Introduction

The oil and gas industry in Japan demands high-precision stainless steel instrumentation tubing for safe and efficient operation of control systems. DLSS supplies JIS G3446-compliant tubes with excellent corrosion resistance, precision dimensional tolerances, and long service life in harsh offshore and onshore environments.

1. Why Stainless Instrumentation Tubes for Oil & Gas(石油・ガスにステンレス計装チューブが必要な理由)

- High Corrosion Resistance – withstands chloride-rich marine environments

- Dimensional Precision – critical for leak-free instrumentation systems

- Compatibility – works with Swagelok, Parker, and other leading fittings

2. Standards & Certifications(規格と認証)

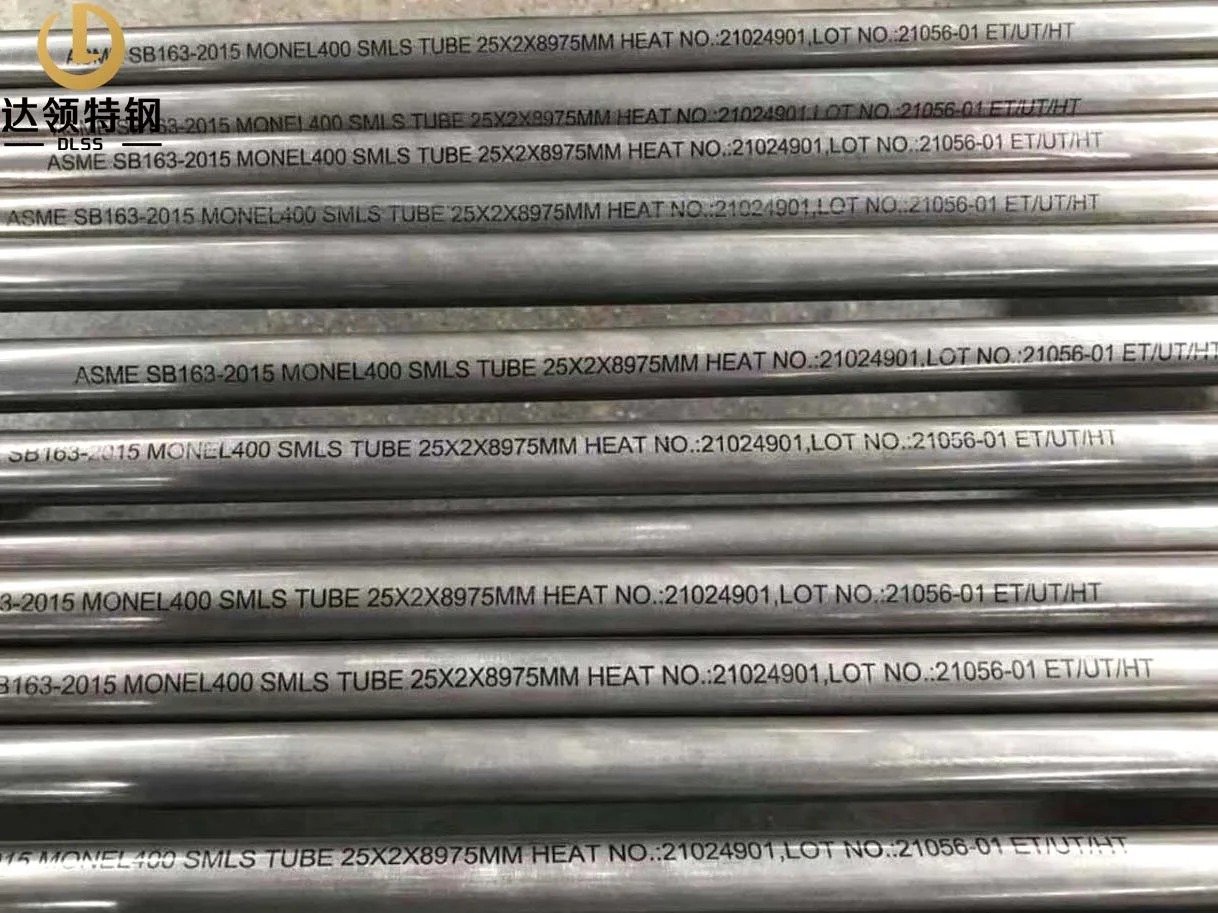

DLSS instrumentation tubes comply with:

- JIS G3446 – Stainless Steel Precision Tubes

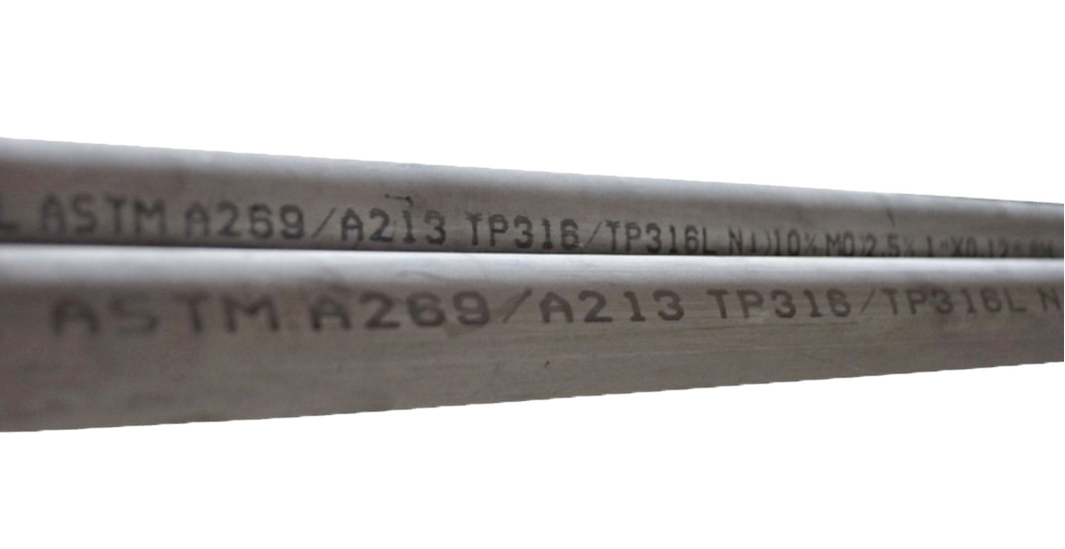

- ASTM A269 / ASTM A213 for global project compatibility

- 100% hydrostatic & eddy current testing

- Mill Test Certificates with heat number traceability

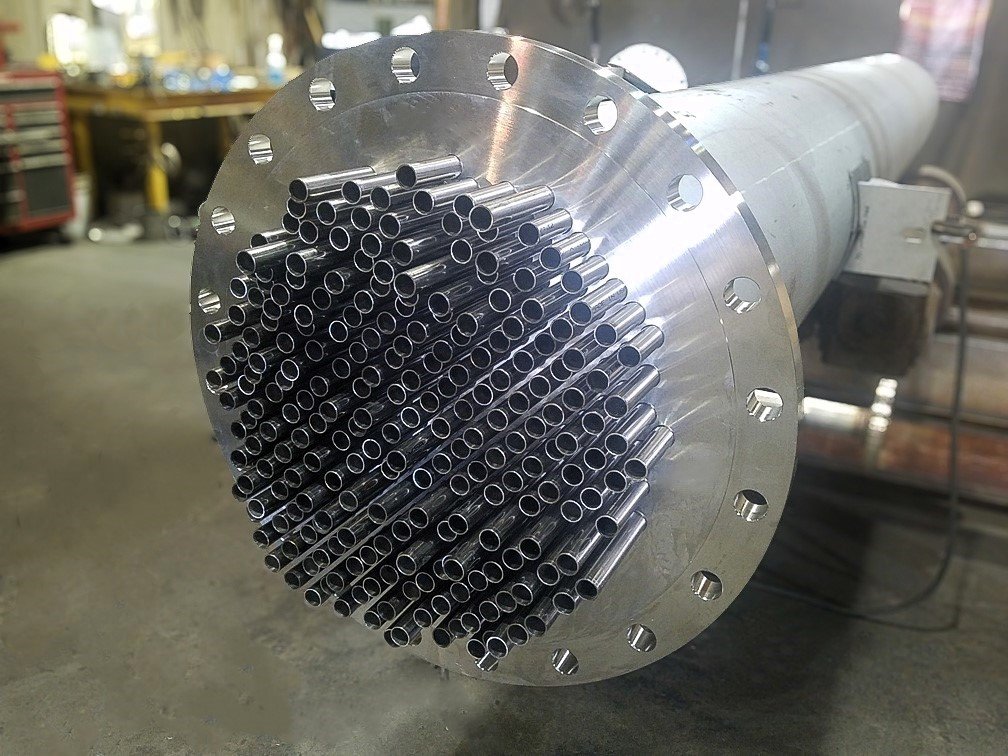

3. Common Applications in Japan(日本での主な用途)

- Offshore platform control lines

- Gas processing plant instrumentation

- Refinery measurement systems

- Subsea umbilical tubing assemblies

4. Packaging for Offshore Delivery(海上輸送用梱包)

- Seaworthy export packaging

- Coiled or straight lengths with capped ends

- Wrapped in moisture-proof film to prevent corrosion during transit

5. Why Japanese Oil & Gas Companies Choose DLSS(日本の石油・ガス企業がDLSSを選ぶ理由)

- Proven supply record for Japanese offshore EPC projects

- Ability to supply both seamless and welded instrumentation tubing

- Rapid delivery schedule to match shutdown and maintenance timelines

FAQ(よくある質問)

Q1: Which JIS standard applies to stainless steel instrumentation tubes?

A1: JIS G3446 for stainless steel precision tubes.

Q2: Can DLSS provide instrumentation tubes in both metric and inch sizes?

A2: Yes, we supply both metric and imperial sizes to meet project specifications.

Q3: What grades are most common for oil & gas instrumentation tubing?

A3: TP316/316L are most widely used for their chloride corrosion resistance.

Q4: Can DLSS provide tubing with special surface finishes for offshore projects?

A4: Yes, we offer bright annealed, polished, and passivated surfaces.

Q5: What is the lead time for supplying instrumentation tubes to Japan?

A5: Usually 35–50 days, depending on order volume and specifications.