Meta Description:

Discover how stainless steel tubes power the transition to renewable energy. Explore their critical applications in solar thermal systems, wind turbine cooling, and hydrogen infrastructure.

Introduction

As the global push for carbon neutrality intensifies, renewable energy systems are expanding at an unprecedented rate. From solar thermal plants to hydrogen pipelines, the infrastructure behind green energy demands materials that offer durability, corrosion resistance, and long life cycles under harsh environments.

DLSS provides high-grade stainless steel tubes that support mission-critical operations in solar, wind, and hydrogen power—where failure is not an option.

1. Why Stainless Steel Is Essential in Green Energy

| Requirement | Stainless Steel Advantage |

|---|---|

| High temperature resistance | Ideal for solar thermal & electrolyzers |

| Corrosion resistance | Handles marine air, aggressive chemicals |

| Pressure tolerance | Used in hydrogen transport, heat exchangers |

| Long service life | Supports infrastructure with >20-year lifespan |

| Sustainability | 100% recyclable and low lifecycle emissions |

Reference: World Stainless Association – Stainless for Sustainable Energy

2. Applications in Solar Energy

a) Solar Thermal Power Plants (CSP)

Stainless steel tubes are used in:

- Heat transfer fluid loops (HTF)

- Steam generator coils

- Thermal storage heat exchangers

Recommended Grades:

- TP316L, TP321H for high-temp resistance

- Incoloy 800H (UNS N08810) for molten salt systems

b) Solar Water Heating Systems

In residential/commercial setups, tubes must:

- Resist internal scaling and corrosion

- Support high pressures and outdoor exposure

Typical Material:

- TP304/316 with Bright Annealed or polished finish

3. Applications in Wind Energy

a) Cooling Systems in Wind Turbines

Modern wind turbines use active cooling for:

- Gearboxes

- Generators

- Power converters

Stainless steel tubes are used for:

- Heat exchanger coils

- Coolant loops

- Condensate drains

Challenges Faced:

- Vibration fatigue

- Salt spray (offshore turbines)

- Low ambient temperatures

Best Materials:

- TP316Ti, TP444, Duplex 2205

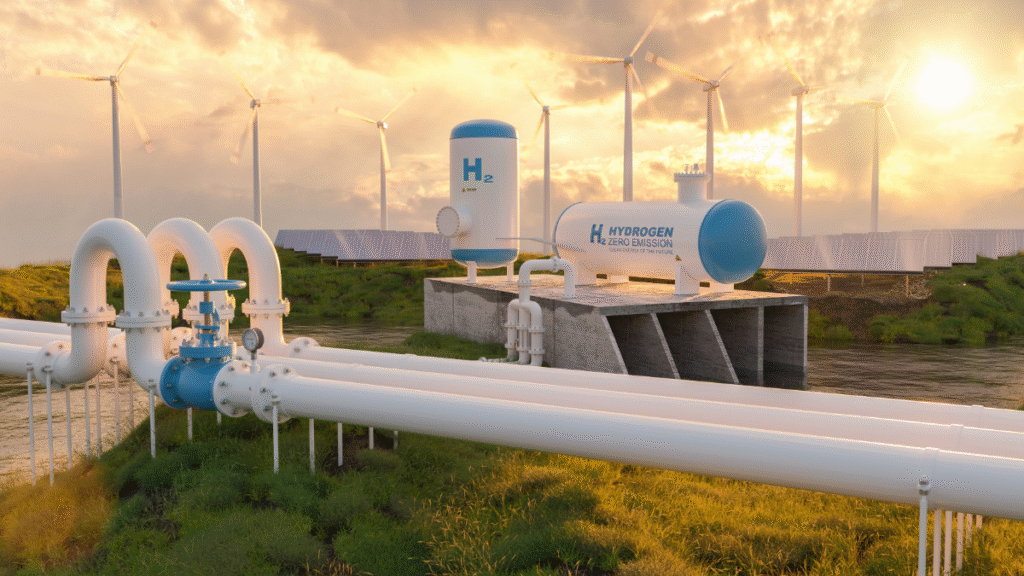

4. Applications in Hydrogen Systems

a) Hydrogen Production (Electrolyzers)

Stainless steel tubes must resist:

- Highly pure water

- Oxygen and hydrogen gases

- Electrolytic chemicals

Preferred Materials:

- 1.4404 / TP316L for PEM electrolyzers

- Alloy 825 or 254SMO for alkaline/acidic environments

b) Hydrogen Storage & Distribution

Stainless steel seamless tubes are used for:

- High-pressure hydrogen transport (up to 700 bar)

- Compressor units

- Fueling station pipework

Standard Compliance:

- ISO 11114-1: Hydrogen compatibility

- EN 10216-5 TC2: Pressure tubes

- ASME B31.12: Hydrogen piping systems

Read more: Hydrogen Europe – Infrastructure Needs

5. DLSS’s Technical Advantages in Green Energy Projects

| Feature | DLSS Solution |

|---|---|

| High-temperature grades | TP321H, Incoloy 800H, 347H |

| Corrosion resistance | Duplex 2205, 2507, 254SMO |

| Precision forming | U-bent tubes for compact exchangers |

| Certifications | EN 10204 3.1/3.2, NACE MR0175, PED, AD2000 |

| Testing & QA | ET, PMI, grain size, hydrotest, hydrogen embrittlement tests |

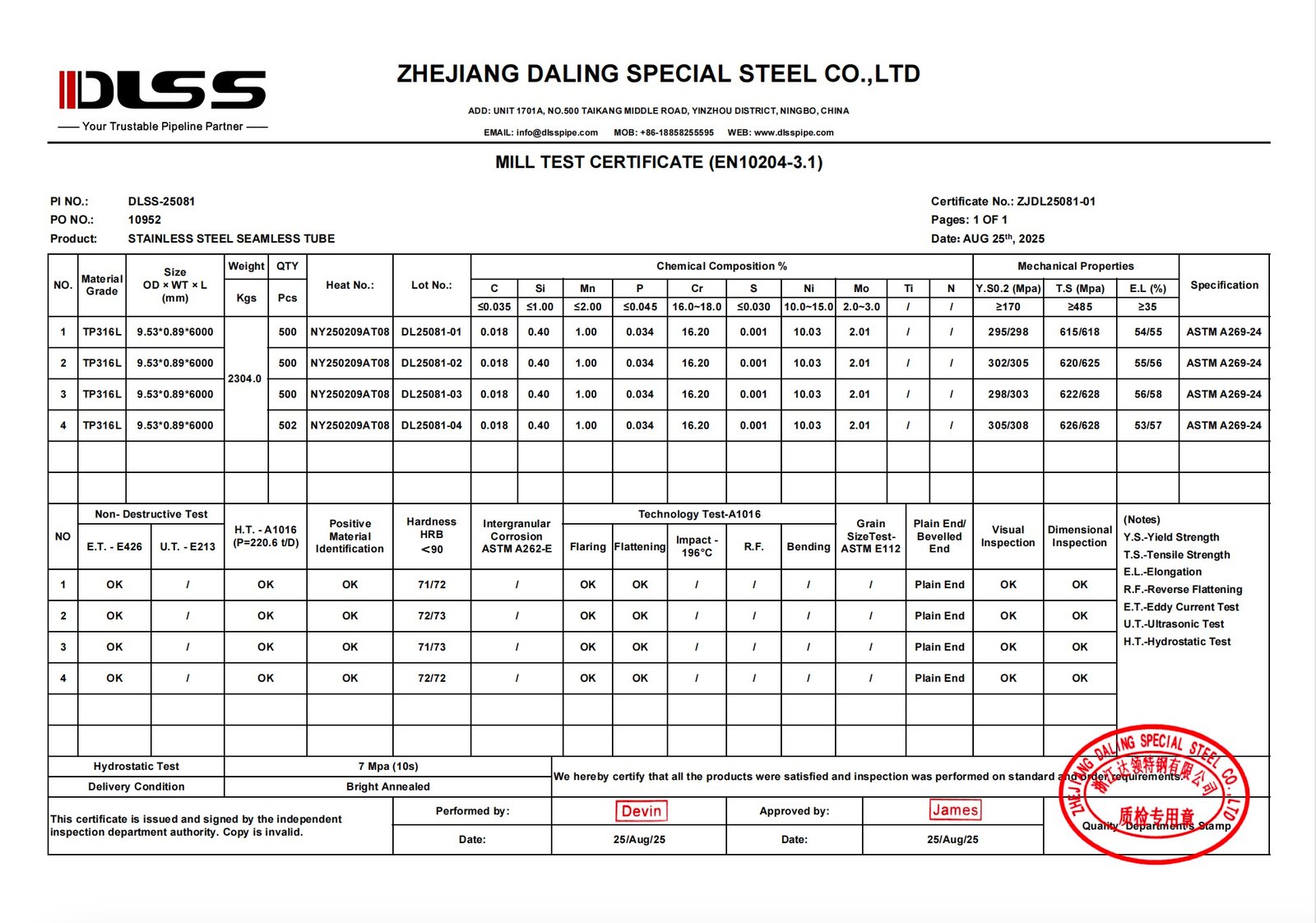

Case Study: Hydrogen Pilot Plant in the Middle East

Scope: 2,000 meters of TP316L + Alloy 825 seamless tubing

Application: Electrolyzer + compression system

Pressure Rating: 300 bar, ISO 11114 compliant

Features: BA finish, hydrotested, helium leak-tested

Outcome: Operational stability confirmed after 12-month commissioning

FAQs: Stainless Steel Tubes in Renewable Energy

Q1: Can standard stainless steel handle hydrogen exposure?

A: Yes, certain grades like 316L and Duplex can be used at low-to-medium pressure. For high pressure, hydrogen-compatible materials tested to ISO 11114 are required.

Q2: Which grade is best for solar thermal systems?

A: TP321H and Incoloy 800H are recommended due to their high-temperature creep resistance.

Q3: Are stainless tubes suitable for offshore wind turbines?

A: Absolutely. DLSS recommends Duplex 2205 or 2507 for superior resistance to salt spray and fatigue.

Q4: Does DLSS support custom tube forming for exchangers?

A: Yes. We supply U-bend, coil, and serpentine formats with post-forming annealing and inspection.

Conclusion

As the energy sector transforms, stainless steel tubing will be at the heart of clean energy systems. Whether in solar, wind, or hydrogen, DLSS delivers high-performance, sustainable tubing solutions that meet today’s toughest engineering challenges.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Planning a renewable energy project? Contact DLSS to discuss material options, technical datasheets, or hydrogen-compliant tube systems.