Meta Description:

Explore why stainless steel tubes are essential in desalination plants. Understand material selection, corrosion resistance, and DLSS’s tubing solutions for seawater applications.

Introduction

As global freshwater demand surges, desalination—the process of turning seawater into potable water—is expanding rapidly. But desalination environments are among the most corrosive and challenging in industrial processing.

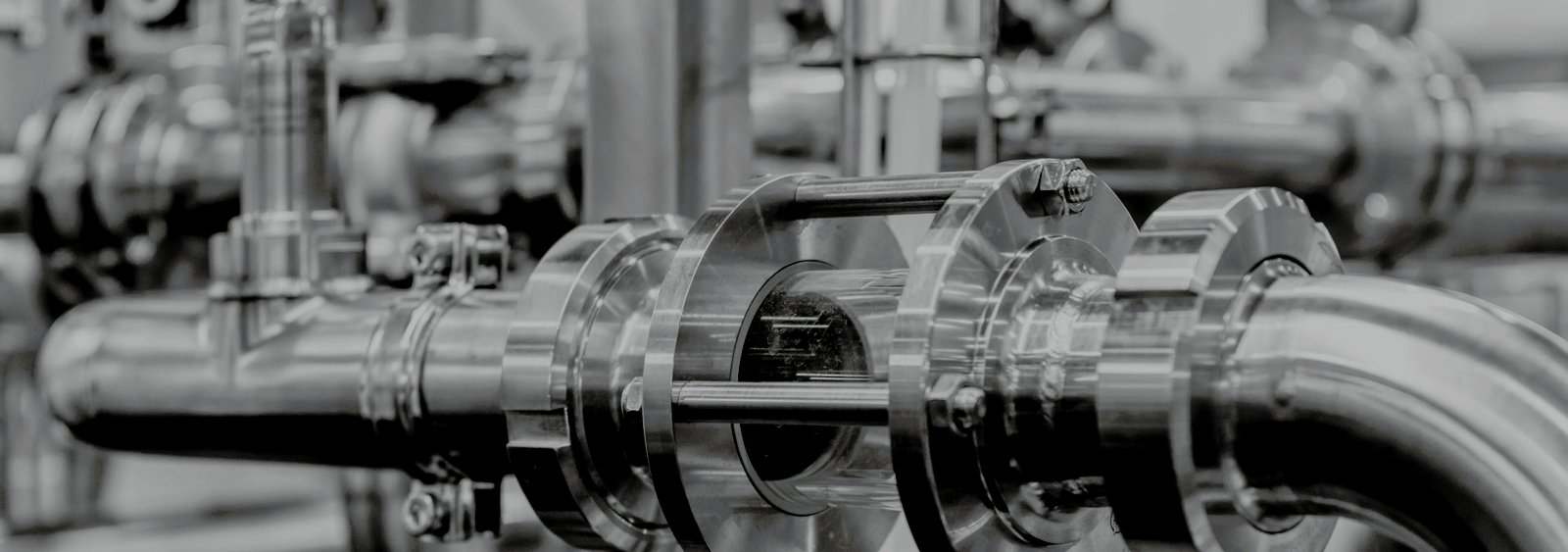

To withstand high chloride content, elevated pressures, and continuous flow, desalination systems rely heavily on stainless steel tubes—particularly in evaporators, heat exchangers, and reverse osmosis units.

DLSS manufactures and supplies high-performance seamless stainless steel tubes for desalination projects worldwide, with materials optimized for seawater durability and lifecycle cost-efficiency.

1. Why Desalination Plants Need High-Quality Tubing

Desalination systems operate in extreme conditions:

- Continuous exposure to chloride-rich seawater

- High temperature and pressure cycles

- Demanding heat transfer efficiency

- Risk of stress corrosion cracking and pitting corrosion

Using inferior tubing materials can lead to premature failure, increased maintenance, or plant shutdown.

2. Best Stainless Steel Grades for Desalination

| Grade | Corrosion Resistance | Typical Use | PREN* Value |

|---|---|---|---|

| TP316L | Good | General RO systems, low-chloride zones | ~24 |

| 904L (N08904) | Very Good | Brine heaters, evaporators | ~34 |

| S32205 (Duplex) | Excellent | MSF/ME evaporators, seawater piping | ~35–38 |

| S32750 (Super Duplex) | Outstanding | High-chloride RO systems, outfall lines | >40 |

| Alloy 825 (N08825) | Excellent | Thermal vapor compression, condensers | ~32 |

*PREN = Pitting Resistance Equivalent Number. Higher = better chloride resistance.

Source: Nickel Institute – Seawater Corrosion

3. Where Stainless Tubes Are Used in Desalination

- Heat exchangers (shell & tube type)

- Brine heaters and condensers

- Intake and outfall pipelines

- Evaporator chambers in MSF & MED systems

- High-pressure piping in RO skids

- Thermal vapor compression units

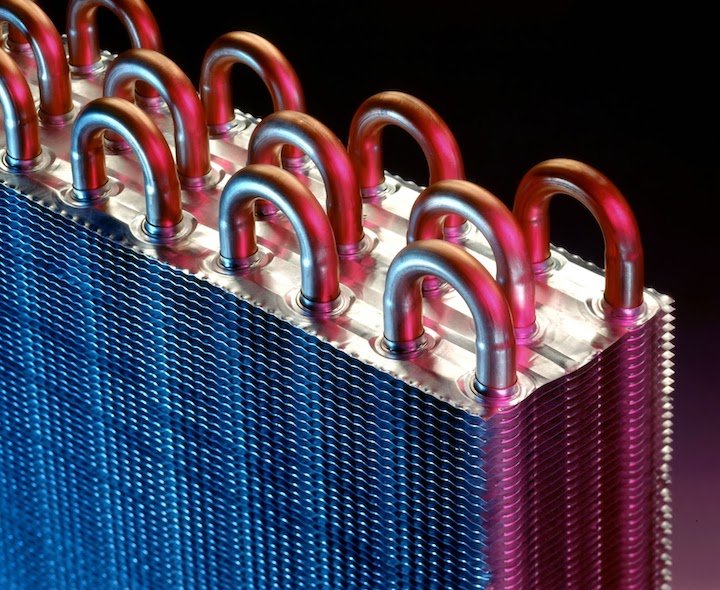

DLSS supplies straight and U-bent seamless tubes with smooth internal surfaces and tight tolerance, improving heat transfer and minimizing fouling.

4. DLSS Solutions for Desalination Projects

- Material Range: 316L, 904L, S32205, S32750, Incoloy 825

- Standards: ASTM A213, ASTM B111, EN 10216-5, NACE MR0175

- Inspection: 100% Eddy Current Testing, Hydrotest, PMI, and Grain Size

- Surface Finish: Pickled & passivated, Bright Annealed (BA), or Polished

- Bend Options: Fixed U-bends with post-bend heat treatment

- Documentation: EN 10204 3.1 / 3.2 MTCs, ITPs, NDE reports available

- Third-Party Inspection: Available with SGS, BV, TUV, Lloyd’s

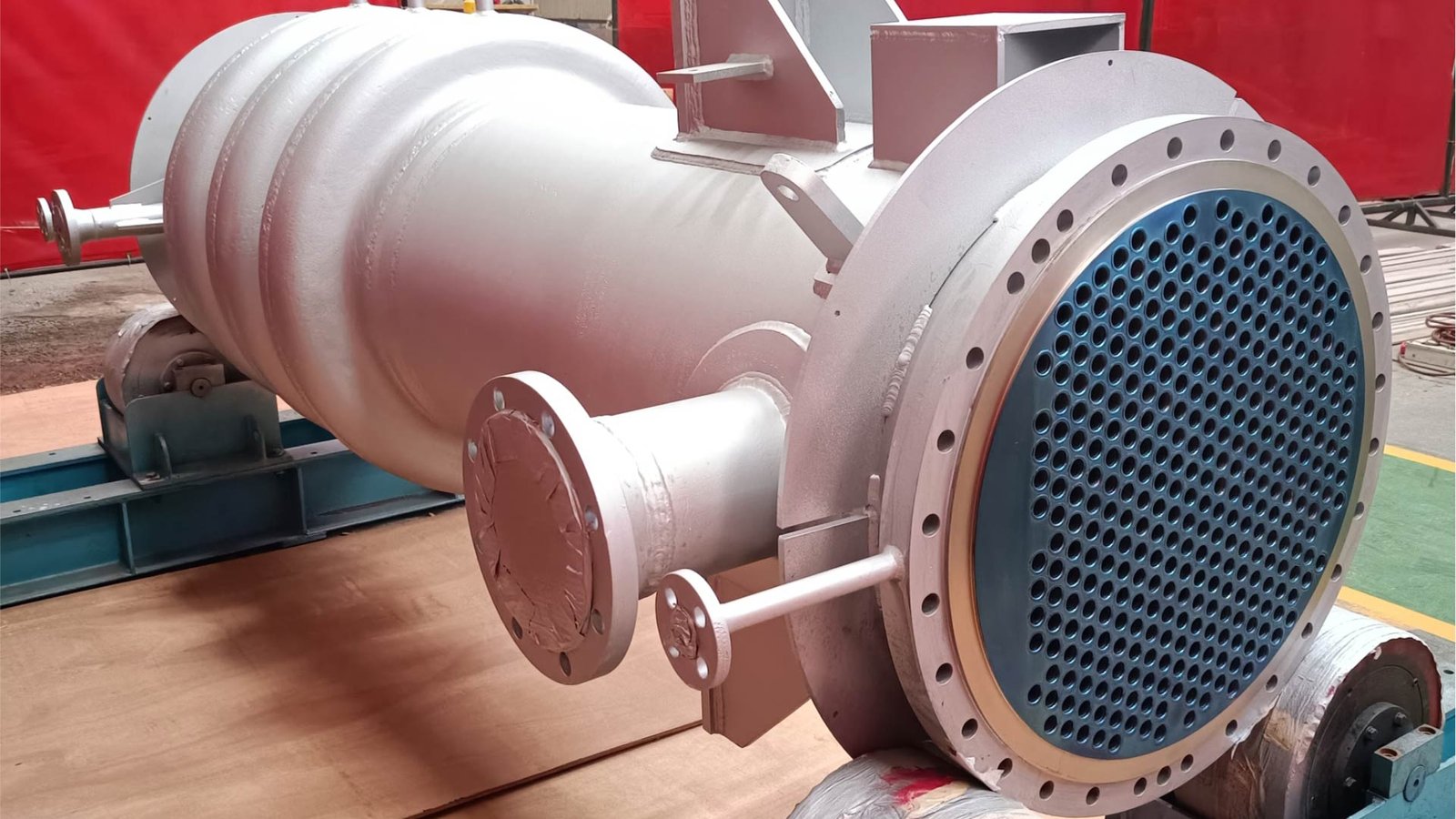

5. Case Study: Duplex Tubes in Middle East Desalination Plant

Client: EPC Contractor for GCC water utility

Scope: 80 tons of S32205 duplex stainless steel tubes

Use: Shell & tube heat exchangers in MED system

Requirements:

- ASTM A789 compliance

- U-bent, pickled & passivated

- Eddy Current + Hydrostatic Testing

- Witness inspection by Lloyd’s Register

Result: DLSS delivered full package within 45 days, tubes passed FAT, and system is now running continuously with no corrosion signs reported after 12 months.

6. How to Choose the Right Material

When selecting stainless tubes for desalination:

- Evaluate chloride concentration

- Consider flow velocity and turbulence

- Check for design codes (e.g., ASME, EN, API)

- Verify tube finish: smooth surfaces reduce scale build-up

- Ensure traceability and test results are included in the MTC

Further reading: European Desalination Society – Technical Papers

Conclusion

Desalination plants demand robust, corrosion-resistant tubing to ensure long-term reliability. At DLSS, we combine metallurgy expertise, precision manufacturing, and international testing standards to deliver stainless steel tubes built for the harshest marine environments.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Planning a desalination project? DLSS offers tailored stainless steel tube solutions—contact our technical sales team today to discuss material grades, testing plans, and delivery timelines.