Selecting the right heat exchanger is critical for ensuring operational efficiency, durability, and cost-effectiveness. Among the most commonly used designs are the plate heat exchanger (PHE) and the shell and tube heat exchanger (STHE)—each offering distinct performance advantages in specific industrial environments.

This guide compares the two technologies in terms of structure, thermal performance, maintenance, and suitable applications to help you make informed engineering or procurement decisions.

What Are Plate and Shell-and-Tube Heat Exchangers?

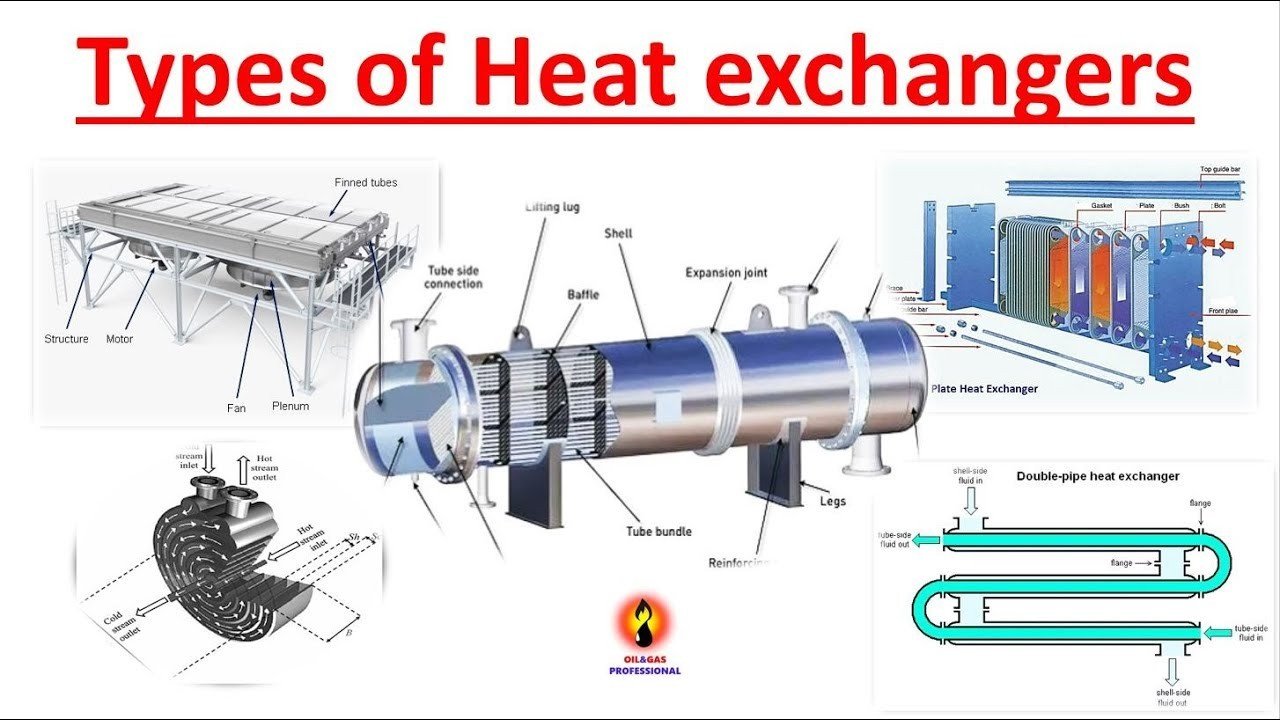

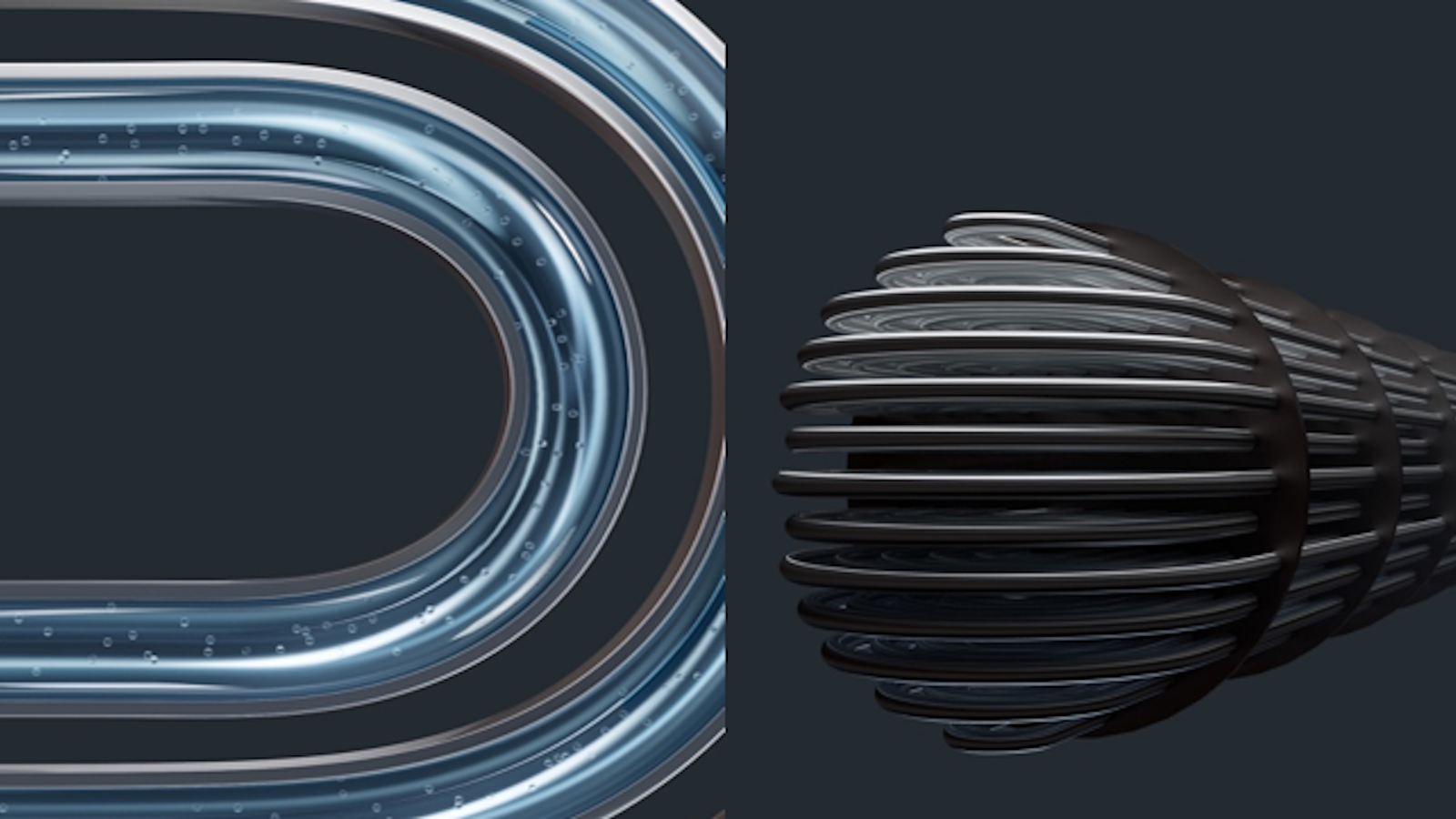

A plate heat exchanger is constructed using a series of corrugated metal plates, creating parallel flow channels for two fluids. This design offers a high surface area-to-volume ratio, making it highly efficient in compact applications.

A shell and tube heat exchanger consists of a bundle of tubes enclosed in a cylindrical shell. One fluid flows inside the tubes while another flows across them in the shell, allowing robust heat transfer even under high pressures and temperatures.

Technical Comparison: Plate vs. Shell and Tube

| Feature | Plate Heat Exchanger (PHE) | Shell and Tube Heat Exchanger (STHE) |

|---|---|---|

| Design | Corrugated plates with gaskets or brazed joints | Cylindrical shell + U-bend or straight tubes |

| Footprint | Compact, ideal for tight spaces | Larger, requires more installation area |

| Heat Transfer Rate | High due to large surface area | Moderate, dependent on surface area and flow configuration |

| Pressure Resistance | Limited (~25 bar for gasketed PHEs) | High (>100 bar), suitable for steam and oil processing |

| Temperature Range | Up to ~200°C (limited by gaskets) | >400°C possible with high-alloy materials |

| Cleaning & Fouling | Easy for clean fluids, prone to clogging with fouling | Handles dirty fluids well, allows mechanical cleaning |

| Maintenance Access | Easy plate disassembly (gasketed types) | Tube bundle removal or cleaning ports required |

| Applications | HVAC, food, pharmaceuticals, low-viscosity media | Power, petrochemical, steam, offshore, high-pressure systems |

| Initial Cost | Lower for small-to-medium systems | Higher upfront cost but long-term durability |

| Lifecycle Cost | May require frequent gasket replacements | Lower if well-maintained; fewer wear parts |

When to Choose Plate Heat Exchangers

Choose a plate heat exchanger if:

- Your process operates under moderate pressure and temperature

- Footprint size is a constraint

- Fluids are clean, low-viscosity, and non-particulate

- You require frequent cleaning or quick servicing

- Your industry involves HVAC, food processing, or pharmaceutical production

When to Choose Shell and Tube Heat Exchangers

Select a shell and tube exchanger when:

- The application involves high pressure or high temperature fluids

- Thermal expansion or corrosive media are key concerns

- The process uses dirty, fouling, or viscous fluids

- Your design must comply with standards like ASME Section VIII or API 660

- You operate in power plants, refineries, or chemical processing

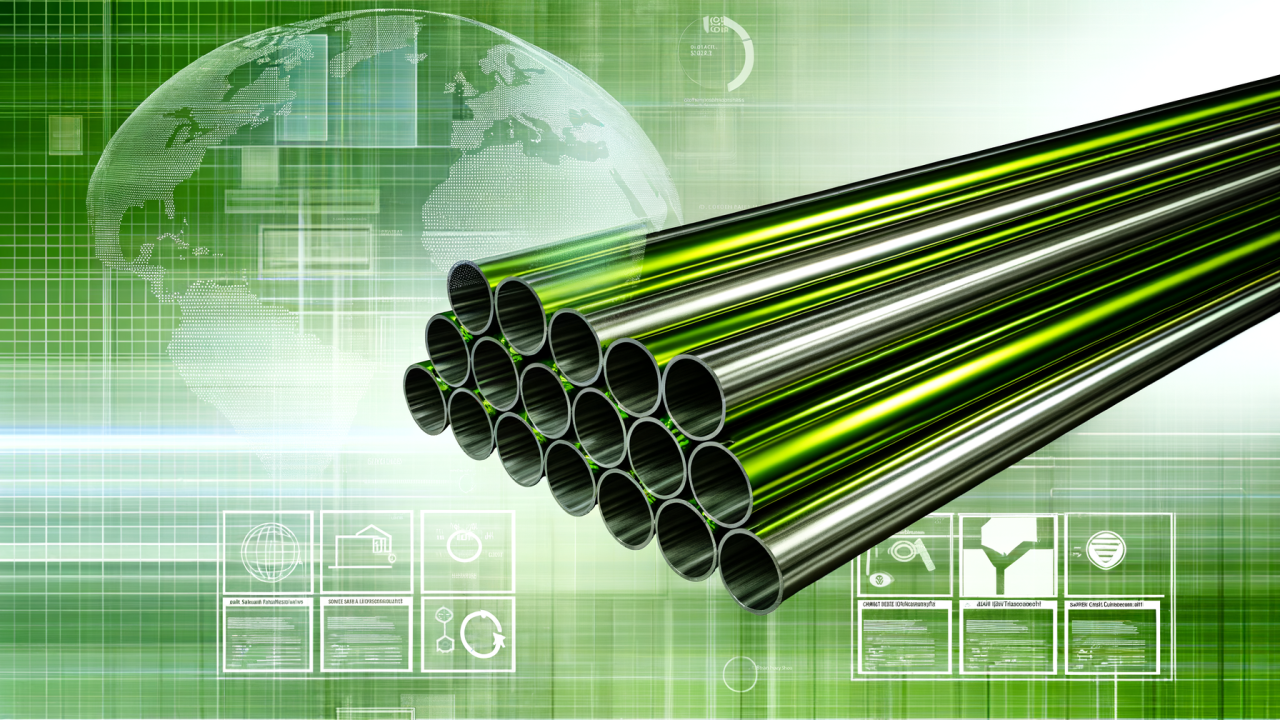

DLSS: Precision Tubes for Shell-and-Tube Heat Exchangers

At DLSS, we specialize in seamless stainless steel tubes for shell-and-tube heat exchangers used in mission-critical systems worldwide.

Our offerings include:

- Tubes in 304L, 316L, Duplex 2205, Super Duplex 2507, Titanium, and Nickel Alloys

- Cut-to-length service, U-bending, bright annealing, and polishing

- Compliant with ASTM A213, EN 10216-5, PED, and ASME

- Used in refineries, offshore platforms, boilers, and condensers

Frequently Asked Questions (FAQ)

Q1: Which exchanger type is more durable in corrosive environments?

Shell-and-tube units with high-alloy tubes (e.g., Duplex, Titanium) offer superior corrosion resistance and longer service life in aggressive media.

Q2: Can I replace a plate exchanger with a shell-and-tube one?

Only if space, pressure, and fouling conditions allow. Shell-and-tube units are more robust but require more room.

Q3: Which option is easier to clean and maintain?

PHEs are easier to open and clean for clean-service fluids. STHEs are more suitable for dirty service with mechanical cleaning tools.

Contact Us

Looking to specify or source heat exchanger tubes for your next project?

At DLSS (Zhejiang Daling Special Steel Co., Ltd.), we support OEMs, EPC contractors, and industrial end-users with:

- Technical consulting and material selection

- Fast and responsive quotations

- Global export service and full compliance documentation

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Partner with DLSS for high-performance stainless solutions engineered to last.