Meta Description:

Confused between ASTM A213 and A269 stainless steel tube standards? Learn the key differences in application, tolerances, testing, and suitability for heat exchangers and process systems.

Introduction

Two of the most frequently specified standards for stainless steel tubing are ASTM A213 and ASTM A269.

Both cover austenitic stainless steel tubes like TP304L, TP316L, and TP321. However, their scope, tolerances, and test requirements differ significantly—especially for heat exchanger and pressure service applications.

This article provides a clear, side-by-side comparison to help you choose the right standard for your tubing project.

What Is ASTM A213?

ASTM A213 is a standard specification for seamless tubes used in boilers, superheaters, and heat exchangers.

- Applies to seamless and welded tubes

- Designed for high temperature and pressure service

- Typically used in power plants, petrochemical, and oil & gas systems

- Requires flattening, flaring, hardness, and hydro testing

View the official ASTM A213 scope

What Is ASTM A269?

ASTM A269 is a general-purpose tubing specification for austenitic stainless steel.

- Allows both welded and seamless tubes

- Covers tubes for low or moderate pressure

- Common in instrumentation, food, dairy, and sanitary systems

- Testing includes flattening and flaring, but hydrostatic test is optional unless specified

View the official ASTM A269 scope

Key Differences Table

| Feature | ASTM A213 | ASTM A269 |

|---|---|---|

| Scope | Boiler, superheater, exchanger tubes | General service, instrumentation |

| Tube Type | Seamless / Welded | Seamless / Welded |

| Wall Thickness | Specified as minimum wall | Specified as average wall |

| Operating Conditions | High temp & pressure | Low to moderate pressure |

| Hydrostatic Test | Mandatory | Optional unless ordered |

| Surface Finish Options | Pickled / Bright Annealed | BA / EP / Polished (commonly for sanitary) |

| Common Grades | TP304H, TP316H, TP321H, TP347H | TP304L, TP316L, TP316Ti |

| Industry Use | Power, chemical, refinery, exchanger | Food, pharma, instrumentation |

When to Use Each Standard

- Use ASTM A213 when the tubes are part of a pressure-retaining system, such as:

- Steam boilers

- Heat exchanger bundles under pressure

- Thermal oil systems

- High-temp hydrogen service

- Use ASTM A269 when the tubes are for non-pressure or clean-service piping, such as:

- CIP/SIP lines

- Sanitary transfer

- Gas or utility tubing

- Instrument signal lines

DLSS Tube Offerings by Standard

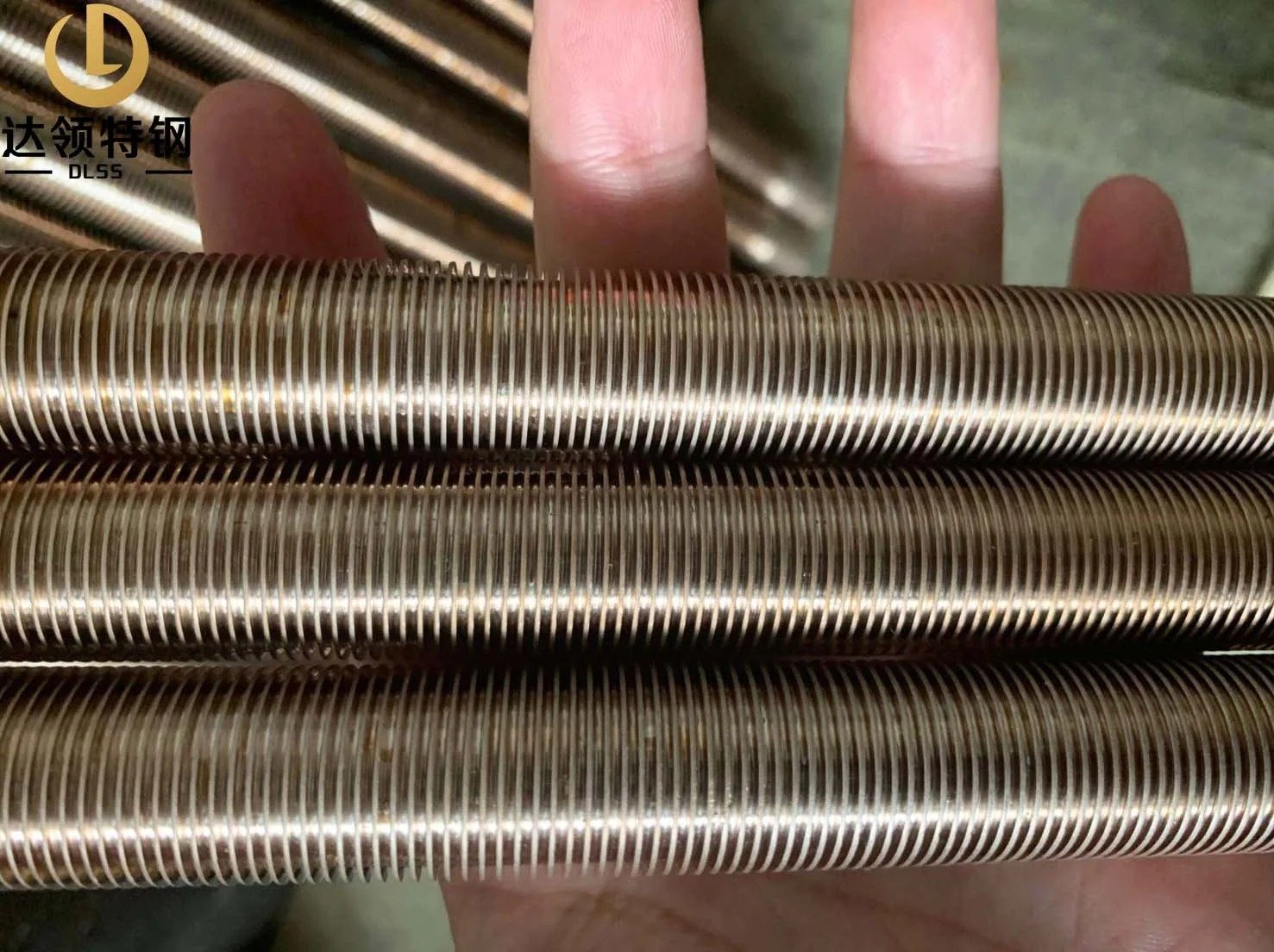

DLSS supplies both A213 and A269 tubes with:

- Seamless TP316L / TP321 / TP347H

- ID cleaning and pickling / BA / EP finishes

- Testing: hydrostatic, eddy current, PMI, visual

- EN 10204 3.1 / 3.2 certificates

- Third-party inspection by SGS, TUV, BV

Frequently Asked Questions (FAQ)

Q1: Can I substitute A269 for A213 in heat exchangers?

Only in non-pressurized or auxiliary circuits. A213 is required for pressure-rated shell & tube exchangers.

Q2: What’s the meaning of “minimum wall” vs “average wall”?

A213 specifies the minimum allowable wall thickness, while A269 allows average wall, which can vary slightly across the length.

Q3: Are both standards available with electropolished surface?

Yes. Especially for A269 in food/pharma. A213 is less frequently EP but available on request.

Q4: Does DLSS offer technical help for material selection?

Yes. Our team helps match application conditions with the right grade, standard, and testing protocol.

Conclusion

Understanding the differences between ASTM A213 and A269 is critical for ensuring code compliance, long service life, and system safety.

Whether you need pressure-rated seamless tubes or clean-service sanitary tubing, DLSS provides certified products built to international standards—delivered with full documentation and QA support.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com