Introduction

Surface finishing plays a vital role in the performance, durability, and visual appeal of stainless steel heat exchanger tubes. Two of the most widely used methods are:

- Pickling

- Bright Annealing (BA)

Each has unique characteristics, costs, and application suitability. In this article, DLSS compares these 2 popular finishing methods in 4 key areas to help you make an informed choice.

1. Surface Appearance

| Finish Type | Appearance |

|---|---|

| Pickled | Dull, matte gray, slightly rough |

| Bright Annealed | Shiny, smooth, mirror-like finish |

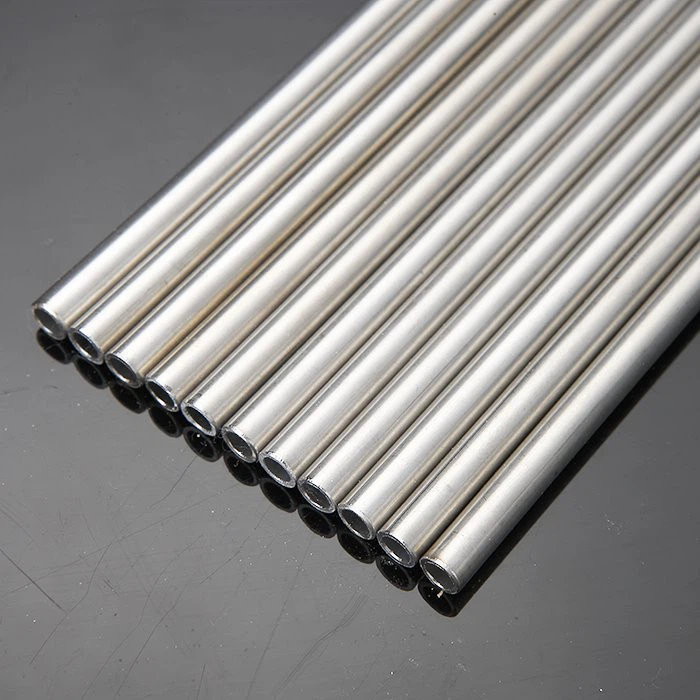

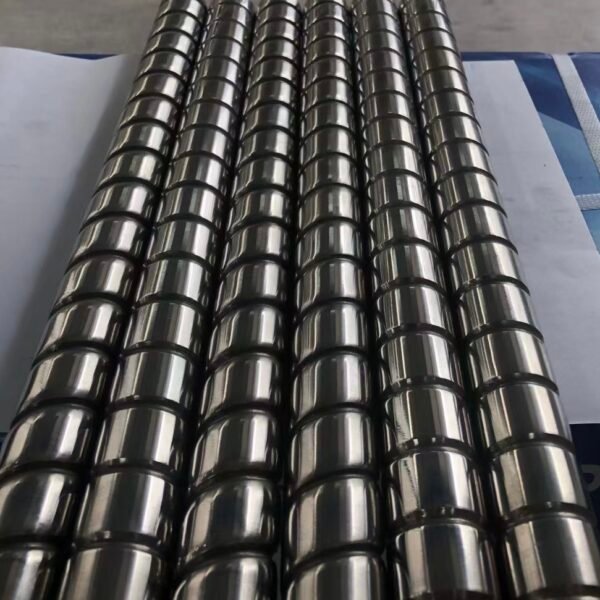

Pickling removes oxide scale and impurities using acid, leaving a clean but non-reflective finish.

Bright Annealing is done in a controlled hydrogen/nitrogen atmosphere, preserving a bright, polished surface.

Choose BA if aesthetics or hygiene is a priority.

2. Corrosion Resistance

Both finishes restore passive chromium oxide layers, but BA surfaces are:

- Smoother

- Less prone to pitting

- Easier to clean and sterilize

Bright Annealed tubes are often preferred for:

- Food & beverage lines

- Pharmaceutical systems

- Ultra-pure water applications

DLSS offers low Ra (<0.2μm) BA tubes for ultra-clean environments.

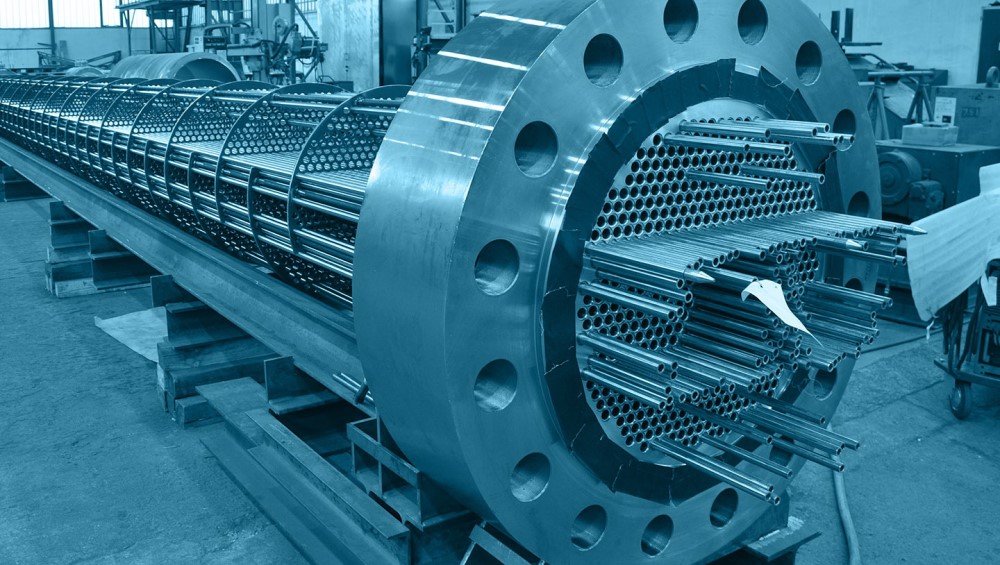

3. Application Suitability

| Application | Recommended Finish |

|---|---|

| General heat exchanger systems | Pickled |

| Petrochemical / Boiler piping | Pickled |

| Cleanroom / Sanitary use | Bright Annealed |

| Aesthetic tubing (visible areas) | Bright Annealed |

Pickled tubes are more cost-effective and suitable for most industrial systems.

Bright Annealed tubes are essential when hygiene or reflectivity is needed.

4. Cost & Production Complexity

Bright Annealing requires:

- High-precision atmosphere control

- Continuous annealing furnace

- Inert gas protection (hydrogen/nitrogen)

This makes it more expensive than acid pickling, which is simpler but more aggressive to the environment and surface.

DLSS offers both processes in-house, and helps you select based on project budget and end-use.

DLSS Surface Finishing Capabilities

DLSS manufactures pickled and bright annealed seamless stainless tubes in compliance with:

- ASTM A213 / A269 / A789

- ASME SA213 / SA789

- Customized Ra surface roughness

- Heat treatment and NDT reports included

Clean packaging available for sanitary-grade products. Tubes sealed with caps, air-dried, and plastic-wrapped to prevent contamination.

Conclusion

Both pickling and bright annealing are effective stainless steel surface treatments—but they serve different purposes.

If you’re working on sanitary, aesthetic, or ultra-clean systems, choose Bright Annealed.

For industrial-grade, cost-sensitive, or high-temperature systems, Pickled tubes are a smart choice.

DLSS helps you decide the right finish based on your application, cost constraints, and technical requirements.

Need Stainless Steel Tubes with the Right Surface Finish?

Our engineers can recommend the ideal surface treatment for your project—and deliver high-precision results.

Email us at: info@dlsspipe.com

Website: www.dlsspipeline.com