Meta Description:

Understand the critical role of heat treatment in the manufacturing of stainless steel tubes. Learn about solution annealing, stress relieving, grain size control, and how these affect tube performance and quality.

Introduction

Heat treatment is not just a step in the production of stainless steel tubes—it is a fundamental quality determinant that affects corrosion resistance, mechanical strength, and long-term reliability.

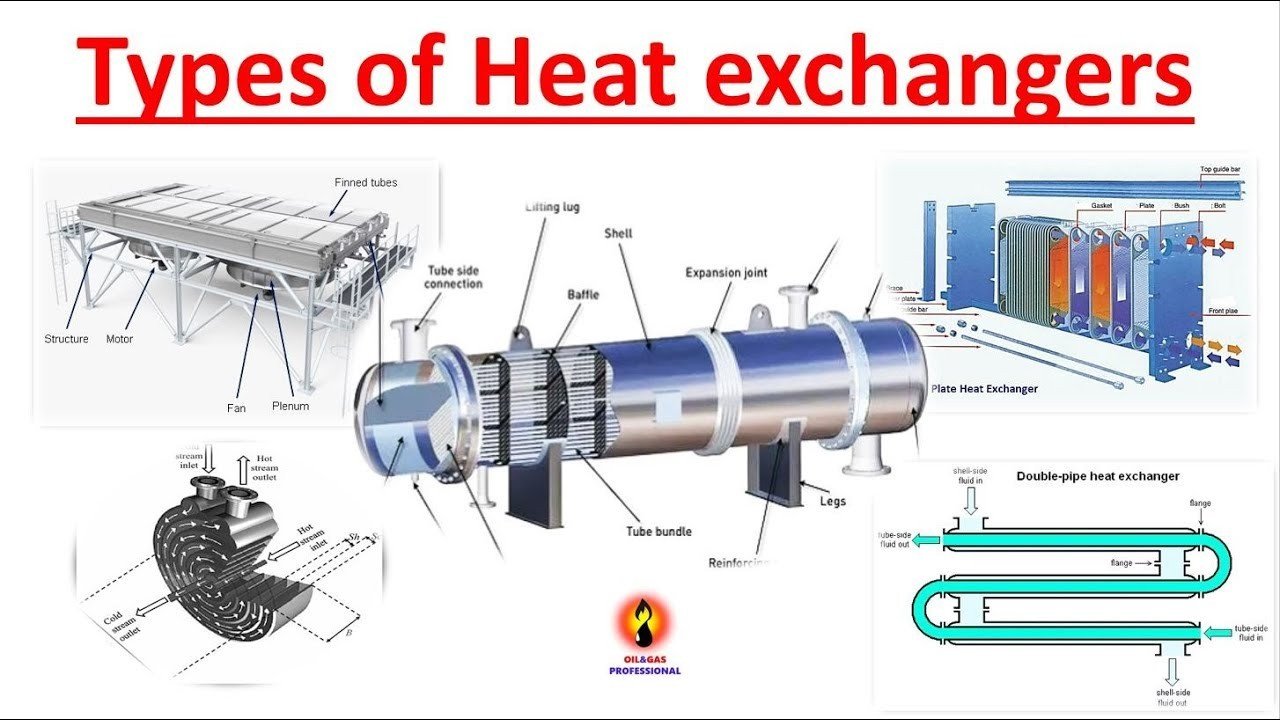

Whether you’re sourcing ASTM A213 heat exchanger tubes, duplex stainless pipes, or nickel alloy tubes, understanding the heat treatment process will help you ensure material integrity and compliance.

1. Why Heat Treatment Matters

Heat treatment in stainless steel tube production serves several purposes:

- Restore corrosion resistance (especially after cold working)

- Relieve internal stresses from forming or welding

- Refine grain size to ensure ductility and toughness

- Prevent intermetallic phase formation in duplex and nickel alloys

Failing to apply or verify proper heat treatment can lead to brittle failure, localized corrosion, and poor weldability in service.

2. Common Heat Treatment Methods for Tubes

| Process | Purpose | Typical Grades |

|---|---|---|

| Solution Annealing | Dissolves carbides and restores corrosion resistance | 304L, 316L, 321, 904L |

| Stress Relieving | Removes residual stresses from cold forming | Duplex, Incoloy, TP347 |

| Bright Annealing | Provides smooth, oxide-free finish in inert atmosphere | BA tubes (ASTM A269) |

| Normalizing | Refines grain size, improves uniformity | Ferritic stainless (TP430) |

| Aging (Precipitation Hardening) | Enhances hardness and yield strength | 17-4PH, 15-5PH |

3. Solution Annealing – The Foundation for Austenitic Tubes

- Typically performed at 1050–1150°C, followed by rapid water or air quenching

- Removes strain-induced martensite and carbides

- Critical for TP316L, TP321, TP904L, and other austenitic stainless tubes

- Post-bending U-tubes for heat exchangers must be re-annealed per ASTM A213/A269

Key Keywords: solution annealing tube, heat exchanger tube annealing, ASTM A213 tube heat treatment

4. Stress Relieving in Duplex and High-Alloy Tubes

Duplex stainless steels (e.g., S32205, S32750) and nickel alloys (e.g., Inconel 625, Alloy 825) are highly sensitive to improper heat input during bending or welding.

- Heat treatment prevents intermetallic phase formation (σ-phase, chi-phase)

- Ensures balanced ferrite-austenite structure

- Temperature typically ranges from 850–950°C, followed by controlled cooling

Welding duplex tubes without proper post-fabrication heat treatment can result in localized cracking or reduced toughness.

5. Bright Annealing: Clean Surface + Preserved Quality

- Conducted in controlled atmosphere furnaces (H₂ or N₂-H₂ mixture)

- Leaves surface bright and oxide-free

- Ideal for instrumentation tubes, BA finish coils, and pharma-grade tubing

Bright Annealed tubing is widely used in semiconductor, biotech, and high-purity process systems.

6. Grain Size Control & Testing

Fine, uniform grain size (typically ASTM No. 6–8) improves:

- Ductility

- Formability

- Resistance to intergranular corrosion

ASTM E112 is the standard test method for evaluating grain size. MTCs for heat exchanger tubes often include grain size verification, especially for nuclear or petrochemical projects.

Learn More: ASTM E112 Standard Overview

7. DLSS Capabilities in Heat Treatment

At DLSS, all stainless steel seamless tubes are fully heat-treated in-house using:

- Hydrogen bright annealing furnaces (for BA tubes)

- Electric resistance or gas furnaces (for U-bend post-treatment)

- Verified temperature records and time-at-temperature logs

- Grain size reports, hardness, and PMI results available on request

Conclusion

Heat treatment is not a one-size-fits-all process—it must be tailored to the tube material, application, and international standard. For engineers and purchasing teams, verifying that tubes have undergone proper annealing or stress relief is essential for performance, safety, and code compliance.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for stainless tubes with certified heat treatment? DLSS delivers ASTM and EN standard tubes with full thermal traceability and documentation.