Meta Description:

Compare titanium tubes and stainless steel tubes in terms of corrosion resistance, mechanical strength, cost, and applications. Find out which is the better material for your heat exchanger or industrial system.

Introduction

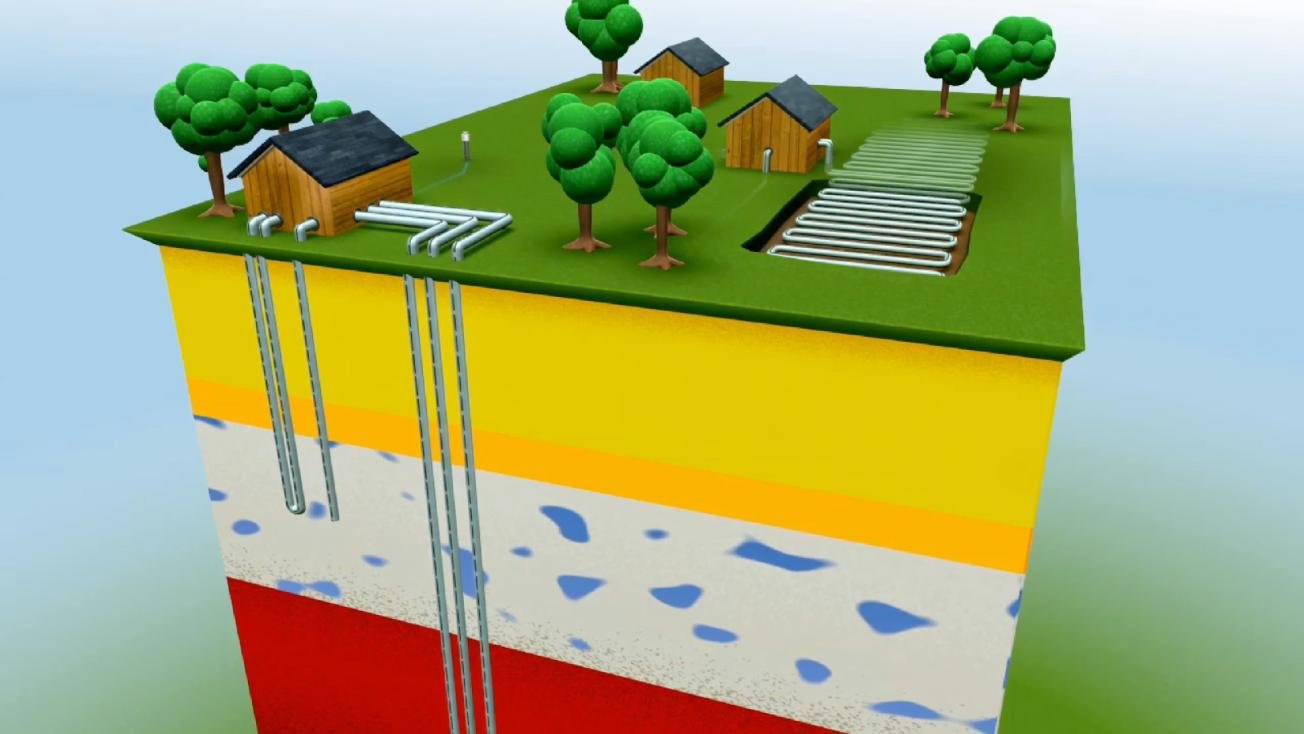

In corrosive or high-performance environments—such as desalination, chemical processing, or marine applications—material selection is crucial. Two common choices for heat exchanger tubing are titanium and stainless steel. But how do you choose the right one?

This article compares these two materials across key performance metrics: corrosion resistance, thermal conductivity, strength, price, and suitability for different industries.

1. Corrosion Resistance

Titanium Tubes

- Excellent resistance to seawater, chlorides, and most acids

- Forms a strong passive TiO₂ film, self-healing in the presence of oxygen

- Resistant to crevice corrosion and microbiologically influenced corrosion (MIC)

Learn more about titanium corrosion performance

Stainless Steel Tubes

- Grades like 316L, 317L, and 904L offer good resistance in moderate chloride environments

- Susceptible to pitting and stress corrosion cracking in seawater

- Duplex and super duplex improve this but still not as resistant as titanium

Conclusion: Titanium clearly wins for long-term performance in aggressive media.

2. Mechanical Strength

| Property | Titanium Grade 2 | Stainless Steel 316L |

|---|---|---|

| Yield Strength (MPa) | ~275 | ~170 |

| Tensile Strength (MPa) | ~345 | ~485 |

| Elongation (%) | ~25–30 | ~35 |

| Density (g/cm³) | 4.5 | 7.9 |

- Titanium is lighter and more flexible, good for weight-sensitive applications (aerospace, marine)

- Stainless steel is stronger in tension, better for structural loads

Conclusion: Titanium is better where weight and flexibility matter. SS is stronger but heavier.

3. Thermal Conductivity

- Titanium Grade 2: ~16.3 W/m·K

- Stainless Steel 316L: ~14.6 W/m·K

Although close, titanium has slightly better thermal conductivity, which helps with efficient heat transfer in compact exchangers.

4. Cost Comparison

- Titanium tubes can cost 3 to 5 times more than standard stainless steel

- However, titanium often delivers 3–10× longer service life in harsh conditions

Conclusion: Higher upfront cost for titanium may be justified by lower lifecycle cost in corrosive settings.

5. Applications by Industry

| Industry | Preferred Material | Why |

|---|---|---|

| Desalination | Titanium | Resistant to seawater and biofouling |

| Chemical Processing | Depends on media | Titanium for acids, SS for low-chloride |

| Marine HVAC | Titanium or CuNi | Titanium preferred in deep-sea |

| Oil & Gas Offshore | Duplex / Super Duplex | Or titanium for long-term ROI |

| Power Generation | Stainless Steel | Cost-effective, wide availability |

For ASME, PED, or EN 13445 pressure systems, both materials can be qualified with the right documentation.

6. DLSS Product Scope

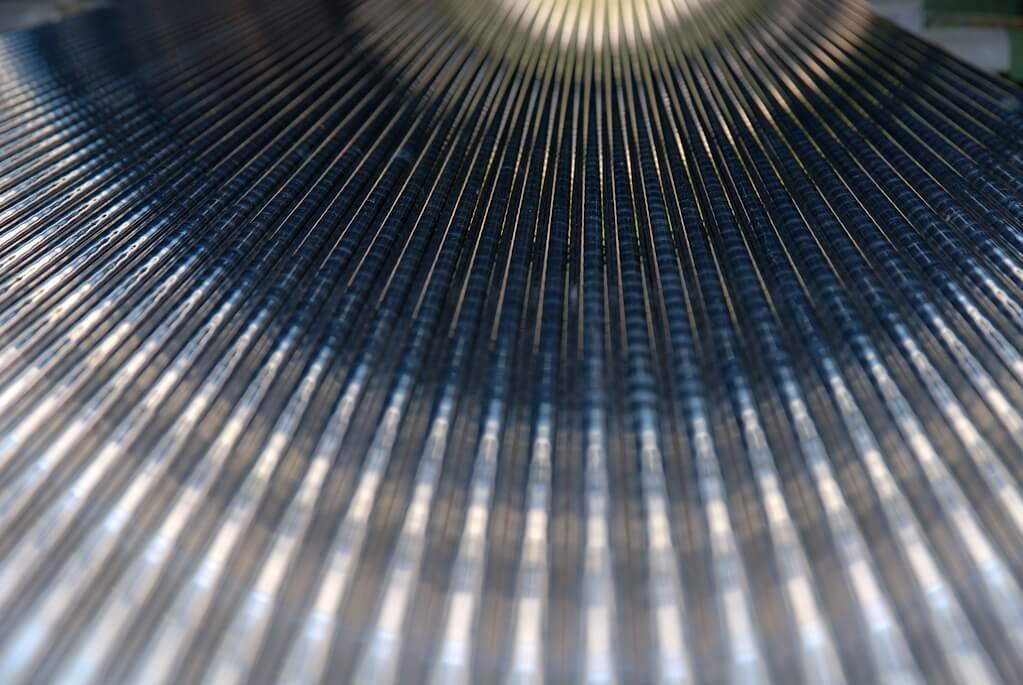

Titanium Tubes:

- Standards: ASTM B338, ASTM B861

- Grades: Titanium Gr.1 / Gr.2 / Gr.7

- Sizes: OD 6–38 mm, WT 0.5–3.0 mm

- Surface: Pickled, bright annealed, EP

- Tests: Hydro, PMI, UT, surface Ra test

Stainless Steel Tubes:

- Standards: ASTM A213 / A269 / A789

- Grades: 304L, 316L, 317L, 904L, 2205

- Surface: Polished, BA, EP

- Testing: ET, UT, Hydro, PMI, Grain size

FAQs

Q1: Can titanium be welded as easily as stainless steel?

Welding titanium requires more care—argon shielding is essential to prevent oxidation.

Q2: Are there any applications where stainless steel is better?

Yes—moderate conditions with low chlorides, structural applications, or when cost is the main constraint.

Q3: Is there a difference in tube longevity?

Yes. Titanium can last over 20–30 years in seawater. Stainless steel often requires replacement every 3–5 years in similar settings.

Conclusion

Both titanium and stainless steel are proven materials for heat exchanger tubes. Titanium is unmatched for corrosive media, seawater, and critical reliability, while stainless steel remains popular for general use due to availability and price.

DLSS offers both materials with full traceability, testing, and global supply capabilities.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help selecting the right tube material for your application? Our technical team is here to help you choose based on pressure, corrosion, and thermal needs.