Meta Description:

Discover the sanitary tubing requirements for food and beverage processing. Learn how stainless steel tubes ensure hygiene, corrosion resistance, and compliance with global standards.

Introduction

In the food and beverage industry, maintaining product purity, hygiene, and corrosion resistance is non-negotiable. Stainless steel tubing plays a critical role in transporting liquids and gases—from dairy to beer to syrups—without contamination.

DLSS provides seamless and welded stainless steel tubes that meet the strictest sanitary standards for dairy plants, brewery systems, juice lines, and automated clean-in-place (CIP) setups.

1. Why Stainless Steel Is Essential in Food-Grade Tubing

- Corrosion Resistance: Withstands acidic, alkaline, and chlorinated cleaning chemicals

- Hygienic Surface Finish: Smooth interiors prevent bacterial growth

- Durability: Long-lasting even under thermal cycling and repeated cleaning

- Non-Reactive: Does not leach into food or alter taste

- Easy to Clean: Supports automated CIP/SIP cycles

Reference: US FDA 21 CFR – Food Contact Materials

2. Global Standards for Food & Beverage Tubing

| Standard | Region/Country | Key Focus |

|---|---|---|

| ASTM A270 | USA / Global | Sanitary stainless tubing |

| 3-A 63-03 | North America | Dairy and milk processing tubing |

| DIN 11850 | Germany/EU | Metric-sized hygienic tubes |

| ISO 2037 | International | Food-grade stainless steel tubes |

| EHEDG | EU | Hygienic design in food equipment |

All DLSS sanitary tubes come with EN 10204 3.1 MTC, supporting full traceability and material conformance.

3. Recommended Grades for Food Use

| Grade | Typical Use | Notes |

|---|---|---|

| TP304 / 304L | General liquids, water, beer lines | Most economical, widely used |

| TP316 / 316L | Dairy, juice, cleaning chemicals | Better acid resistance (e.g. citric) |

| TP316Ti | High-temp CIP/SIP loops | Improved intergranular corrosion resistance |

| TP321 | Carbonated beverages, sugar concentrates | Stability under high temperature |

DLSS offers tubing in BA (Bright Annealed), pickled, or polished finish, suitable for both visible and sterile applications.

4. Surface Finish & Sanitation Requirements

Key Parameters for Hygienic Tubing:

- Ra (Roughness average):

- ≤ 0.8 μm for standard

- ≤ 0.4 μm for ultra-hygienic systems (optional EP finish)

- Weld Integrity:

- Orbital TIG welded

- Post-weld heat-treated or bead-rolled

- X-ray or dye penetrant tested (on request)

- Cleanliness:

- BA finish avoids scale or oxide

- Optional: Electropolished + passivated inner surface

5. Common Applications of Food-Grade Stainless Tubes

| Sector | Application |

|---|---|

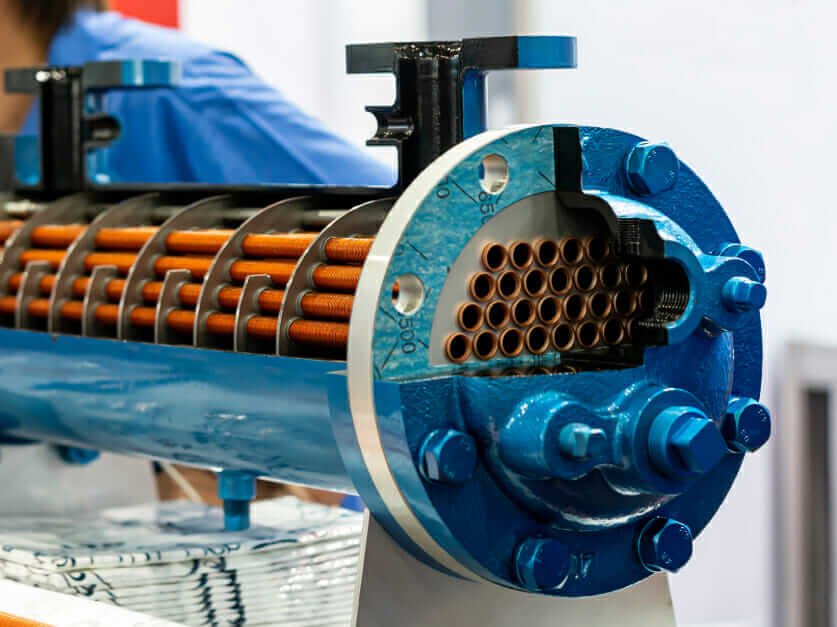

| Dairy | Milk cooling, whey transport, pasteurizer lines |

| Beverage | Beer, wine, juice, soda transport lines |

| Bakery / Confectionery | Syrup, chocolate, filling lines |

| Food Packaging | Sterile air, nitrogen injection, CO₂ lines |

| Frozen Foods | Glycol circulation, ammonia refrigerant systems |

Related: 3-A Sanitary Standards

6. Case Study: Juice Plant Installation in South America

Project: New orange juice plant installation in Brazil

Scope: 12,000 meters of TP316L sanitary tubes

Surface finish: BA with Ra ≤ 0.4 μm

Standards: ASTM A270, with 3-A marking

Testing: 100% PMI, ET, visual, and Ra certification

Outcome: Successful CIP validation, no contamination in 3-month trial

FAQs: Stainless Steel Tubing for Food Industry

Q1: What’s the difference between A270 and A269 tubing?

A: A270 is designed specifically for sanitary applications with stricter surface requirements; A269 is for general service.

Q2: Can DLSS supply tubing with 3-A certification?

A: Yes. We supply A270 tubes that meet 3-A 63-03 requirements, with full documentation and surface reports.

Q3: What are common sizes used in food applications?

A: Typically OD 1″ to 4″, with 1.65 mm (16SWG) or 1.5 mm WT. Metric sizes per DIN 11850 also available.

Q4: How to prevent bacterial contamination?

A: Use BA or electropolished tubes with Ra ≤ 0.5 μm, and ensure proper weld finishing. DLSS also offers orbital weld-compatible tube ends.

Conclusion

For the food and beverage industry, material hygiene, traceability, and long-term resistance are critical. DLSS delivers food-grade stainless steel tubes that comply with global sanitary standards—ensuring safety, taste preservation, and clean system design.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for sanitary stainless steel tubing? Contact DLSS for technical specs, surface inspection reports, and a quote tailored to your food-grade project.