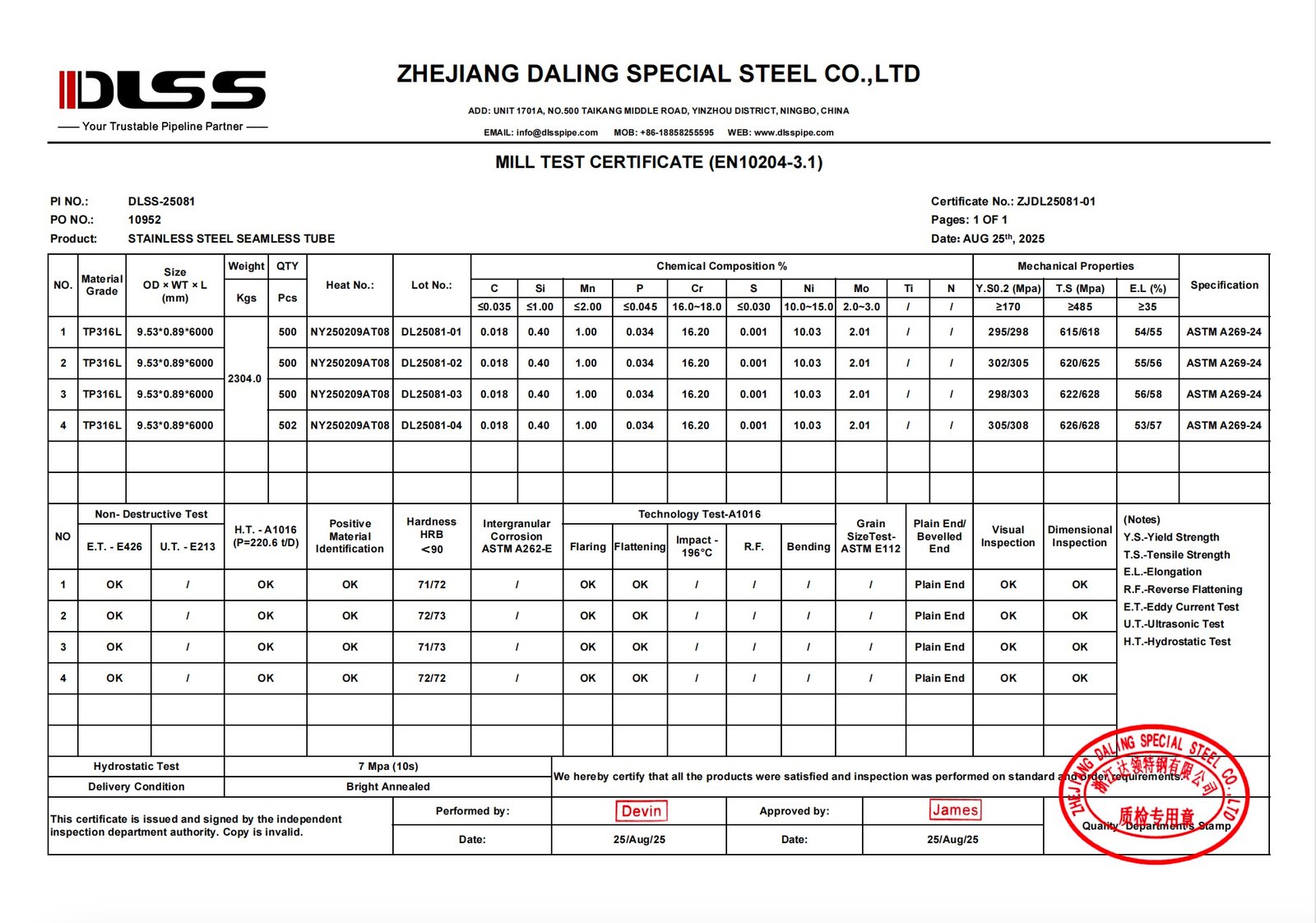

Choosing between welded and seamless tubes can impact your heat exchanger’s performance, durability, and cost. While both have their place, understanding their differences helps engineers and purchasers make informed decisions. In this blog, we compare these two types of stainless steel tubes and highlight where each one excels.

1. Manufacturing Process

- Welded tubes: Formed by rolling stainless steel strips and welding the seam.

- Seamless tubes: Made by piercing a solid billet and drawing it into shape—no weld seam.

This difference affects the structural integrity and mechanical properties of the tube.

2. Mechanical Strength

Seamless tubes generally offer:

- Higher strength under pressure

- Better resistance to fatigue and cracking

- No weak points along a welded seam

In high-pressure boilers and heat exchangers, seamless tubes are often the safer choice.

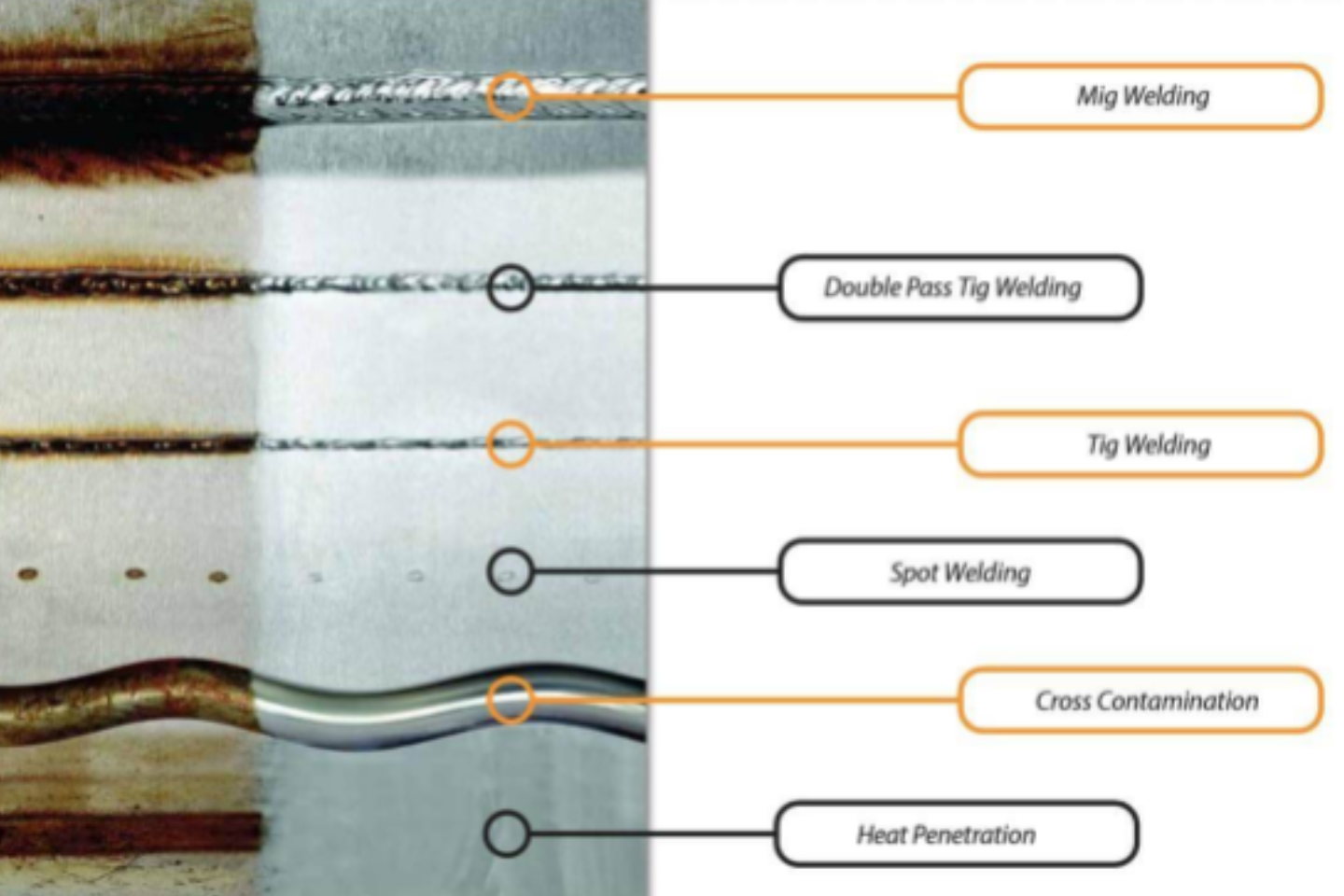

3. Corrosion Risk

The weld seam in welded tubes may:

- Be more susceptible to corrosion

- Contain microstructural irregularities

- Need additional processing (like annealing or pickling)

Seamless tubes, especially those from DLSS, have a smooth, uniform structure with minimal risk of localized corrosion.

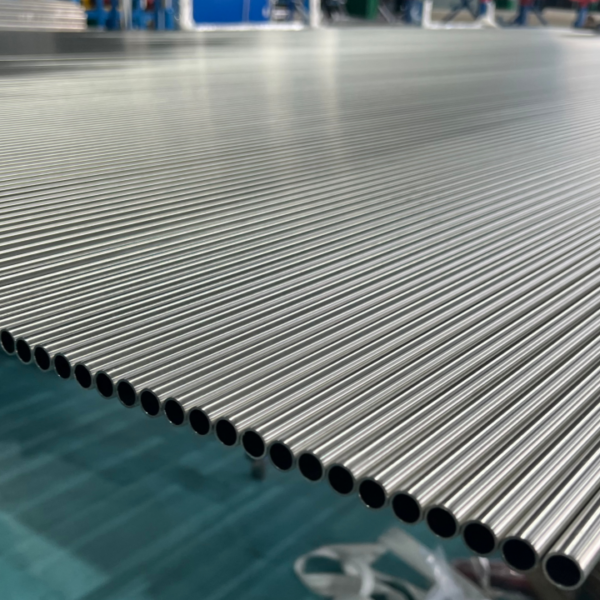

4. Dimensional Accuracy & Surface Finish

Welded tubes may have:

- Greater ovality

- Visible seam marks

- Slightly less consistent wall thickness

DLSS seamless tubes are known for:

- Tight dimensional tolerance

- Clean, pickled surface finish

- Precision straightness

5. Application Suitability

- Use welded tubes for low-pressure, non-critical applications where cost is a concern.

- Choose seamless tubes for demanding industrial systems, high temperatures, and corrosive environments.

Conclusion

For many heat exchanger applications, seamless stainless steel tubes offer better strength, consistency, and reliability. DLSS specializes in high-precision seamless tubes designed to meet the most demanding industrial standards.

Why Choose DLSS as Your Stainless Steel Tube Partner?

With over 30 years of experience and exports to 40+ countries, DLSS offers:

- Customized tube solutions for heat exchangers and condensers

- Full compliance with ASTM/ASME standards

- Third-party inspections and full quality reports

- Precision production, fast delivery

Contact us today to get a free consultation or quote: info@dlsspipe.com