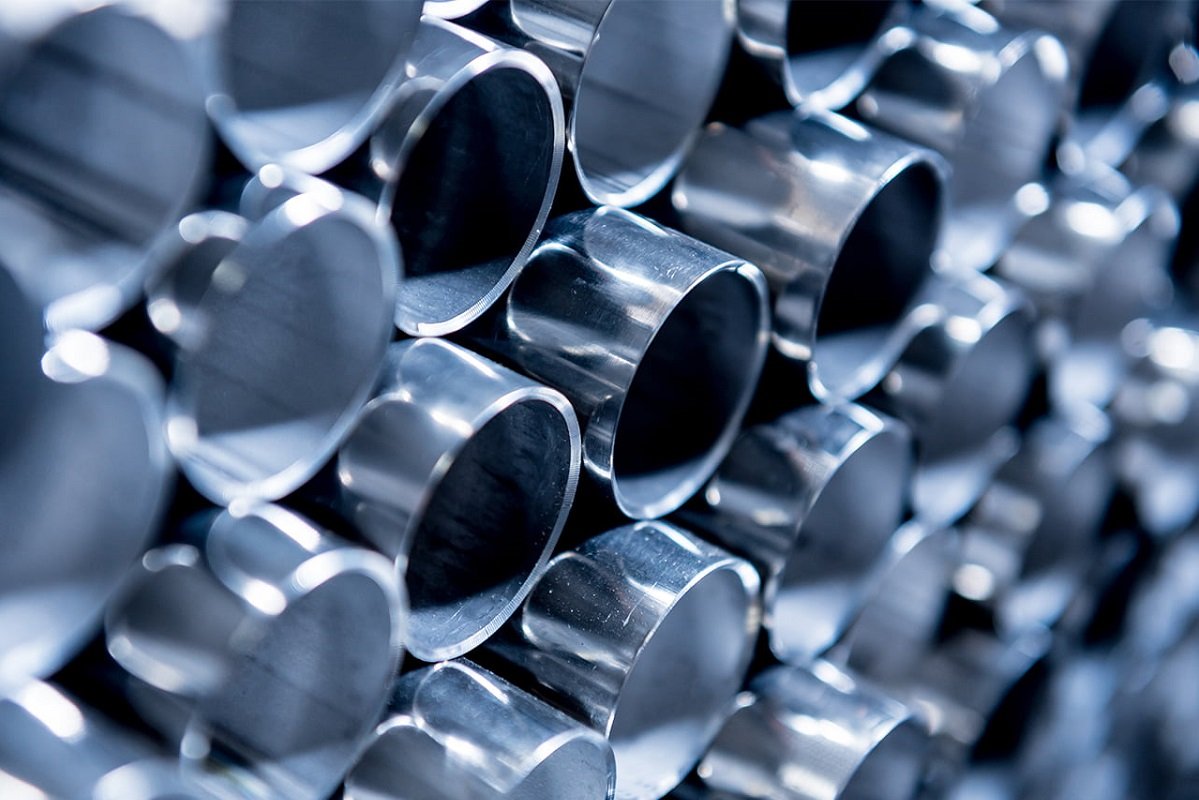

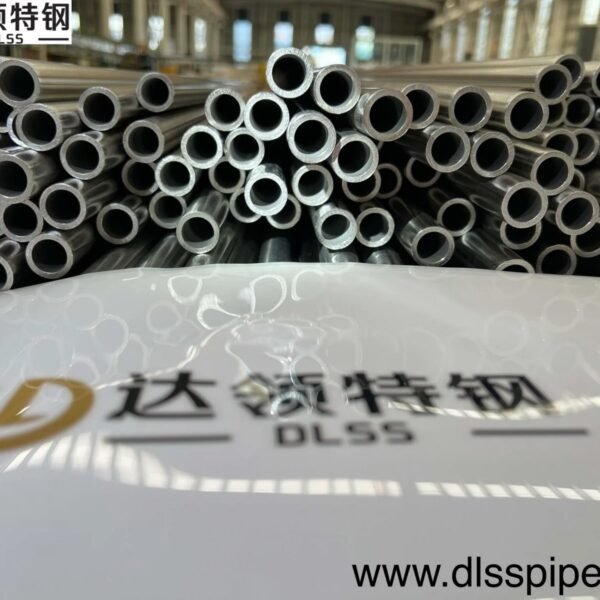

Product Overview: ASTM A789 S32750 Super Duplex Seamless Tube (19×2.4mm, BA Surface)

ASTM A789 S32750 seamless tubes are manufactured from super duplex stainless steel, known for its exceptional strength and corrosion resistance. This material is designed to perform in aggressive environments where standard austenitic or duplex grades would fail — such as in seawater, chemical processing, oil & gas, and heat exchanger systems.

With a 19mm OD, 2.4mm wall thickness, and a Bright Annealed (BA) surface, this tube is ideal for applications requiring clean inner surfaces, mechanical durability, and long service life.

Key Specifications

- Standard: ASTM A789 / ASME SA789

- Grade: S32750 (UNS S32750, also known as 1.4410, Super Duplex)

- Outer Diameter: 19 mm

- Wall Thickness: 2.4 mm

- Manufacturing Method: Seamless

- Surface Finish: Bright Annealed (BA) — clean, smooth, and oxidation-free

- Condition: Solution annealed and pickled, or bright annealed

- Length: Custom cut length available based on client needs

Chemical Composition (Typical S32750)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 24.0–26.0 |

| Nickel (Ni) | 6.0–8.0 |

| Molybdenum (Mo) | 3.0–5.0 |

| Nitrogen (N) | 0.24–0.32 |

| Manganese (Mn) | ≤ 1.20 |

| Carbon (C) | ≤ 0.03 |

| Silicon (Si) | ≤ 0.80 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.02 |

| Iron (Fe) | Balance |

The balanced dual-phase (ferritic–austenitic) structure of S32750 provides both high strength and excellent stress corrosion cracking (SCC) resistance, especially in chloride-rich environments.

Mechanical Properties

- Tensile Strength: ≥ 800 MPa

- Yield Strength (0.2% offset): ≥ 550 MPa

- Elongation: ≥ 15%

- Hardness: ≤ 32 HRC

These values make S32750 much stronger than standard 316L or even duplex 2205 tubing, with nearly double the yield strength.

Applications of ASTM A789 S32750 Seamless Tubes

This tubing grade is widely chosen for critical service environments where both high mechanical strength and corrosion resistance are required:

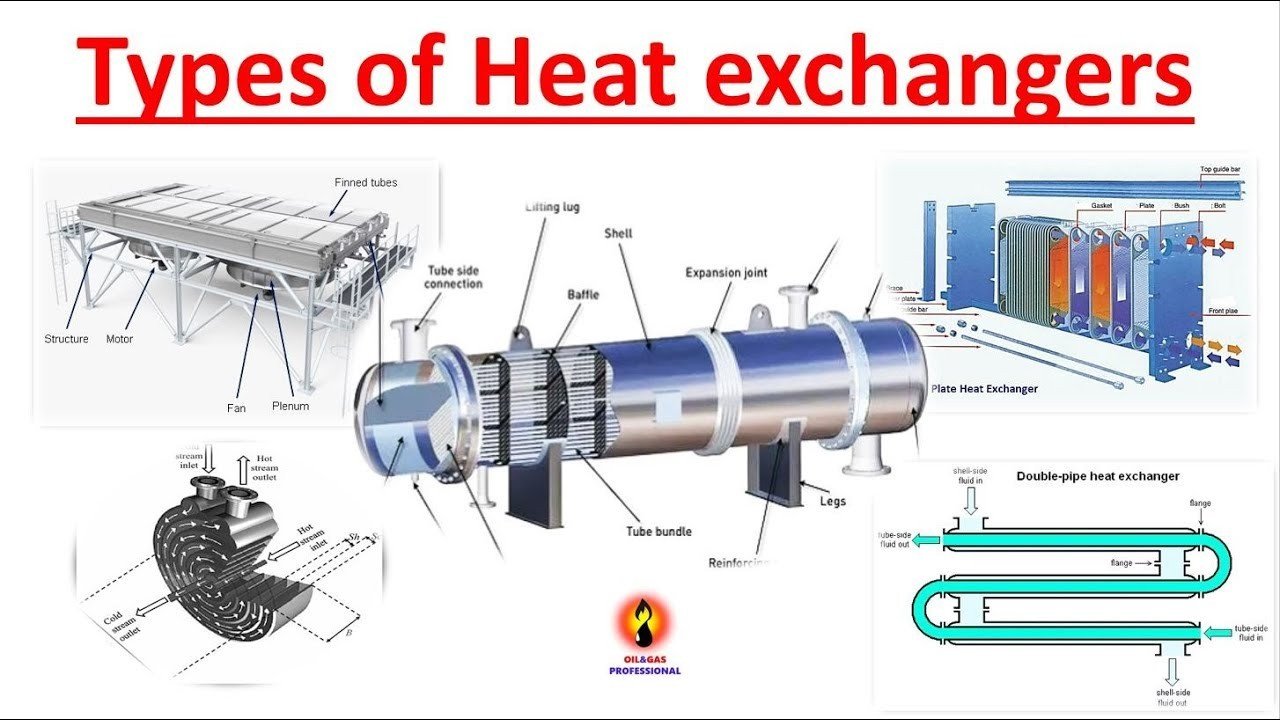

1. Heat Exchangers

S32750 seamless tubes are ideal for high-efficiency heat exchangers in refineries, power plants, and chemical processing units. The BA surface ensures low fouling and easy cleaning.

2. Seawater Systems

Excellent resistance to pitting, crevice corrosion, and chloride stress corrosion cracking makes these tubes perfect for seawater coolers, desalination plants, and marine exhaust systems.

3. Oil & Gas Industry

Used in offshore platforms, subsea equipment, and sour gas pipelines where high pressure and aggressive media are common.

4. Chemical Processing

Resists corrosion from acids (including nitric, sulfuric, and phosphoric), making it suitable for handling aggressive chemical fluids.

5. Pulp and Paper Industry

Performs well in bleach plants and digesters due to strong resistance against oxidizing and chlorinated environments.

Advantages of Bright Annealed (BA) Surface

The Bright Annealed finish is a key feature for industries demanding:

- Hygienic cleanliness (pharmaceutical, food-grade systems)

- Reduced surface contamination risk

- High corrosion resistance without surface oxidation

- Improved flow efficiency

All tubes are annealed in a controlled atmosphere furnace, ensuring a smooth, shiny surface without oxide scaling.

Testing & Quality Assurance

DLSS ensures every Super Duplex S32750 tube is produced under strict quality control:

- 100% Eddy Current Testing

- Hydrostatic or Pneumatic Pressure Testing

- PMI (Positive Material Identification)

- Surface Roughness & Dimensional Checks

- Optional Third-Party Inspection (TÜV, SGS, BV, etc.)

- Certified EN 10204 3.1B Test Reports

All tubes are manufactured in accordance with ASTM A789 and customer-specific tolerances, ensuring complete traceability and compliance.

Packaging & Delivery

- Packaging: Plywood cases, plastic end caps, moisture barrier wraps

- Delivery: Worldwide shipping via sea/air with full documentation

- MOQ: Flexible based on project size

Summary Table

| Feature | Details |

|---|---|

| Material | S32750 Super Duplex Steel |

| Size | 19 × 2.4 mm |

| Surface Finish | Bright Annealed |

| Type | Seamless Tube |

| Standard | ASTM A789 / ASME SA789 |

| Main Use | Heat Exchangers, Marine, Oil & Gas, Chemical |

| Strength | Ultra-High Yield and Tensile |

| Resistance | Chloride SCC, Pitting, Oxidation |

Call to Action

Need Super Duplex Tubing for Critical Applications?

DLSS offers factory-direct prices, fast production turnaround, and expert engineering support.

Contact us today to request a quote or speak with an application specialist:

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let’s make your next project stronger, longer-lasting, and more efficient.