Introduction

TP304 and TP316L are the two most widely used austenitic stainless steel grades in industrial piping, particularly in heat exchangers, boiler systems, and chemical plants. While both belong to the same stainless steel family, they differ in corrosion resistance, mechanical properties, and application suitability.

In this article, we compare TP304 and TP316L across 5 key aspects to help engineers, procurement teams, and project managers make informed material decisions.

1. Chemical Composition

| Element | TP304 (%) | TP316L (%) |

|---|---|---|

| C | ≤ 0.08 | ≤ 0.03 |

| Cr | 18.0–20.0 | 16.0–18.0 |

| Ni | 8.0–11.0 | 10.0–14.0 |

| Mo | — | 2.0–3.0 |

- TP316L contains molybdenum (Mo), which significantly enhances resistance to chloride-induced corrosion.

- The low carbon in TP316L prevents carbide precipitation during welding.

2. Corrosion Resistance

| Environment | TP304 | TP316L |

|---|---|---|

| General atmospheres | Suitable | Suitable |

| Mild acids (HNO₃, acetic acid) | Good | Excellent |

| Chloride-rich (marine, saltwater) | Limited | Strong resistance |

| Sulfate-based chemicals | Moderate | Preferred |

Reference: Outokumpu Stainless Handbook

Conclusion: TP316L is clearly the better choice in marine, chemical, and food-grade environments.

3. Weldability & Fabrication

| Property | TP304 | TP316L |

|---|---|---|

| Weldability | Excellent | Excellent |

| Post-weld corrosion risk | Possible | Low |

| Cold workability | Good | Good |

- TP316L’s low carbon makes it ideal for heavy-welded structures or sanitary piping.

- Both grades are suitable for cold drawing, bending, and forming.

4. Cost Comparison

| Grade | Market Price Estimate (USD/kg)* | Notes |

|---|---|---|

| TP304 | ~$2.5–3.0 | Most common and economical choice |

| TP316L | ~$3.2–3.8 | Higher nickel & molybdenum content |

*Prices vary by region and market trends.

Tip: TP316L may be 15–25% more expensive, but the long-term value in aggressive environments can be substantial.

5. Application Suitability

| Industry / Use Case | Preferred Grade |

|---|---|

| HVAC, water chillers | TP304 |

| General process piping | TP304 |

| Marine heat exchangers | TP316L |

| Pharmaceutical piping | TP316L |

| Food & beverage production | TP316L |

| Oil & gas refineries | TP316L |

DLSS commonly supplies TP316L to customers in South Korea, Malaysia, Iran, and Saudi Arabia for chemical and heat exchanger projects.

Conclusion

If your project is in a clean, non-corrosive environment, TP304 is a cost-effective and capable option.

If you’re dealing with chlorides, acids, or require welding, TP316L is the superior and safer choice.

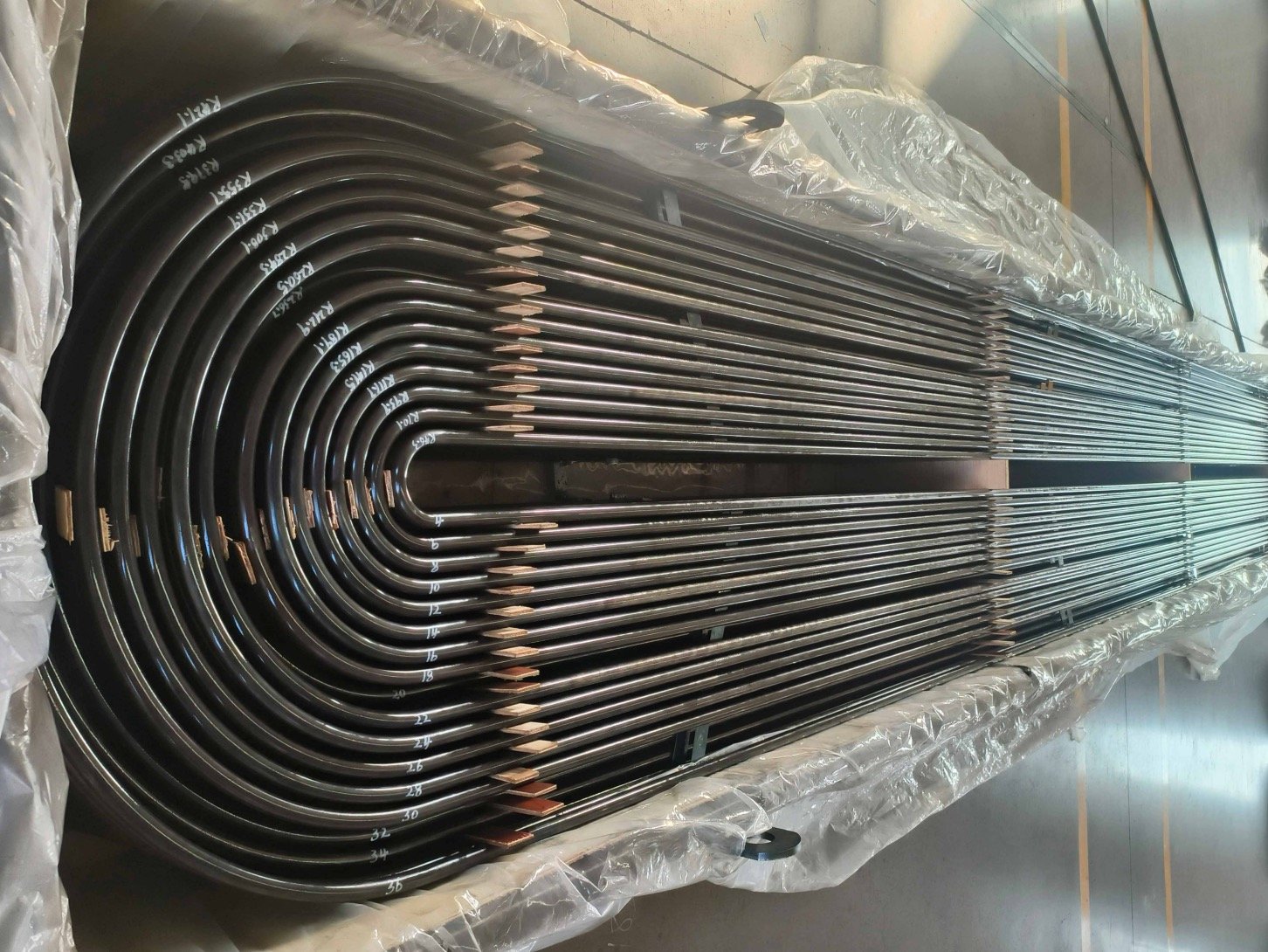

DLSS provides both TP304 and TP316L seamless tubes in compliance with ASTM A213 / A312, with bright annealed or pickled finish, and supports custom dimensions and U-bends.

Ready to Request a Quote?

Let our engineers help you select the right material for your next project.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com