Meta Description:

How durable are stainless steel seamless pipes? Learn about average service life, key factors that affect corrosion and fatigue, and how to extend performance in industrial systems.

Introduction

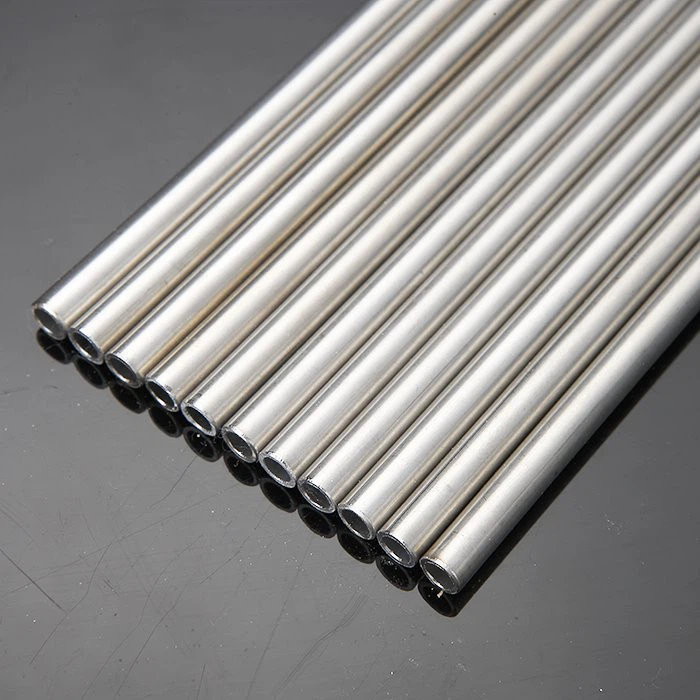

Stainless steel seamless pipes are widely known for their long service life, but just how long can they last?

Under ideal conditions, seamless stainless steel pipes can last 50 years or more. However, actual lifespan depends on factors such as:

- Material grade

- Environment (humidity, salinity, pH)

- Pressure and temperature

- Installation and maintenance quality

In this article, we explore realistic service life expectations, factors that reduce longevity, and tips to maximize the performance of your piping system.

Typical Lifespan of Stainless Steel Pipes

| Environment | Expected Lifespan | Notes |

|---|---|---|

| Indoor water systems | 50+ years | Minimal corrosion, low stress |

| Chemical plants with acids | 10–25 years | Depends on grade (e.g., TP316L, Incoloy 825) |

| Seawater or coastal environments | 10–20 years | Risk of pitting unless Duplex/Super Duplex |

| Boiler/steam lines | 20–40 years | Needs regular pressure testing and control |

| Food & pharma applications | 30–50 years | With pickled or EP surfaces |

Source: Nickel Institute – Corrosion Data

What Factors Affect Pipe Longevity?

1. Material Grade

TP304 lasts well in clean water but corrodes in salty or acidic media. Use TP316L, Duplex, or Incoloy in harsh environments.

2. Corrosive Exposure

High chloride, low pH, or stagnant flow can trigger corrosion and reduce service life. Avoid crevices and use smooth ID pipes in such cases.

3. Operating Temperature & Pressure

Thermal cycling or excessive pressure causes fatigue and microcracks. Refer to ASME B31.3 piping rules.

4. Welding & Fabrication

Improper welding may cause sensitization or reduce corrosion resistance. Use qualified WPS and post-weld treatments.

5. Maintenance Practices

Systems that are cleaned, flushed, and inspected regularly can exceed expected lifespan by decades.

How to Maximize Service Life

- Select the correct stainless grade for the medium

- Use pickled or electropolished finish for corrosive or sanitary applications

- Avoid stagnant flow and oxygen-deprived zones

- Store pipes with end caps and in dry, ventilated spaces

- Conduct periodic NDT inspections (UT, PT, EC)

More info: ASTM A213 & A269 Seamless Pipe Standards

Frequently Asked Questions (FAQ)

Q1: Can stainless pipes last over 50 years?

Yes, in clean, low-corrosion environments. TP316L or better grades are key to long service life.

Q2: What shortens the lifespan of stainless pipes?

Corrosive chemicals, chloride attack, mechanical stress, and poor installation practices.

Q3: Does wall thickness affect pipe life?

Yes. Thicker walls can delay perforation due to corrosion, especially in aggressive conditions.

Q4: How do I confirm expected pipe life for a project?

Consult NACE MR0175 for sour service, and work with suppliers like DLSS who provide grade-specific technical advice.

Conclusion

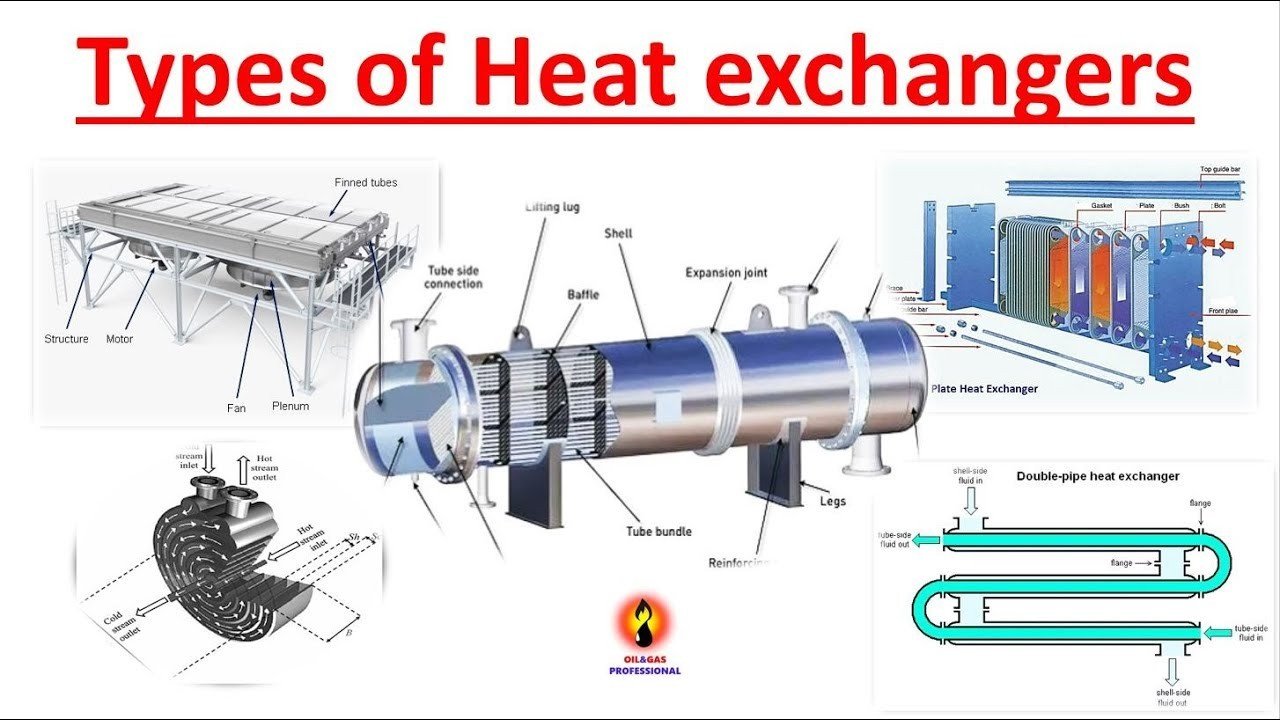

Stainless steel seamless pipes offer decades of durability when selected, installed, and maintained correctly.

From heat exchangers to sanitary systems, proper grade and surface treatment can extend service life and reduce lifetime costs.

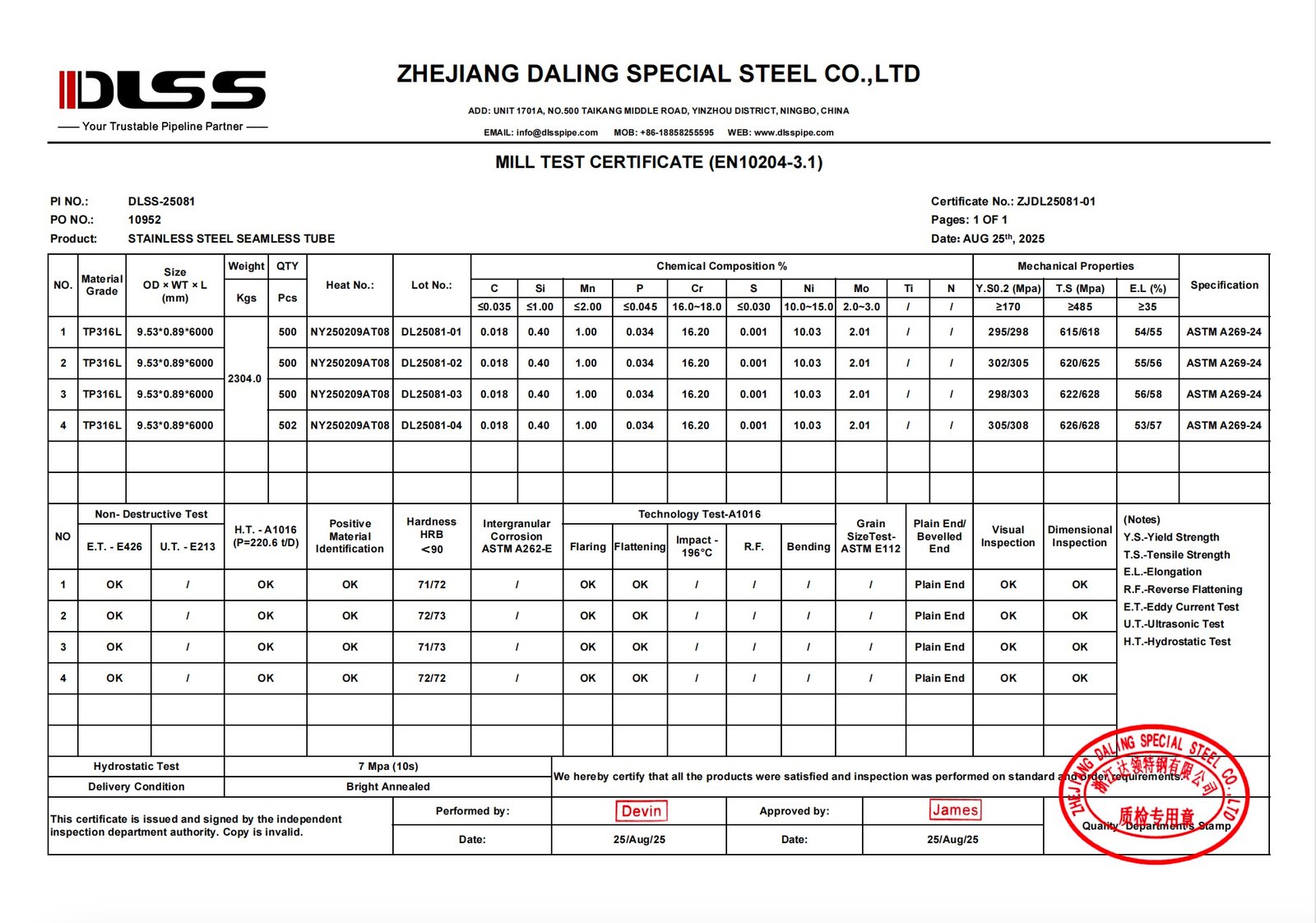

DLSS helps clients worldwide select the best pipe solutions for their unique environments—designed to last, backed by certification.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com