Meta Description:

Learn the difference between pickling and passivation for stainless steel tubes. Understand how these surface treatments improve corrosion resistance and comply with industry standards like ASTM A380 and A967.

Introduction

Stainless steel may be known for its corrosion resistance, but improper surface conditions can compromise performance. To ensure maximum durability, two essential surface treatments are often used: pickling and passivation.

These processes are vital for removing contamination, enhancing corrosion resistance, and meeting industry specifications—especially in applications like food processing, pharmaceuticals, marine, and chemical industries.

1. What is Pickling?

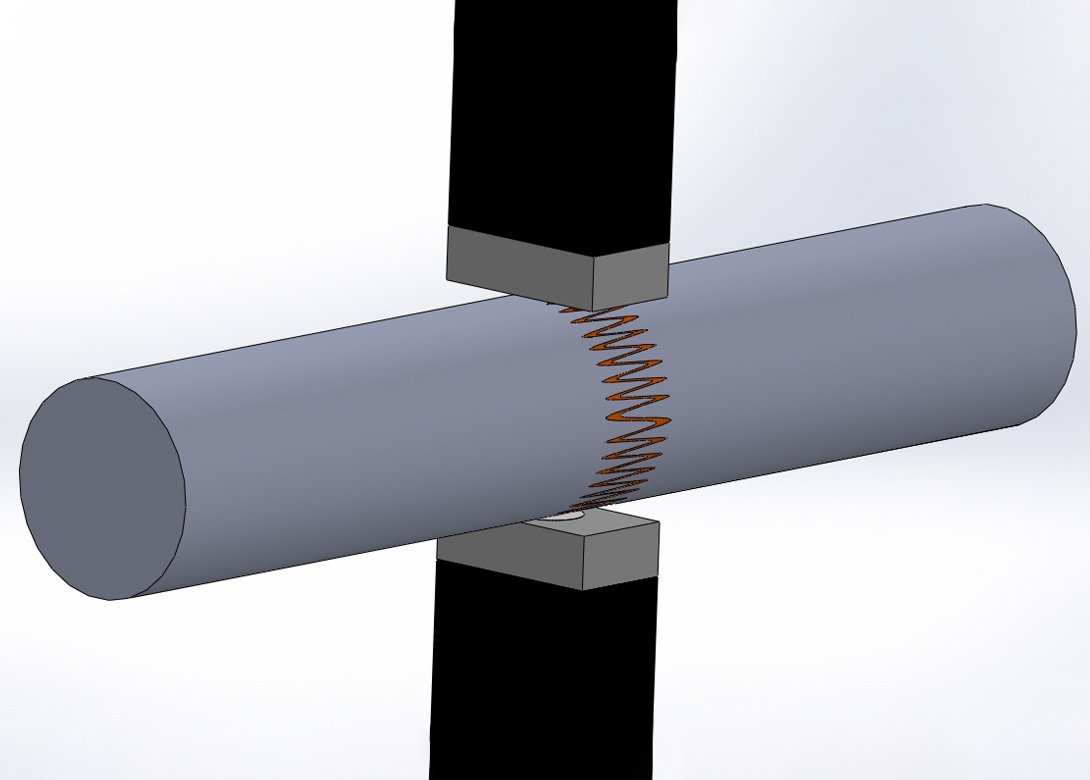

Pickling is a chemical treatment that removes oxides, heat tint, weld scale, and impurities from the surface of stainless steel after manufacturing processes like welding or annealing.

How It Works:

- Involves nitric acid + hydrofluoric acid or commercial pickling pastes

- Removes surface impurities and exposes clean, active stainless surface

When It’s Used:

- After welding or heat treatment

- For removing black scale or discoloration

- Before passivation or electropolishing

Learn more: ASTM A380 – Cleaning & Descaling of Stainless Steel Parts

2. What is Passivation?

Passivation is the process of forming a thin, uniform oxide layer (chromium oxide) on stainless steel to restore or enhance corrosion resistance.

How It Works:

- Involves immersion in nitric acid or citric acid solutions

- Removes free iron and contaminants that can cause rust

- Allows chromium-rich passive layer to regenerate

When It’s Used:

- After pickling or mechanical cleaning

- On machined or handled stainless parts

- For critical hygiene or medical applications

Related standard: ASTM A967 – Chemical Passivation Treatments for Stainless Steel

3. Pickling vs. Passivation – Key Differences

| Feature | Pickling | Passivation |

|---|---|---|

| Function | Removes scale and oxides | Restores protective oxide layer |

| Chemicals Used | HNO₃ + HF | HNO₃ or citric acid |

| Surface Appearance | Matte / etched | Smooth, original finish |

| Surface Roughness | Slightly increases Ra | No impact on Ra |

| Use Before/After Welding | Required after heat-tint or welds | Optional final step |

4. DLSS Pickling & Passivation Capabilities

At DLSS, all stainless steel seamless tubes undergo controlled pickling and optional passivation, ensuring:

- Removal of oxides, scaling, and contaminants

- Full compliance with ASTM A380 / A967

- Surface finish suited for high-purity and industrial applications

- Custom treatments upon customer specification

Available Services:

| Process | Availability |

|---|---|

| Internal Pickling | Yes (for tubes ≥10mm ID) |

| External Pickling | Yes |

| Full Immersion | On request |

| Passivation Only | Yes (for polished/EP tubes) |

| Certification | Yes, with MTC and photos |

5. Applications That Require Pickling/Passivation

| Industry | Requirement |

|---|---|

| Food & Beverage | Clean, oxide-free interior surfaces |

| Pharmaceuticals | Biofilm-resistant tube interiors |

| Oil & Gas | Corrosion resistance for sour service lines |

| Water Treatment | Prevent contamination or iron leaching |

| Power Plants | Scale-free boiler tubes |

For guidance, refer to Outokumpu Surface Finishes Handbook

FAQs

Q1: Is passivation mandatory after pickling?

Not always. If a strong passive layer reforms naturally, additional passivation may not be needed. However, in critical applications (e.g., WFI, semiconductors), both are recommended.

Q2: Will pickling change the tube dimensions?

No significant change occurs unless pickling is overly aggressive or prolonged. DLSS controls time and acid concentration precisely.

Q3: Are there environmental concerns?

Yes. Pickling involves hazardous acids. DLSS treats all waste according to national environmental standards and safety protocols.

Q4: Can DLSS supply pickled and passivated tubes with export documentation?

Yes. All surface treatments are documented with photos, batch records, and noted in the EN 10204 3.1/3.2 MTC.

Conclusion

Proper surface treatment is a cornerstone of stainless steel tube performance. At DLSS, we ensure every tube undergoes reliable pickling and passivation processes to deliver clean, corrosion-resistant, and standard-compliant products to clients worldwide.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need pickled and passivated stainless steel tubes for a critical project? DLSS can help with expert advice, inspection-ready documents, and precision-finished products.