Meta Description:

Explore the latest trends in stainless steel seamless pipe demand across South America. Learn which industries drive growth, preferred grades, and how DLSS supports regional projects.

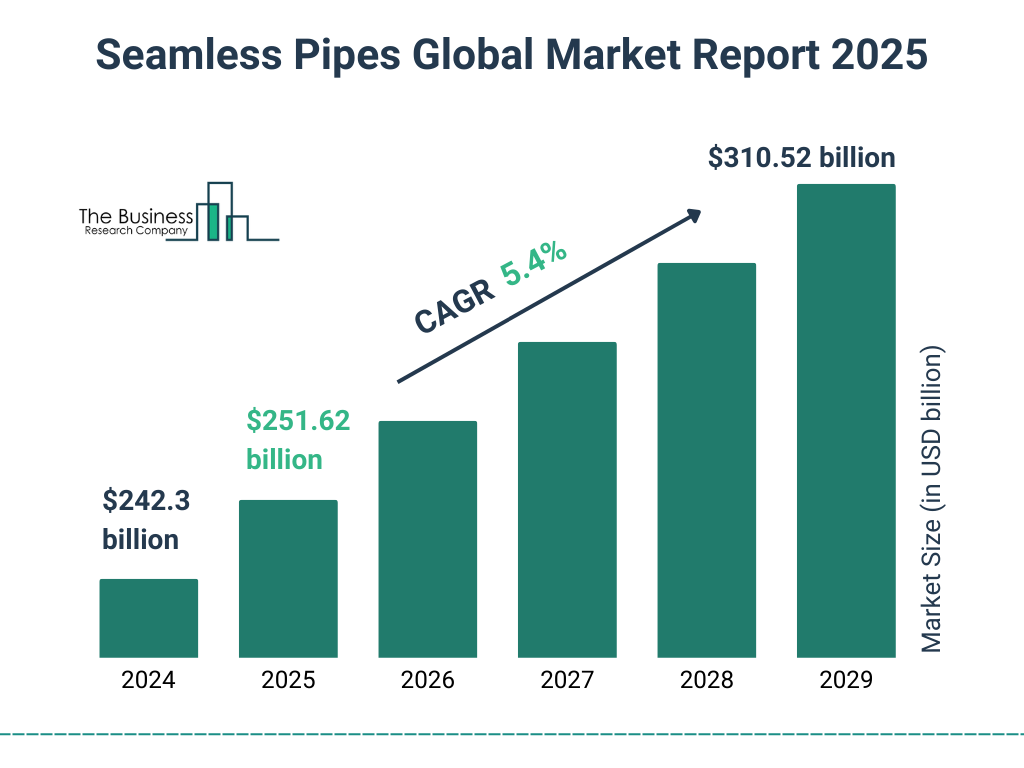

1. Market Overview in South America

South American demand for stainless steel seamless pipes has grown steadily, driven by:

- Refinery upgrades and petrochemical expansions in Brazil and Argentina

- Mining and mineral processing plants in Chile and Peru

- Biofuels, ethanol, and sugarcane industries in Brazil

- Infrastructure modernization and LNG terminal projects along the coast

Analysts report a 6–7% CAGR in the region through 2030, outpacing global averages.

2. Leading Application Industries

| Industry | Key Project Locations | Preferred Pipe Grades |

|---|---|---|

| Refining & Petrochem | São Paulo – Petrobras, PlataformAS Offshore | TP316L, TP347H, Alloy 825 |

| Mining & Minerals | Antofagasta (Chile), Lima (Peru) | Duplex 2205, Super Duplex |

| Biofuels & Ethanol | Center-South Brazil | TP316L, TP304L (food-grade) |

| LNG & Gas Processing | Cartagena (Colombia), Buenaventura (Colombia) | TP316L, Alloy 625, Duplex |

| Power & Utilities | Argentina, Ecuador | TP347H (boiler), Alloy 625 (high-temp system) |

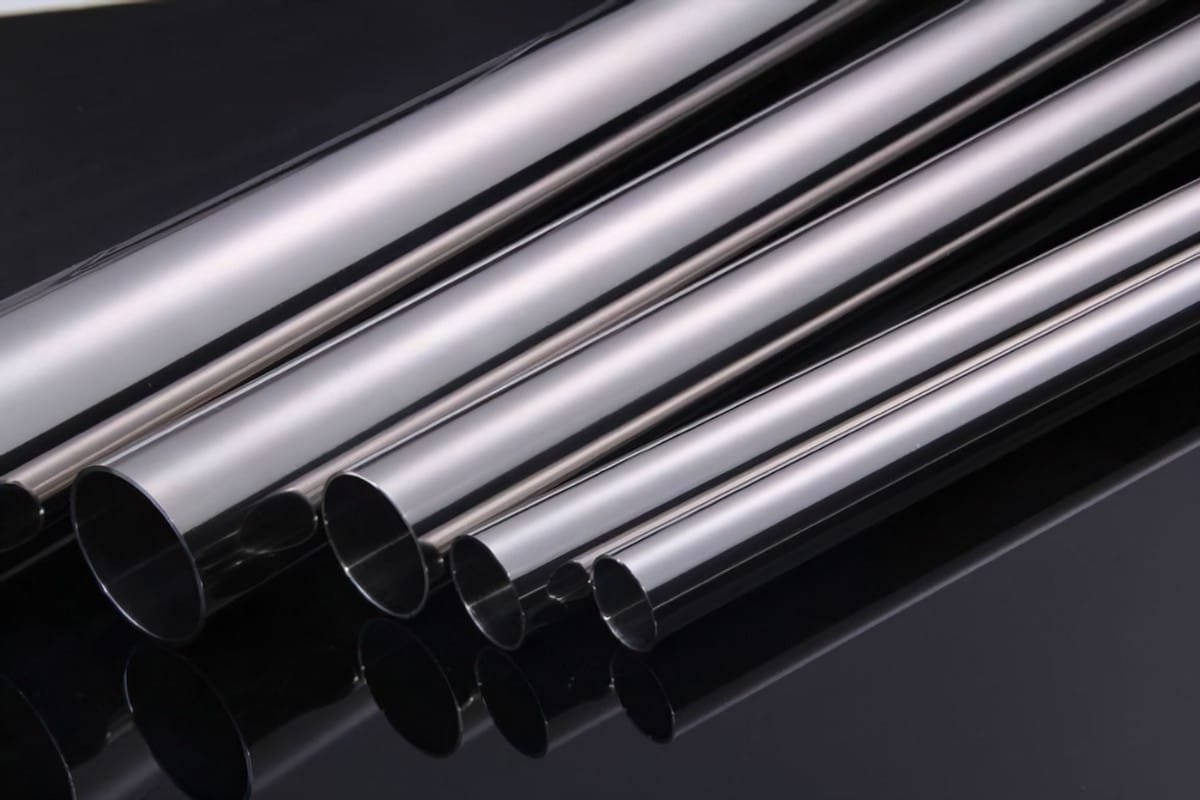

3. Preferred Pipe Grades

- TP316L: widely used in corrosive and food-grade applications

- TP347H: boiler and superheater circuits in power plants

- Duplex 2205: desalination, mining, offshore systems

- Alloy 825/Alloy 625: sour gas, acid recovery, hydrogen-capable plants

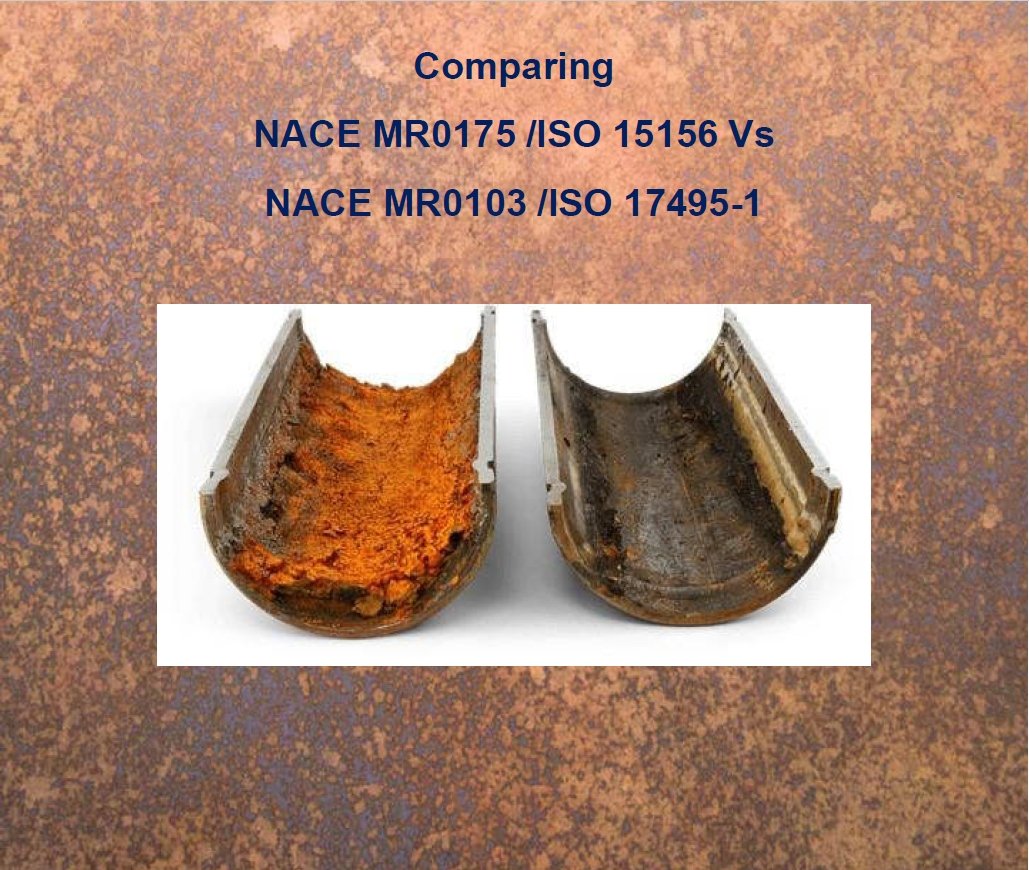

These grades are selected based on chloride exposure, pressure rating, and regulatory norms (NACE, ASME, EN).

4. Certification & Quality Demand

South American buyers increasingly require:

- EN 10204 3.2 certificates (especially for Brazilian and Argentine refinery EPC projects)

- NACE MR0175 compliance for sour service pipelines (Andean gas fields)

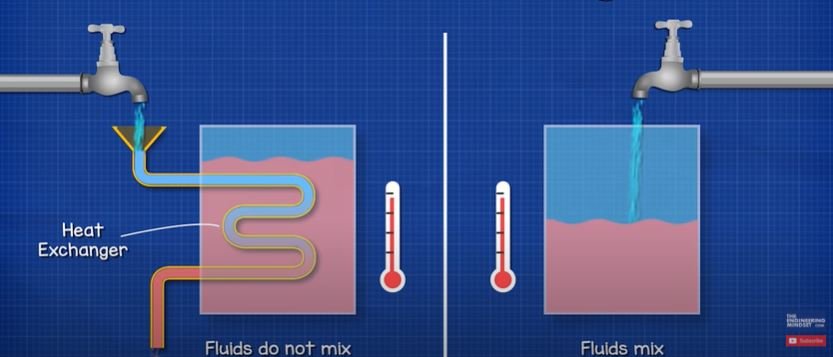

- Eddy current (EC) or ultrasonic (UT) testing, especially for high-pressure or heat exchanger tubes

- Pickled, BA, or electropolished finishes for sanitary, food, and LNG applications

5. Key Supply Chain Considerations

- Short lead times to key ports: Santos, Buenos Aires, Callao, Cartagena

- Batch traceability and bilingual MTC for customs and EPC audit

- Packaging for long-distance transit: sealed ends, nitrogen purge, dry packing

DLSS supports these needs with local export-ready stock and end-to-end logistics solutions.

6. Frequently Asked Questions (FAQ)

Q1: Which grades suit coastal LNG projects?

Duplex 2205 and Alloy 625 are ideal for seawater service; TP316L can also work in certain low-chloride setups.

Q2: Why is 3.2 certification growing in demand?

It provides independent verification required by Latin American EPCs and OEMs for critical infrastructure.

Q3: What finish is best for food and biofuel piping?

Bright Annealed (BA) or electropolished (EP) tubes with sanitary (ID) cleaning are commonly specified.

Q4: Does DLSS offer logistics support to South American ports?

Yes, DLSS provides customs documentation, export packaging, and port-ready shipping from your nearest export hub.

7. How DLSS Serves South America

- Regional stock of key grades (316L, 347H, Duplex, Alloy 825/625)

- Certificates: EN 10204 3.1/3.2, NACE MR0175

- Support for inspections by SGS, TÜV, BV

- Technical consulting in English, Spanish, Portuguese

- Logistics network covering major South American ports

Conclusion

South America is rapidly expanding its industrial infrastructure—especially in energy, mining, and food processing—creating strong demand for stainless steel seamless pipes.

By choosing DLSS, buyers benefit from right-grade materials, certification-ready documentation, local support, and optimized export logistics tailored for regional needs.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com