1. Introduction

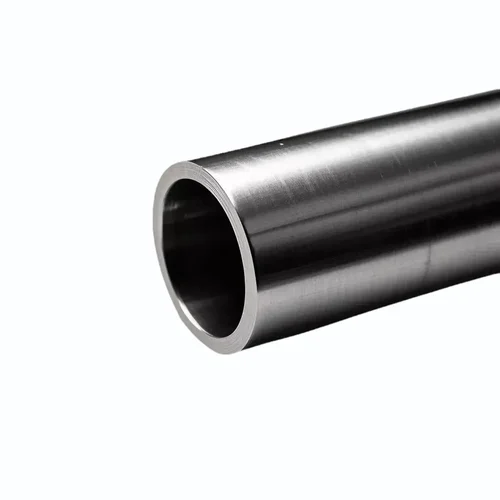

Seawater desalination projects are expanding rapidly across the Middle East, North Africa, and Asia, with a market size of over 25 billion USD. One of the most critical components in desalination plants is the condenser and heat exchanger tubing, where Titanium Grade 2 (GR2) tubes are the preferred material. With unmatched corrosion resistance in chloride-rich environments, Titanium GR2 condenser tubes ensure long service life and reliability in desalination facilities.

2. Properties of Titanium Grade 2

- Standard Reference: ASTM B338 / ASTM B861

- Material Characteristics:

- High corrosion resistance against seawater and brine.

- Excellent formability and weldability.

- High strength-to-weight ratio with low density (lightweight yet durable).

- Corrosion Resistance:

- Resistant to pitting, crevice corrosion, and stress corrosion cracking.

- Superior performance compared to stainless steel and copper alloys in seawater systems.

Learn more on Titanium – Wikipedia.

3. Why Titanium GR2 is Used in Desalination Plants

Desalination plants operate under harsh conditions with constant exposure to seawater and high chloride content.

Key reasons for choosing Titanium GR2 tubes:

- Long service life (20–30 years) with minimal maintenance.

- Resistance to biofouling and scaling.

- Reduced downtime and lower total lifecycle cost compared with stainless steel.

- Proven performance in thousands of desalination units worldwide.

4. Applications in Desalination Systems

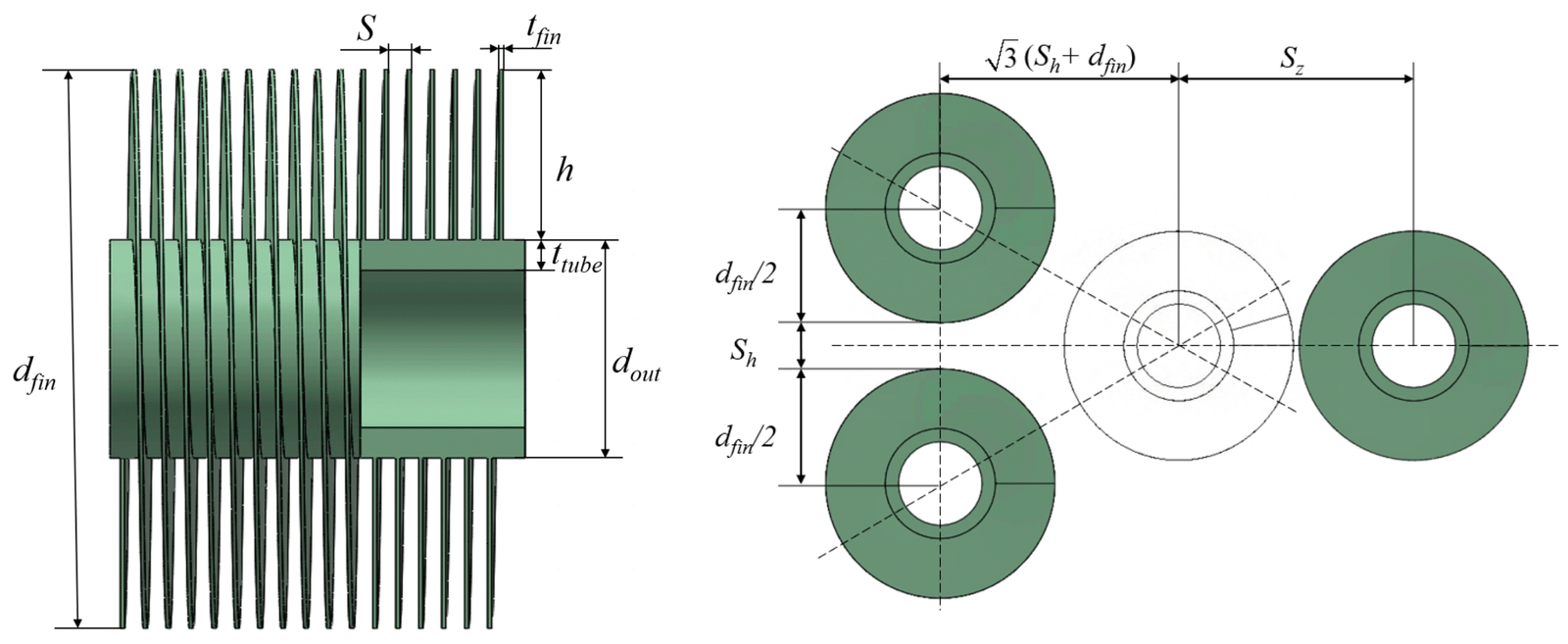

- Condenser tubes in multi-stage flash (MSF) distillation units.

- Heat exchanger tubes in multi-effect distillation (MED) plants.

- Seawater cooling systems for reverse osmosis (RO) plants.

- Brine heaters in high-temperature evaporation systems.

Reference: ASTM B338 Titanium Tubes Standard.

5. Titanium GR2 vs Other Materials

| Property / Feature | Titanium GR2 | Stainless Steel (316L) | Copper-Nickel (CuNi 90/10) |

|---|---|---|---|

| Corrosion Resistance in Seawater | Excellent | Moderate (risk of pitting) | Good |

| Service Life | 20–30 years | 5–10 years | 10–15 years |

| Weight (Density) | Very Light | Medium | Heavy |

| Cost | Higher upfront | Lower upfront | Moderate |

| Lifecycle Cost | Lowest | Higher (frequent replacement) | Medium |

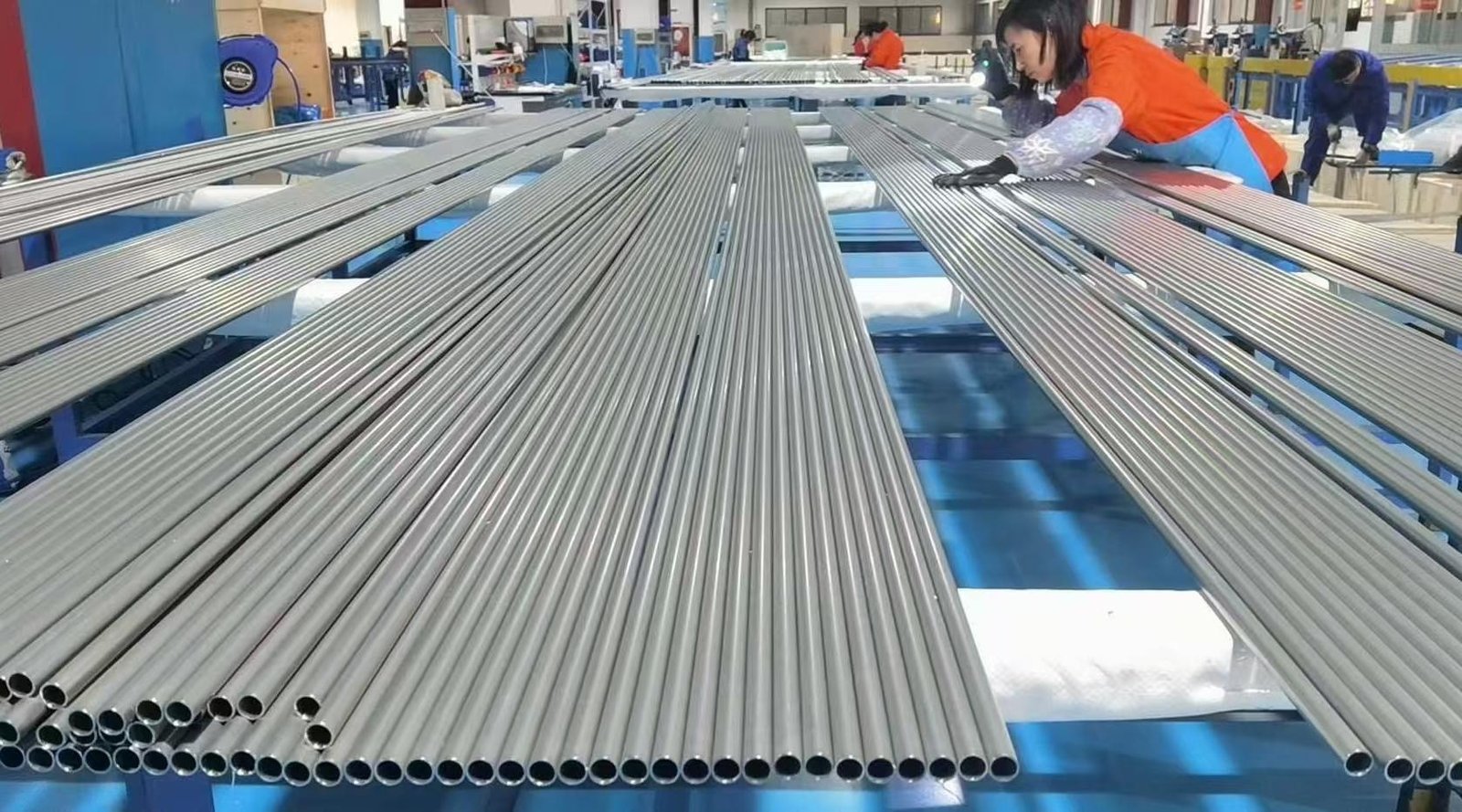

6. DLSS Titanium Tube Supply Advantages

At DLSS, we provide Titanium GR2 condenser tubes that meet international standards for desalination projects:

- Compliance with ASTM B338 / B861 and PED certification.

- Third-party inspection (TÜV, DNV, LR, ABS) available.

- Supply in straight lengths, U-bent tubes, and custom dimensions.

- Seaworthy export packaging: wooden crates, capped ends, anti-corrosion coating.

- Proven experience supplying tubes for power plants, desalination projects, and heat exchanger manufacturers.

7. Conclusion & Call to Action

With the global demand for desalination growing, Titanium GR2 condenser tubes have become the industry standard for reliability, durability, and long-term cost savings. For EPC contractors, equipment manufacturers, and end-users, Titanium GR2 ensures that critical seawater systems run smoothly and without unexpected failures.

Contact DLSS today for technical support and quotations.

info@dlsspipe.com | www.dlsspipeline.com