Meta Description:

Explore how U-bent stainless steel tubes optimize space, thermal transfer, and maintenance efficiency in power plants and chemical facilities across South America.

Introduction

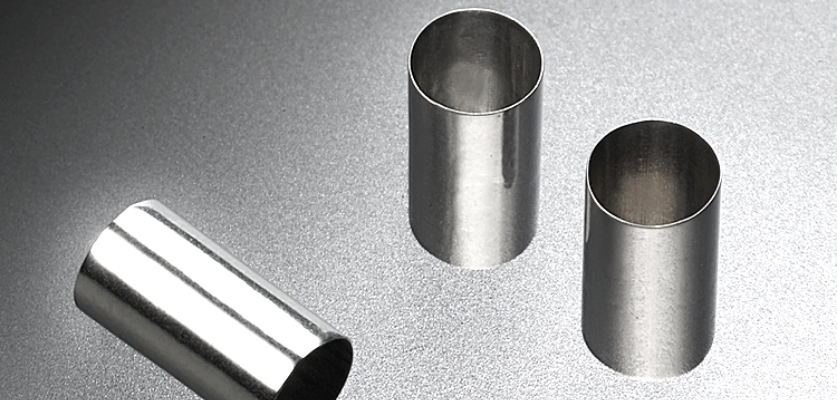

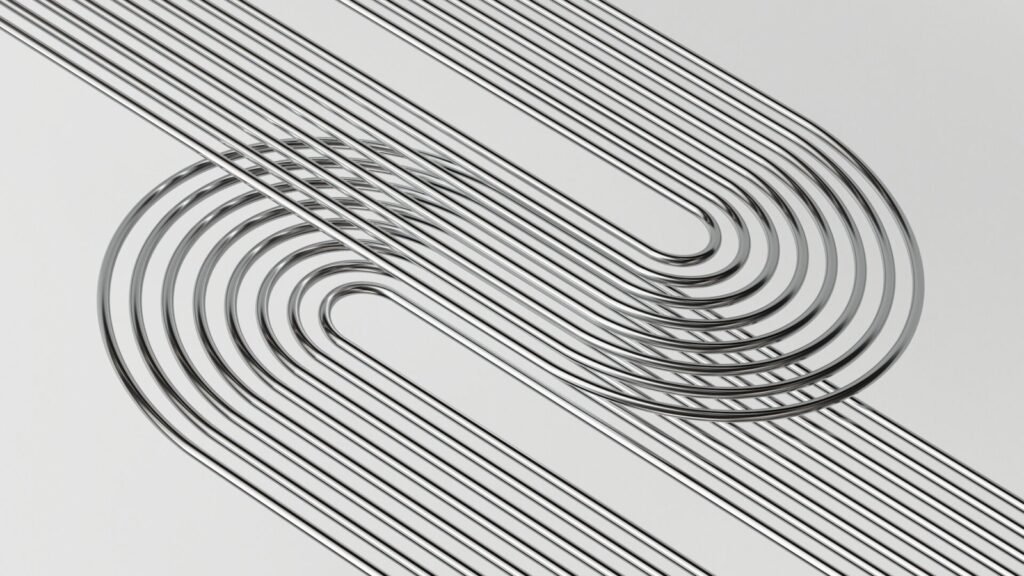

In complex thermal systems—such as boilers, condensers, and heat recovery units—U-bent stainless steel tubes offer a compact, efficient, and high-performance solution. Their curved design allows for greater heat transfer in limited space, with minimal pressure loss and easier maintenance access.

These tubes are particularly valuable in South American energy projects, where climate, terrain, and installation space pose design constraints.

Why U-Bent Tubes Are Essential

- Space-saving configuration for horizontal or vertical mounting

- Simplified header layout in shell & tube exchangers

- Reduced welding points → fewer potential leak sites

- Excellent mechanical strength under thermal cycling

- Ideal for counterflow or parallel flow heat transfer systems

Used extensively in:

- Steam boilers

- HRSG units in gas turbines

- Feedwater heaters

- Refinery condensers

- Nuclear auxiliary systems

Tube Materials and Specifications

| Material | Properties | Standards | Application Focus |

|---|---|---|---|

| TP316L | Corrosion resistance, common for steam applications | ASTM A213 / EN 10216-5 | Power generation, refineries |

| TP321/347 | High-temperature stability with carbide resistance | ASTM A213, SA213, ISO 1127 | Superheated zones, fossil plants |

| TP304/304L | Cost-effective and versatile | ASTM A213, ASME B36.10 | Low-pressure, utility heating |

| Duplex S31803 | Higher strength + chloride pitting resistance | ASTM A789 / A790 | Offshore condensers, gas processing |

| TP316Ti | Elevated chloride and oxidation resistance | EN 10217-7 / ASTM A249 | Pulp plants, geothermal facilities |

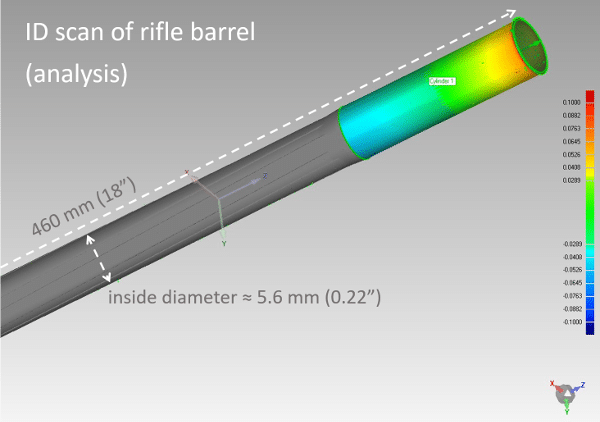

Tubes are typically bent to radius 1.5×OD to 2.0×OD, with minimal thinning or ovality.

DLSS U-Bending Capabilities

- Tube OD range: 12.7 mm – 38.1 mm

- Bending Radius: 1.5D, 1.8D, 2.0D (custom on request)

- Wall thinning tolerance: ≤ 12.5%

- Post-bend heat treatment: Solution annealing or stress-relief

- Surface finishes: Pickled, Bright Annealed, EP

- Inspection: Hydro test, UT, visual check on bend zone

- Marking: Directional flow arrows and tube ID codes

- Certifications: ASTM A213, EN 10204 3.1, TPI available

Related reference: Nickel Institute – Heat Transfer Alloys

Case Study: Argentina Power Utility Retrofit

In 2023, DLSS supplied over 9,000 U-bent TP347H tubes to a thermal retrofit project in northern Argentina. The installation reduced space requirements by 20% and improved heat transfer efficiency by 11%, confirmed by in-situ thermal testing.

Frequently Asked Questions (FAQs)

Q: Can DLSS tubes be delivered pre-bent and pre-tested?

Yes. All U-bent tubes are supplied ready for installation with MTCs and NDT reports.

Q: How do you ensure wall thickness uniformity in bends?

We use calibrated bending dies, perform bend thinning checks, and offer hydro or UT inspection on request.

Q: What is your lead time to South America?

Standard delivery is 25–35 days to Brazil, Argentina, or Chile, depending on port and quantity.

Conclusion

DLSS U-bent tubes are engineered for performance where space, pressure, and reliability matter most. With a proven track record in Latin American industries, we deliver fully certified, high-precision solutions—ensuring your systems run safer, longer, and more efficiently.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com