Finned tubes come in a variety of designs, each engineered to meet specific heat transfer and operating conditions. Choosing the right type of finned tube is essential for achieving optimal heat exchanger efficiency and long-term durability.

If you are new to the concept, you can first read our article What is a Finned Tube and How It Improves Heat Exchanger Efficiency for an introduction.

1. High-Frequency Welded Finned Tubes

In this type, steel or alloy fins are helically wound around the tube and welded using high-frequency electric current. This method ensures:

- Strong metallurgical bond between fin and tube

- High thermal conductivity

- Long service life in high-temperature environments

Applications: Petrochemical plants, boilers, power plants.

2. Extruded Finned Tubes

Manufactured by extruding aluminum or copper over the base tube, producing a tight mechanical bond and excellent corrosion protection.

- Superior resistance to environmental corrosion

- Suitable for offshore and marine use

Applications: Seawater condensers, HVAC systems, desalination plants.

3. Spiral (Continuous) Finned Tubes

These tubes feature continuous helical fins wrapped around the tube’s outer surface.

- Increased heat transfer surface area

- Good for air-side heat exchange

Applications: Air-cooled heat exchangers, gas coolers, oil heaters.

4. Low-Fin Tubes

Fins are rolled directly into the outer surface of the tube wall, creating small, closely spaced fins.

- Compact size with moderate heat transfer enhancement

- Improved resistance to fouling

Applications: Refrigeration, chillers, chemical processing.

5. Serrated Finned Tubes

Fins are cut into segments (serrations) to create turbulence in the air stream, improving heat transfer.

- Higher heat transfer rates compared to smooth fins

Applications: Gas-to-air heat exchangers, industrial dryers.

Choosing the Right Finned Tube

When selecting a finned tube, consider:

- Operating Temperature – Choose materials that withstand your process conditions.

- Corrosion Resistance – Select alloys resistant to the fluids and environment.

- Heat Transfer Requirements – Match fin design to your required efficiency.

For guidance on improving performance, see our guide on Heat Exchanger Maintenance Checklist.

Conclusion

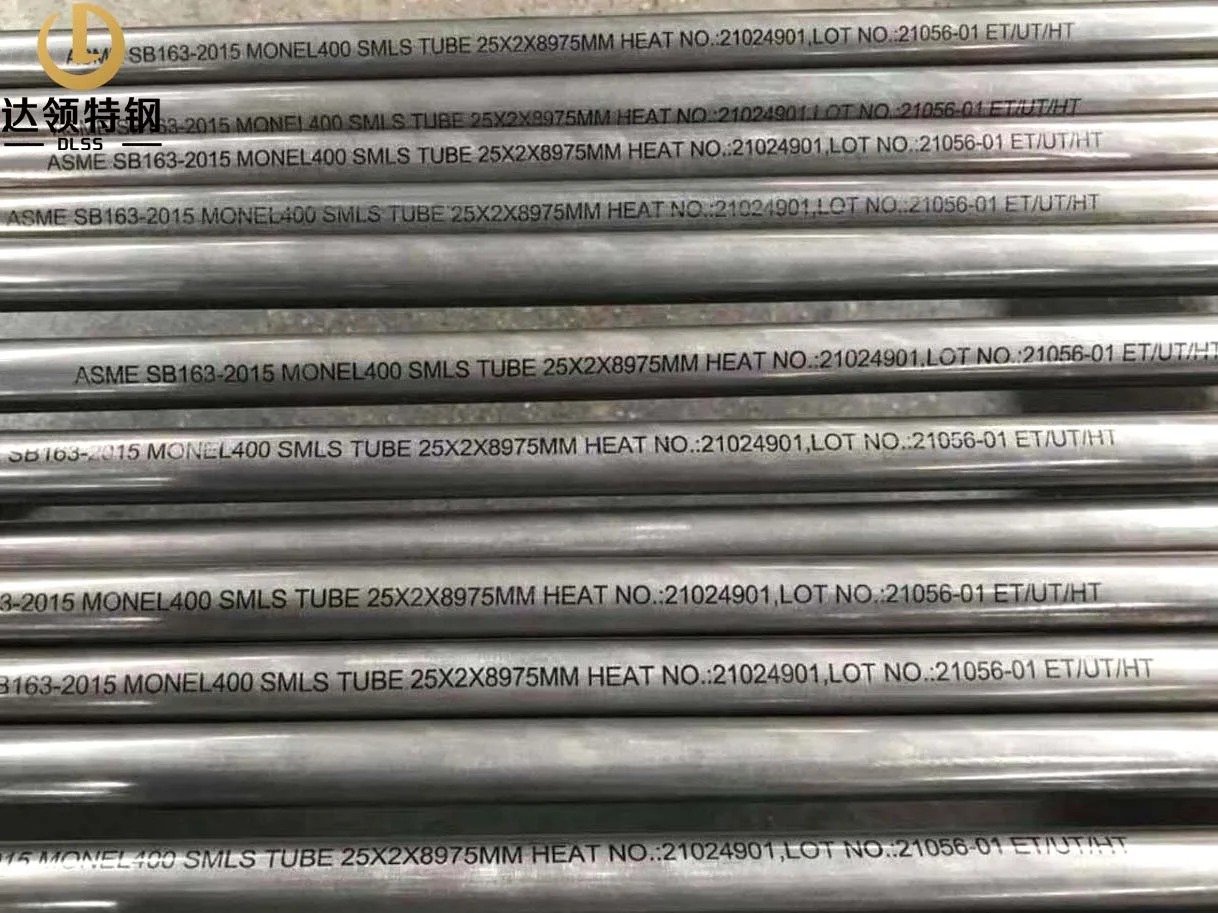

Each type of finned tube offers distinct advantages. The right choice depends on your application, process conditions, and desired efficiency. At DLSS, we provide customized finned tube manufacturing, from material selection to precise engineering, ensuring maximum heat exchanger performance.

Contact our engineering team today at www.dlsspipeline.com or email info@dlsspipe.com to discuss the best finned tube for your project.