Meta Description:

Grain size in stainless steel tubes directly affects corrosion resistance, mechanical strength, and heat exchanger durability. Learn how ASTM grain size ratings influence performance and certification.

Introduction

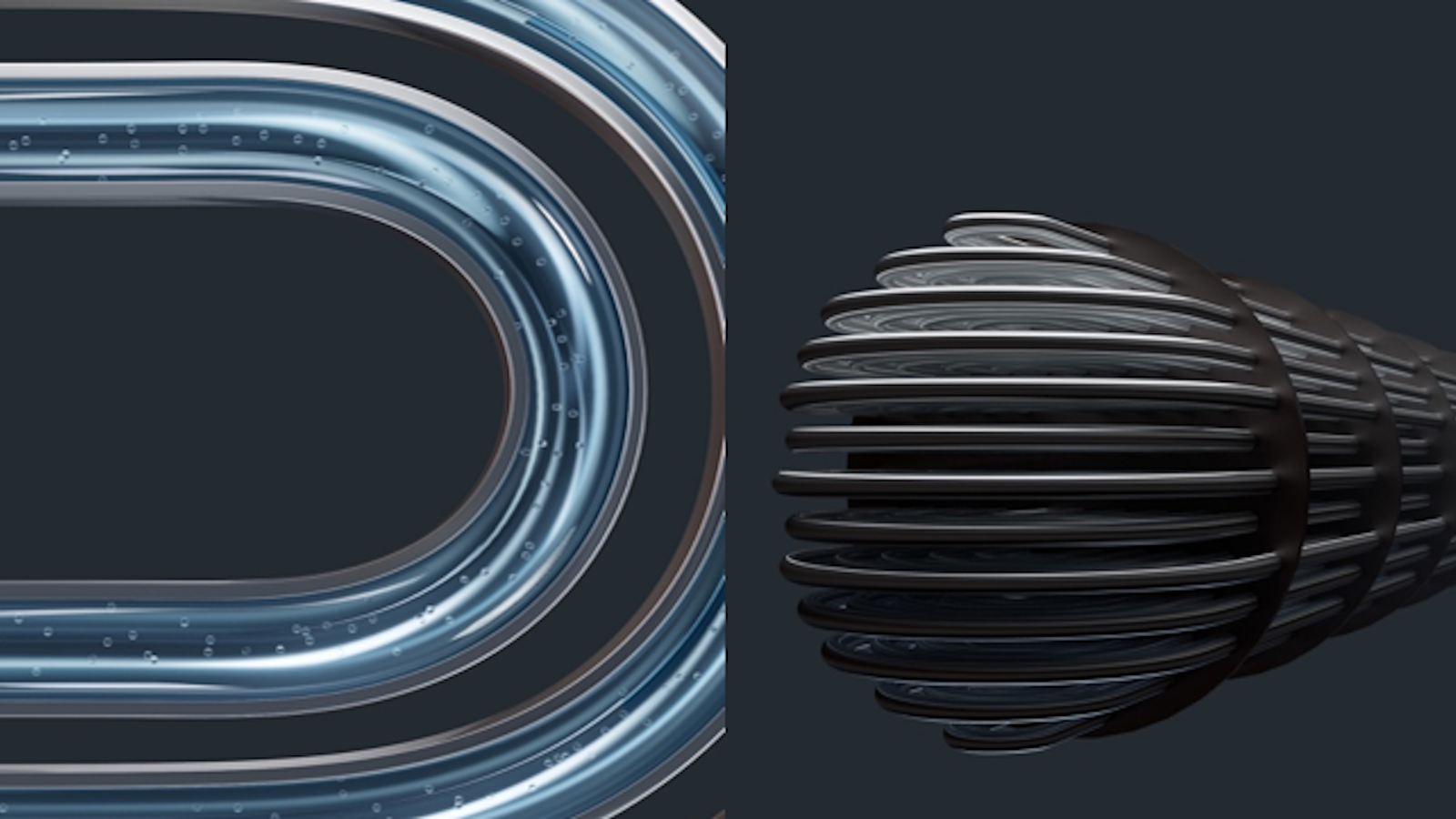

When engineers specify stainless steel tubes for shell-and-tube heat exchangers, attention is often paid to chemical composition, wall thickness, and surface finish. But there’s another hidden factor that critically affects long-term performance: grain size.

Whether you’re sourcing TP316L, TP321, or Duplex tubes, understanding grain size ensures you meet both mechanical strength and corrosion resistance requirements, especially in high-temperature and high-pressure environments.

What Is Grain Size in Stainless Steel?

Grain size refers to the average diameter of the individual crystalline grains in a metal’s microstructure. It is typically measured per ASTM E112, and is reported as a grain number:

- Larger grain number = finer grain size

- Smaller grain number = coarser grain

For example:

| ASTM Grain Number | Approx. Grain Diameter (μm) | Description |

|---|---|---|

| 3 | ~125 | Very coarse |

| 5 | ~65 | Acceptable in general use |

| 7 | ~32 | Fine grain |

| ≥8 | ~22 or less | Ultra-fine, common in 316L BA tubes |

Reference: ASTM E112 – Standard Test Methods for Determining Average Grain Size

Why Does Grain Size Matter in Heat Exchanger Tubes?

1. Corrosion Resistance

Finer grain size enhances intergranular corrosion resistance, especially after welding or bending. This is critical in:

- Seawater applications (e.g., Duplex, 254 SMO)

- Acidic media in chemical reactors

- Steam generation in power boilers

Larger grains can act as initiation sites for pitting or SCC (stress corrosion cracking).

2. Mechanical Strength and Fatigue Life

Fine grains improve:

- Yield strength

- Tensile strength

- Fatigue resistance in cyclic thermal conditions

In U-bend tubes or high-vibration environments, finer grains minimize crack propagation.

3. Heat Treatment Responsiveness

Alloys like TP347H or TP321 benefit from controlled grain growth during solution annealing. If grain size is not optimized, the material may become brittle or fail creep resistance tests, particularly above 600°C.

Industry Standards That Require Grain Size Control

- ASTM A213 / A269 / A789: Often specify ASTM Grain Size ≥ 5 or ≥ 6

- NACE MR0175 / ISO 15156: Implies control for SSC resistance

- PED / AD2000-W10: Require documented grain size for pressure vessel tubes

- TP347HFG: A special grade with “HFG” meaning High Fineness Grain for ultra-long service

How Is Grain Size Tested?

At DLSS, we perform grain size measurement via:

- Metallographic examination under microscope (ASTM E112)

- Etching and cross-sectional polishing

- Certified by third-party labs (SGS, BV) upon request

Each tested tube heat can be linked to its EN 10204 3.1 / 3.2 MTC, with grain size clearly marked.

Real-World Example: 316L U-Bend Tube in a Refinery

A client in Turkey installed ASTM A213 TP316L U-bend tubes in a heat exchanger operating with hot seawater. Due to improper heat treatment at the supplier’s end, grain size averaged ASTM No. 3–4, resulting in:

- Localized wall thinning

- Intergranular attack

- Partial bundle replacement within 18 months

DLSS replaced the bundle with tubes heat-treated to achieve ASTM Grain No. ≥7, and the problem has not recurred since.

How DLSS Ensures Grain Size Compliance

We deliver:

- Controlled annealing processes (1050–1150°C)

- Rapid quenching to freeze fine grain structure

- Grain size reports as part of QA documentation

- Tubes suitable for sour service, high-temp systems, and EPC acceptance

Conclusion

Grain size may not be visible, but its impact on stainless steel tube performance is enormous. It affects corrosion resistance, strength, weldability, and long-term reliability of heat exchangers.

Always verify grain size requirements when ordering tubes for:

- Power boilers

- Chemical plants

- Oil & gas platforms

- Seawater cooling systems

DLSS offers precision-engineered stainless steel tubes with documented microstructure control for global industrial applications.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for tubes with guaranteed fine grain structure and full QA certification? Contact us today for consultation and quotes.