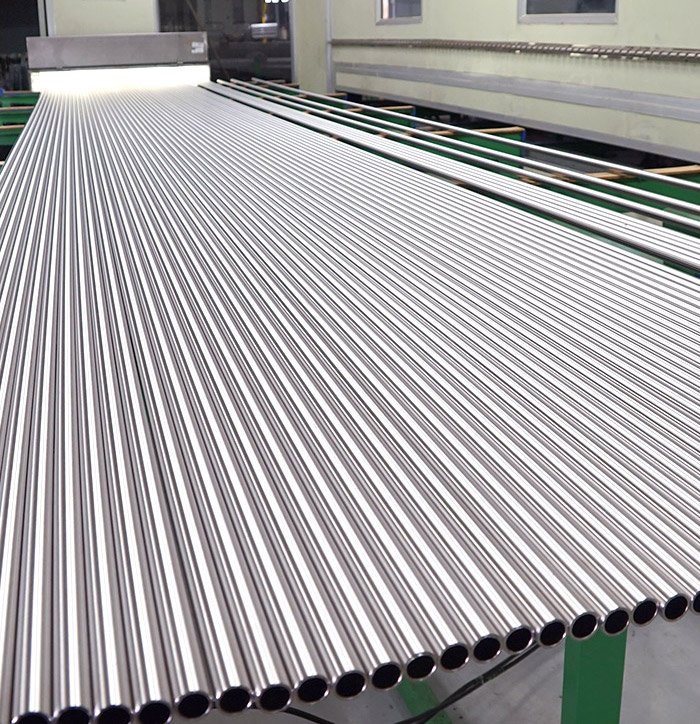

- Wide Material Options – Carbon steel, stainless steel, alloy steel, and other special alloys can be used.

- Cost-Effective for Long-Term Use – Extended service life reduces maintenance frequency.

- Adaptable Design – Suitable for custom fin pitch, height, and thickness.

Ideal Applications

High-frequency welded finned tubes are commonly used in:

- Boilers & Economizers – For waste heat recovery in power plants.

- Air-Cooled Heat Exchangers – Particularly in petrochemical and oil & gas plants.

- Gas Heaters & Coolers – Where high temperature resistance is needed.

- Industrial Dryers – For heating air in process industries.

Maintenance Considerations

Although welded finned tubes are durable, performance can still degrade over time due to fouling. To maintain peak efficiency:

- Implement a regular Heat Exchanger Maintenance Checklist

- Use cleaning methods suitable for the tube and fin material

- Monitor temperature differences to detect fouling early

Conclusion

High-frequency welded finned tubes are a proven choice for industries that demand both performance and durability. Their robust construction ensures reliable heat transfer even in the most challenging environments.

DLSS offers precision manufacturing of high-frequency welded finned tubes, with customizable designs to meet specific project needs.

Contact us today via www.dlsspipeline.com or email info@dlsspipe.com for expert advice and a tailored quotation.