Meta Description:

Explore the critical requirements for stainless steel tubing in pharmaceutical and cleanroom applications. Understand surface finish standards, certifications, and DLSS’s high-purity solutions.

Introduction

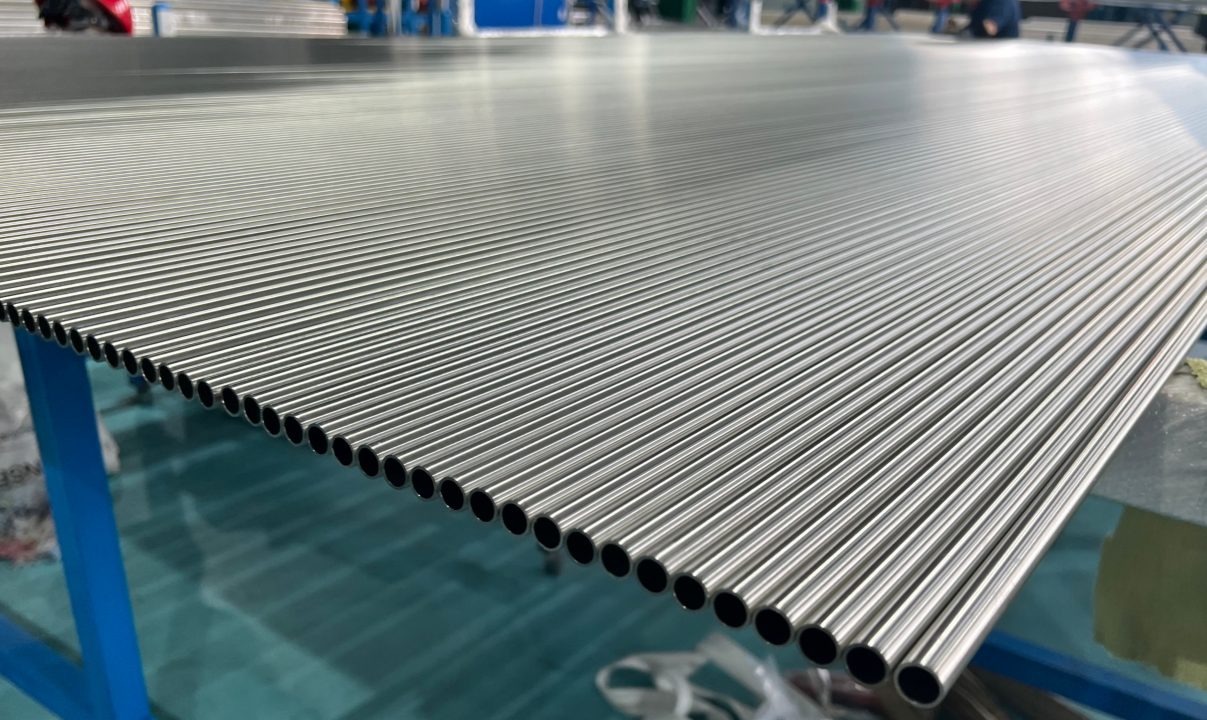

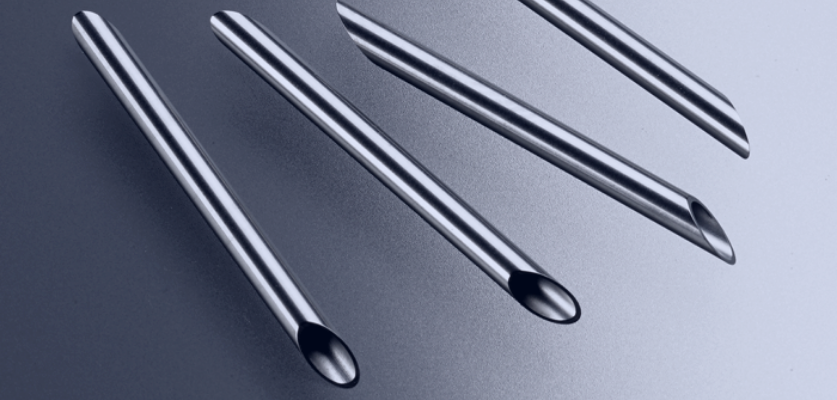

In pharmaceutical production and cleanroom environments, the cleanliness and surface integrity of stainless steel tubing are paramount. Even microscopic contamination can compromise product quality, regulatory compliance, or batch sterility.

DLSS manufactures high-purity stainless steel seamless tubes with surface finishes and certifications that meet the rigorous demands of pharma piping systems, WFI (Water For Injection) loops, and aseptic processing zones.

1. Why Tubing Matters in Pharma and Cleanrooms

- Product Contact: Tubing transports purified water, injectable solutions, solvents, gases

- CIP/SIP Compatibility: Tubes must withstand frequent chemical cleaning and steam sterilization

- Particulate-Free Flow: Internal Ra < 0.5 μm prevents bacterial adhesion or particle buildup

- GMP Compliance: Tubing materials are part of regulated critical systems (e.g., FDA, EU GMP)

2. Critical Surface Standards and Requirements

| Parameter | Standard Value | Importance |

|---|---|---|

| Ra (Roughness average) | ≤ 0.5 μm (standard), ≤ 0.25 μm (EP) | Prevents microbial growth, improves cleanability |

| Finish Type | Bright Annealed (BA), Electropolished (EP) | Required for hygienic and ultra-clean piping |

| Weld Bead Control | Flush or bead-rolled | Avoids dead legs and turbulence |

| Passivation | ASTM A967 or EN 10357 compliant | Enhances corrosion resistance |

All DLSS pharma-grade tubes are inspected visually and by profilometry (contact or laser Ra measurement) before shipment.

3. Applicable Standards and Certifications

| Standard | Application |

|---|---|

| ASTM A270 S2 | Sanitary tubing with controlled Ra and documentation |

| ASME BPE | Bio-processing equipment with dimensional and weld finish requirements |

| EN 10357 | Stainless steel tubes for food and pharma industry (EU) |

| ISO 1127 | Dimensional standards for stainless tubes |

| 3-A 63-03 | Tubing for dairy and pharma use |

Learn more: ASME BPE Guide – Bio-processing Equipment

4. DLSS High-Purity Tubing Capabilities

| Feature | DLSS Offering |

|---|---|

| Tube Grades | TP316L, TP316Ti, 1.4435, 1.4404, Alloy 22 |

| Surface Finish | BA standard, EP optional |

| Ra Certification | Available on request (contact or optical) |

| Tube Traceability | Laser-marked with heat number and grade |

| Documentation | EN 10204 3.1 or 3.2 MTC, with Ra + PMI + ET reports |

| Packaging | Cleanroom PE bags, foam-end cap, dust-free export carton |

5. Key Applications in Pharma Systems

| System | Tube Function |

|---|---|

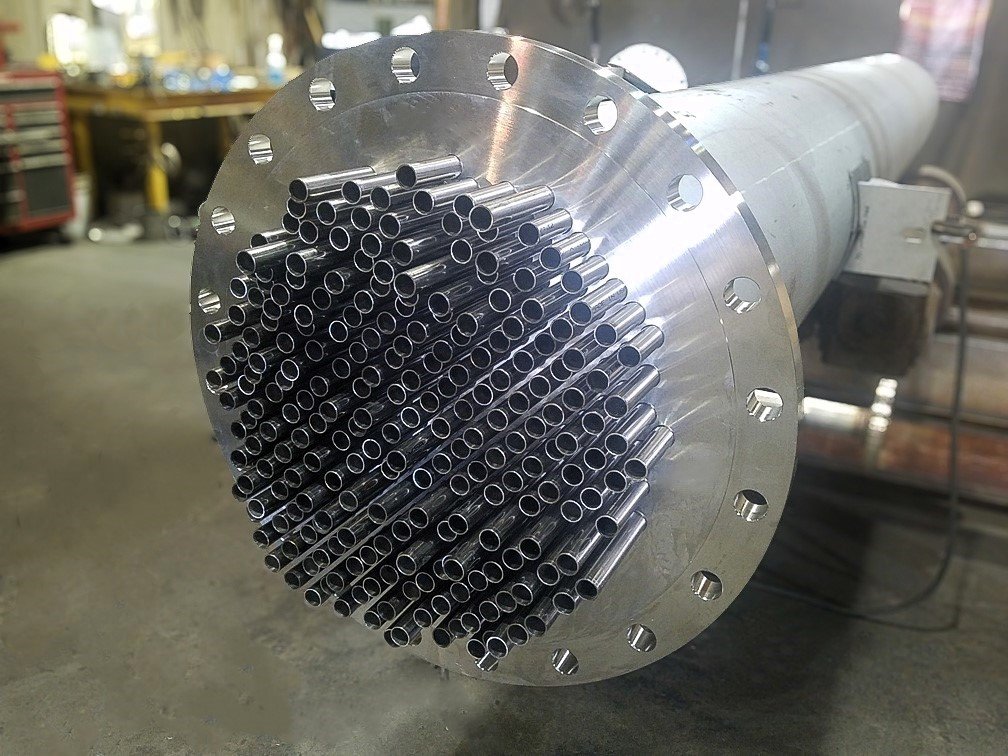

| WFI (Water for Injection) | Circulates sterile water at high temp and velocity |

| USP Purified Water | Delivers RO or deionized water |

| CIP/SIP Loops | Carries cleaning and sterilization media |

| API Transfer Lines | Solvents, liquids, and product batches |

| Compressed Gas Lines | Nitrogen, oxygen, clean air in aseptic zones |

6. Case Study: Biopharma Cleanroom in Southeast Asia

Client: Leading vaccine manufacturer

Project: Expansion of injectable facility cleanroom piping

Scope: 8,000 meters of 1.4435 seamless tubing

Specifications: ASTM A270 S2 + ASME BPE; EP finish Ra ≤ 0.25 μm

Testing: 100% Ra test, PMI, ET, ID video scope inspection

Result: Tubes passed FAT without issues. System certified by TÜV as GMP-compliant.

FAQs: Pharmaceutical Stainless Steel Tubing

Q1: What’s the difference between BA and EP tubing?

A: BA is oxide-free and smooth; EP goes further by electrochemically polishing the surface to Ra ≤ 0.25 μm and removing embedded particles.

Q2: What material is best for WFI lines?

A: TP316L or 1.4435 are most common, with EP finish preferred. Some critical lines use Alloy 22 for high chloride resistance.

Q3: Can DLSS tubes be used in ASME BPE systems?

A: Yes. DLSS provides tubes compliant with BPE dimensional and surface finish tolerances, with complete documentation.

Q4: What’s the cleanroom packaging method?

A: Tubes are bagged in PE sleeves, with end caps and shrink-wrap protection. Packing takes place in a controlled zone to prevent particulate ingress.

Conclusion

Pharmaceutical-grade stainless steel tubing requires more than just corrosion resistance—it demands documented purity, dimensional precision, and flawless surface finish.

DLSS supports pharmaceutical manufacturers and cleanroom integrators with stainless steel tubes engineered for GMP compliance, regulatory traceability, and long-term stability.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need EP-certified pharma tubing or assistance with GMP documentation? Contact DLSS for material samples, Ra certificates, and regulatory support.