1. Overview

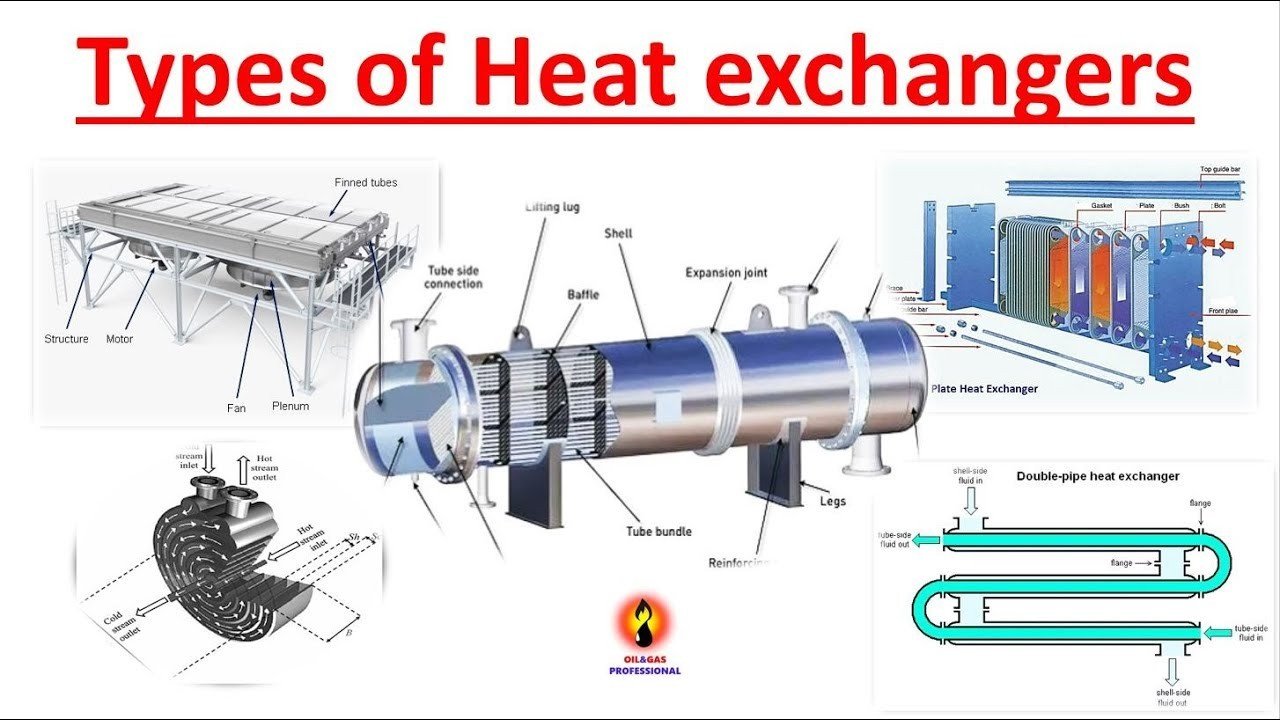

In demanding industries such as heat exchangers, condensers, boilers, and pressure vessels, stainless steels of the 316 family are among the most widely used materials. However, choosing between 316, 316L, and 316Ti depends on factors like weldability, temperature stability, and corrosion resistance.

At DLSS (Zhejiang Daling Special Steel Co., Ltd.), we supply all three grades in seamless and welded tubes, manufactured under ASTM A213 / A312 / EN10216-5 with EN10204 3.1 / 3.2 certification. Our materials are trusted in more than 40 countries for critical heat exchanger and boiler applications.

2. Chemical Composition Comparison

| Grade | C (max %) | Mo (%) | Ti (%) | Typical Standard | UNS | EN No. |

|---|---|---|---|---|---|---|

| 316 | 0.08 | 2.0–2.5 | — | ASTM A312 / EN 1.4401 | S31600 | 1.4401 |

| 316L | 0.03 | 2.0–2.5 | — | ASTM A312 / EN 1.4404 | S31603 | 1.4404 |

| 316Ti | 0.08 | 2.0–2.5 | 5×C to 0.7 | EN 10216-5 / DIN 1.4571 | S31635 | 1.4571 |

Key difference:

- 316L has low carbon, minimizing carbide precipitation during welding.

- 316Ti contains titanium for stabilization, preventing sensitization at high temperatures.

3. Corrosion Resistance

- 316 / 316L: Excellent resistance to chloride and acidic media. Ideal for seawater-cooled heat exchangers and chemical processing.

- 316Ti: Titanium-stabilized, offering stronger resistance to intergranular corrosion when exposed to 450–850 °C for extended periods.

DLSS Engineering Note:

For welded tube bundles and pressure shells operating under moderate temperatures, 316L is often the best choice. For continuous operation above 500 °C, or cyclic heating in boilers, 316Ti ensures longer service life.

4. Weldability and Fabrication

- 316L offers excellent weldability and does not require post-weld heat treatment.

- 316Ti, though slightly more complex to weld, can be joined successfully using ER316Ti filler wire and controlled heat input.

- 316 is acceptable when welding is limited and the service temperature remains below 425 °C.

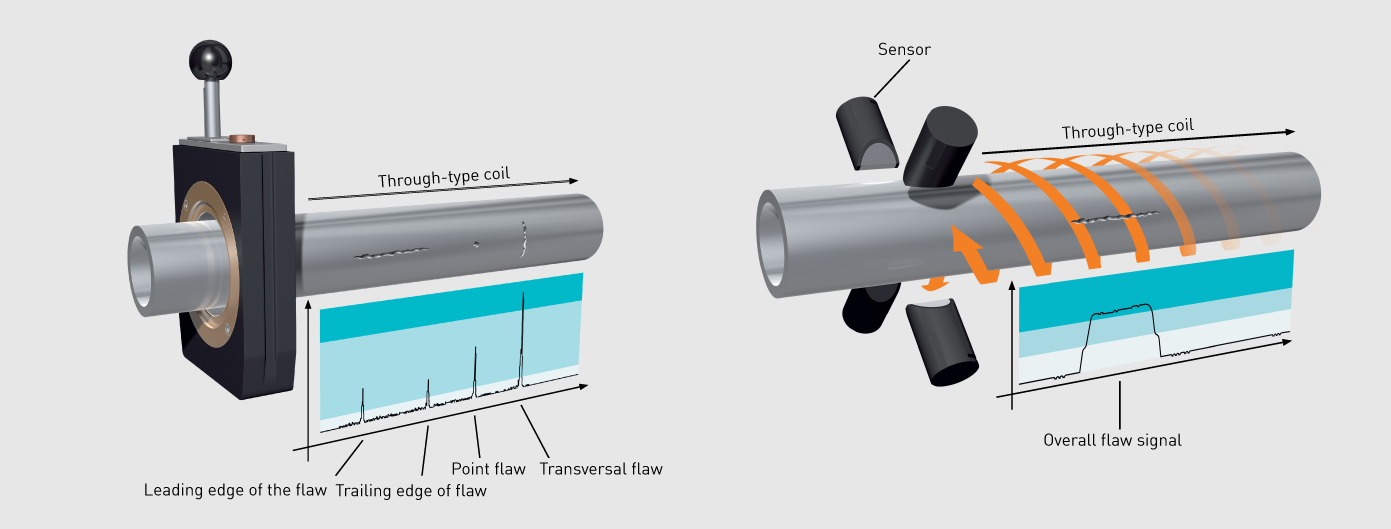

DLSS ensures 100% NDT inspection—including hydrostatic, eddy current, and ultrasonic tests—to guarantee weld integrity and defect-free structure.

5. High-Temperature Performance

| Grade | Continuous Service Temp (°C) | Resistance to Sensitization | Typical Use |

|---|---|---|---|

| 316L | ≤ 425 | Excellent | Heat exchangers, condensers |

| 316Ti | ≤ 600 | Superior | Boilers, reheaters, superheaters |

| 316 | ≤ 425 | Moderate | General piping systems |

The titanium addition in 316Ti prevents chromium carbide formation along grain boundaries, maintaining mechanical strength and corrosion resistance in the sensitization range.

6. Typical Industrial Applications

| Application | Recommended Grade | Reason |

|---|---|---|

| Heat Exchangers (Seawater Service) | 316L | High chloride resistance |

| Boiler Tubes & Superheaters | 316Ti | Long-term thermal stability |

| Condensers / Evaporators | 316L / 316 | Cost-effective corrosion protection |

| Food & Beverage Equipment | 316L | Easy polishing and hygienic surface |

| Chemical Reactors / Fertilizer Plants | 316Ti | Protection from sensitization & acid corrosion |

7. DLSS Manufacturing Excellence

With over 30 years of production experience, DLSS is a global supplier of stainless steel tubes, fittings, and flanges for heat exchanger and boiler applications.

Our strengths include:

- Full compliance with PED, AD2000, DNV, BV, ABS, LR, NK, CCS.

- Pickled, bright-annealed, and electro-polished surfaces for precision and cleanliness.

- U-tubes, low-finned tubes, and tube bundles custom-manufactured per drawing.

- Export packaging compliant with ISPM-15 standards for global shipments.

Visit www.dlsspipeline.com to explore our stainless steel solutions for heat exchanger and boiler systems.

8. Conclusion

| Condition | Best Choice |

|---|---|

| Frequent welding or chloride environment | 316L |

| Long-term high temperature (450–600 °C) | 316Ti |

| Balanced performance & cost efficiency | 316 |

DLSS Recommendation:

For most welded heat exchanger systems, 316L offers optimal weld integrity and corrosion resistance. For continuous high-temperature operation, 316Ti ensures reliable performance against sensitization and scaling.

9. FAQ

Q1: Can 316L completely replace 316Ti?

A: Not always. 316L performs better in welding but may not withstand prolonged high temperatures where sensitization occurs.

Q2: Is 316L stronger than 316?

A: The mechanical strength is similar; the key difference lies in carbon content and weldability.

Q3: Does DLSS supply 1.4571 (316Ti) tubes with heat treatment certificates?

A: Yes. DLSS provides full traceability and delivers each batch with solution annealing, PMI reports, and EN 10204 3.1 / 3.2 certificates.