When it comes to industrial heat transfer equipment, shell and tube heat exchangers (STHE) and plate heat exchangers (PHE) are two of the most widely used technologies. Each design offers specific advantages and limitations depending on the industry, media properties, and operational conditions.

In this article, we’ll provide a professional comparison between STHE and PHE, highlighting their respective structures, performance characteristics, maintenance requirements, and typical application scenarios—helping engineers and procurement teams make informed decisions.

Definition and Working Principles

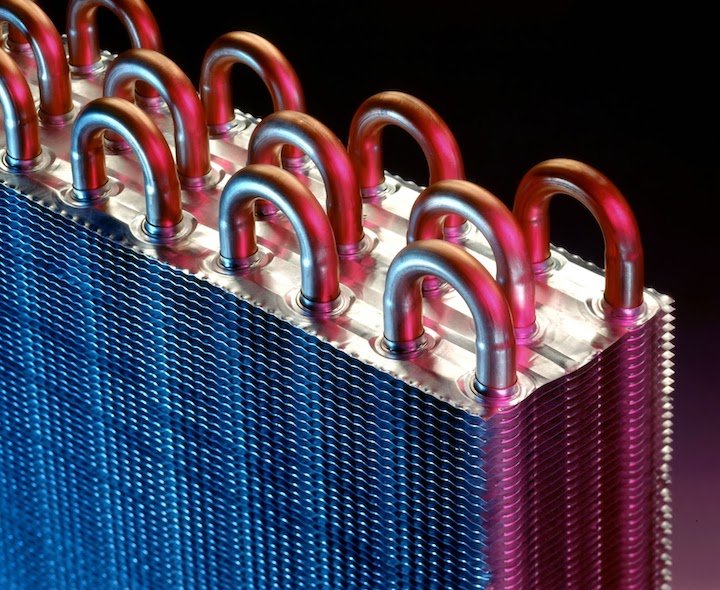

- Shell and Tube Heat Exchanger: A type of heat exchanger consisting of a bundle of tubes inside a cylindrical shell. One fluid flows inside the tubes while another flows over the tubes within the shell. More details: Wikipedia – Shell and Tube Heat Exchanger

- Plate Heat Exchanger: Made up of corrugated metal plates stacked together, forming channels for two fluids to flow in alternate directions. Offers compactness and high thermal efficiency. More details: Wikipedia – Plate Heat Exchanger

Technical Comparison: STHE vs. PHE

| Feature | Shell and Tube (STHE) | Plate Heat Exchanger (PHE) |

|---|---|---|

| Design Structure | Cylindrical shell + tube bundle | Stacked plates with gaskets or brazed joints |

| Footprint | Larger (requires more space) | Compact design, smaller footprint |

| Heat Transfer Area | Lower per unit volume | High surface area per volume |

| Pressure Resistance | Excellent; suitable for high-pressure systems | Limited in gasketed type; brazed PHEs better |

| Temperature Capability | Handles higher temperatures (over 400°C possible) | Up to ~200°C depending on material |

| Fouling Tolerance | More tolerant; easier for dirty/particulate fluids | Susceptible to clogging; requires cleaner fluids |

| Maintenance | Tube bundle removable for mechanical cleaning | Easy to disassemble and clean plates (gasketed type) |

| Applications | Oil & gas, power, chemical, steam condensers | HVAC, food & beverage, pharmaceutical, low-viscosity fluids |

| Initial Cost | Higher | Generally lower |

| Lifecycle Cost | Lower (durable, longer service interval) | May require frequent gasket replacement |

Application Scenarios

When to Choose Shell and Tube Heat Exchangers:

- High-pressure or high-temperature operations (e.g., steam, condensers)

- Dirty or fouling-prone fluids

- Large thermal loads

- Critical process reliability required

- Complies with ASME Section VIII, API 660

When to Choose Plate Heat Exchangers:

- Limited installation space

- Frequent cleaning or batch production

- Clean fluids (water, light oils, beverages)

- Compact skid-mounted systems

- Ideal for HVAC, food processing, pharmaceutical, and small-capacity utilities

DLSS Expertise in Shell and Tube Systems

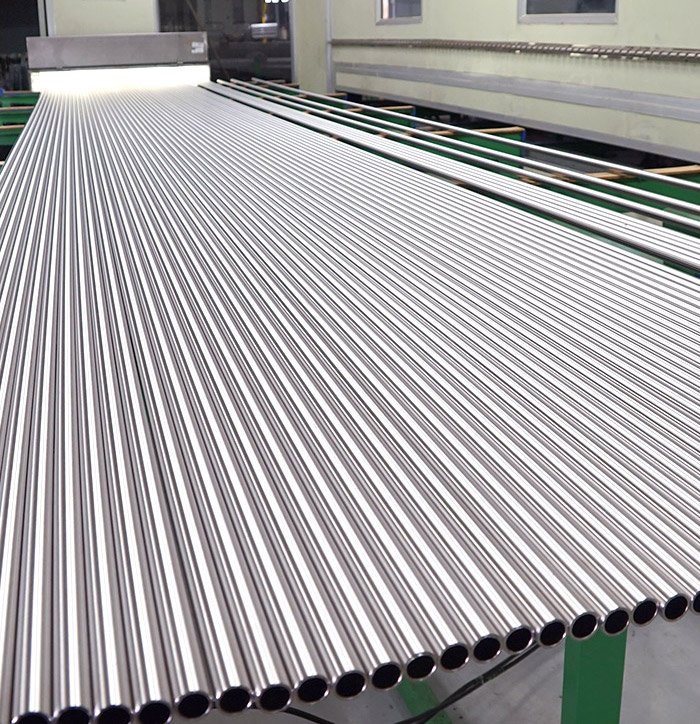

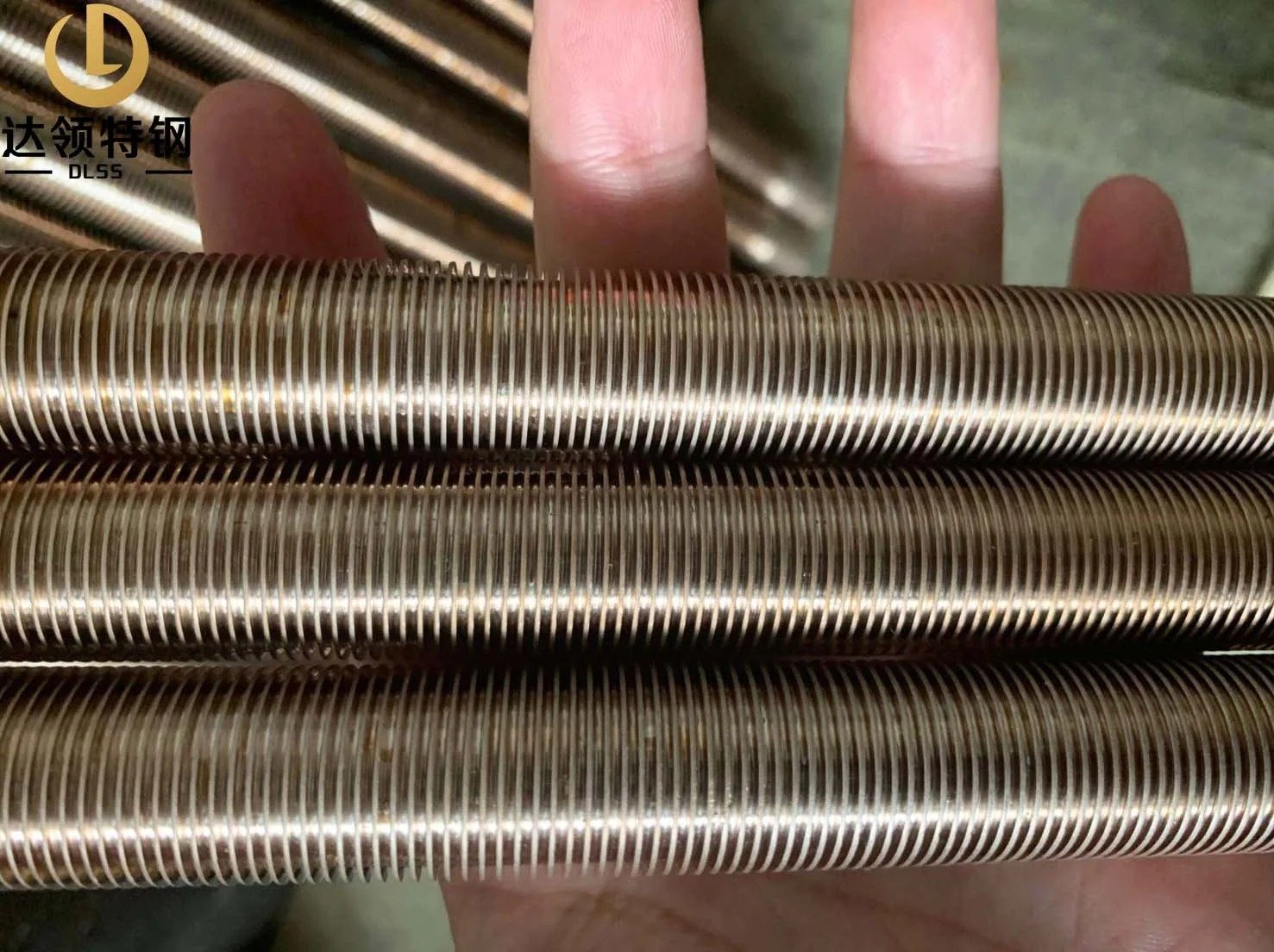

While both technologies serve important roles, DLSS focuses on high-performance tubular components for shell and tube heat exchangers. We supply:

- Seamless stainless steel tubes in 304L, 316L, Duplex, Super Duplex, Titanium, and Nickel Alloys

- U-bent tubes for condensers, power stations, and boilers

- Products compliant with ASME, EN 10216-5, PED, ASTM A213, and client-specific standards

- Engineering support for tube layout, tube sheet compatibility, and corrosion resistance recommendations

Explore our products:

DLSS Heat Exchanger Tube Solutions

Frequently Asked Questions (FAQ)

Q1: Can I replace a plate heat exchanger with a shell and tube one?

Yes, provided sufficient installation space is available and pressure/temperature design criteria are reviewed.

Q2: Which option is more durable in corrosive environments?

Shell and tube heat exchangers, particularly those using titanium or duplex tubes, are preferred in highly corrosive applications.

Q3: Which is easier to clean?

PHEs are easier to clean if fluids are clean and gaskets are in good condition. STHEs are better suited for mechanical cleaning in dirty fluid service.

Q4: Which offers better thermal efficiency?

PHEs have higher efficiency per footprint. However, STHEs are more robust under harsh conditions and offer longevity.

Contact Us

Need technical support selecting the right exchanger type or tubes for your project?

Email: info@dlsspipe.com

Website: https://www.dlsspipeline.com

Our engineering and export specialists are ready to assist with technical documentation, drawings, and custom tube production.