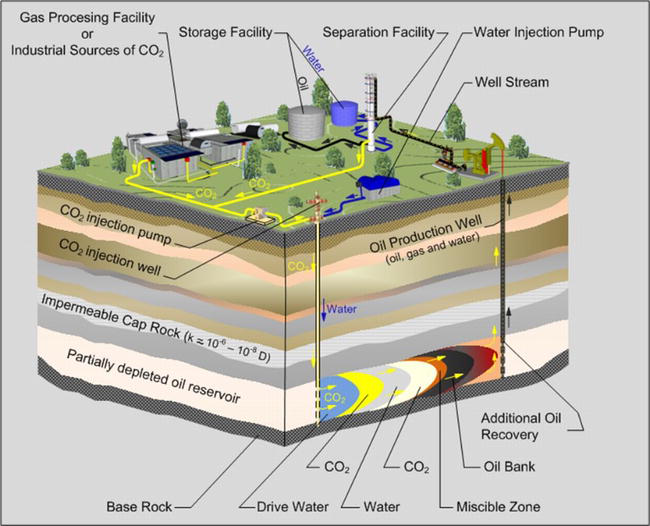

As countries ramp up efforts to reach net-zero emissions, Carbon Capture, Utilization, and Storage (CCUS) technologies are being deployed at scale. These systems capture CO₂ from industrial processes or power generation and inject it deep underground—or repurpose it for industrial use.

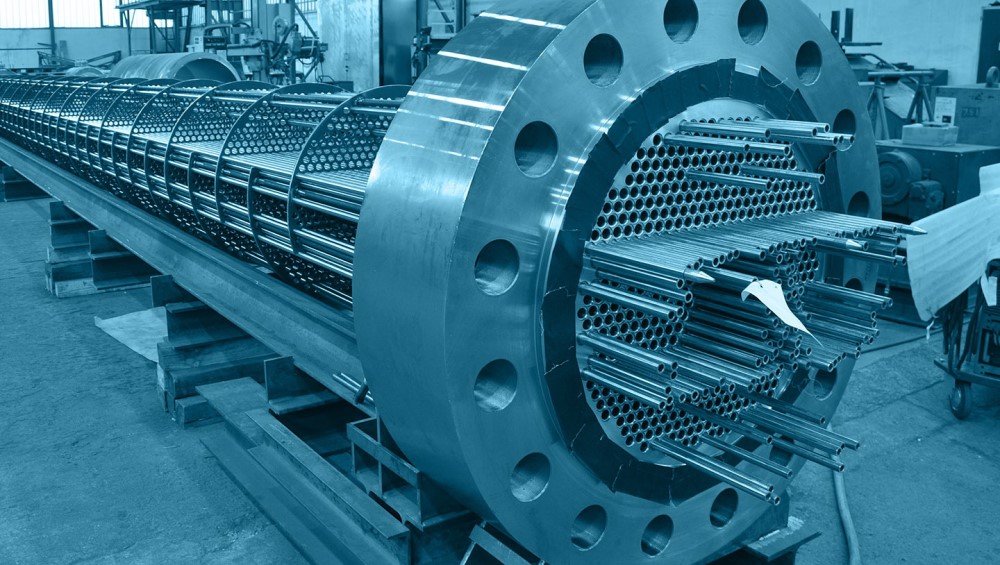

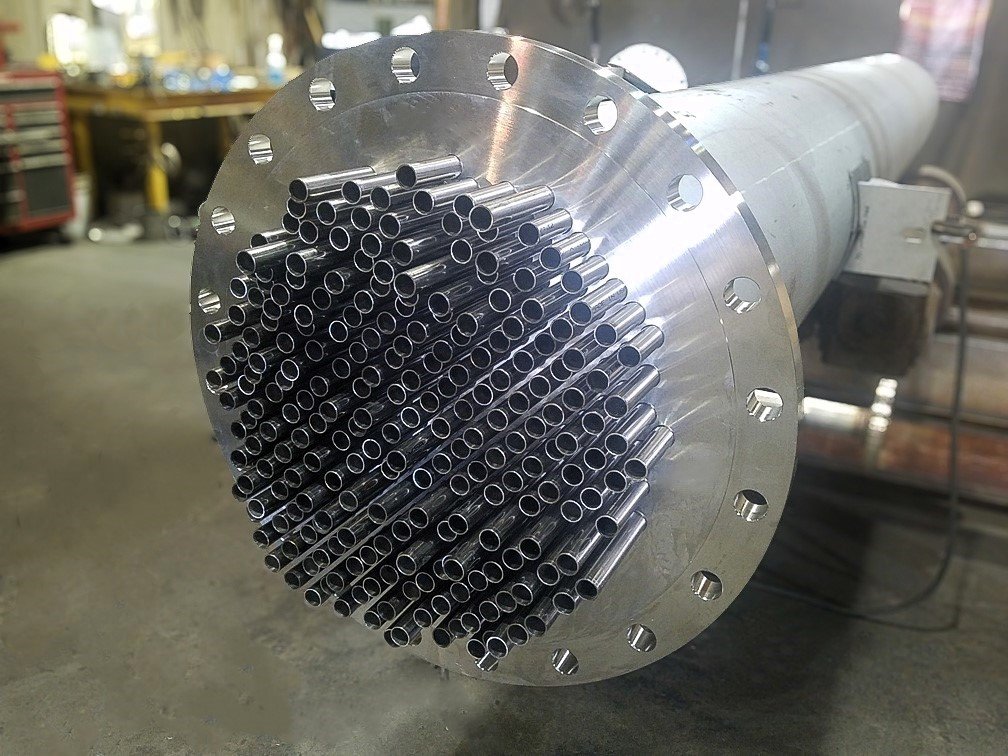

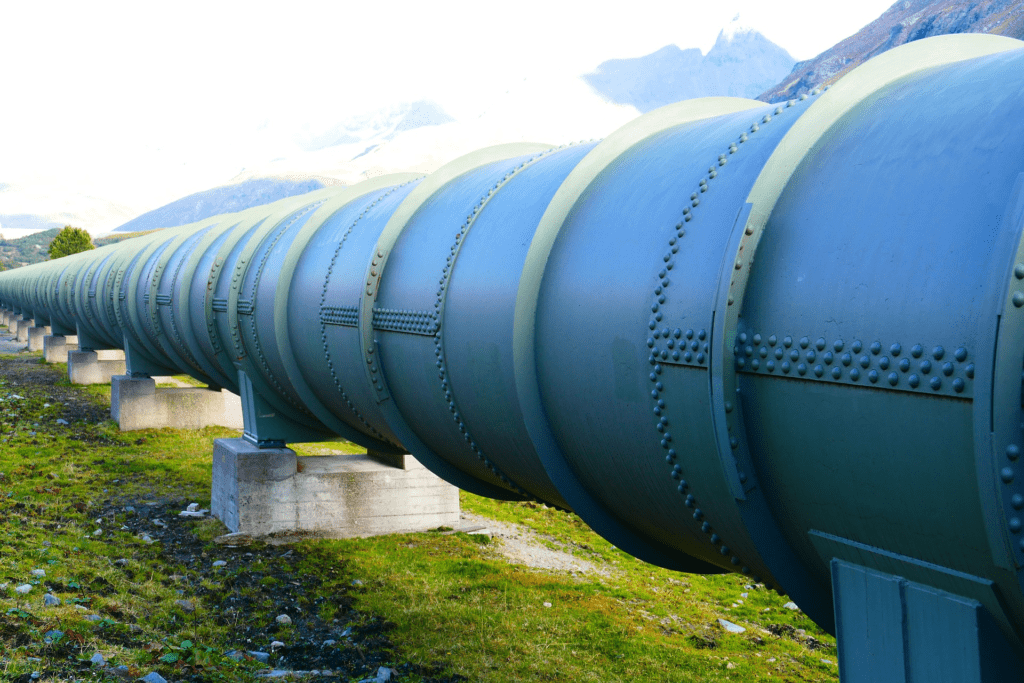

But behind every CCUS facility lies a network of high-performance stainless steel piping and heat exchangers engineered to handle high-pressure CO₂, amine-based solvents, moisture, and contaminants.

1. Why CCUS Systems Require Specialized Tubing

CO₂ is deceptively aggressive in high-concentration, high-pressure environments:

- Corrosion risk increases with water content, H₂S, or NOx in flue gas

- Amine absorption and regeneration systems create cyclic thermal and chemical stress

- Compression and liquefaction stages demand seamless tubes rated for 100–250 bar

- Supercritical CO₂ (sCO₂) requires precision wall thickness and tight concentricity

According to the Global CCS Institute, over 200 new CCUS projects are in development worldwide, from gas separation to blue hydrogen facilities.

2. Typical Tube Applications in CCUS Plants

| System Area | Material Requirements |

|---|---|

| Amine absorber/reboiler | TP316L / TP317L with low carbon, pickled & passivated |

| CO₂ compression cooling | Seamless tubes for condensers, SA213 / A312 |

| Drying & filtration units | Clean ID surfaces, Ra ≤ 0.6μm, hydro-tested |

| sCO₂ turbines (future tech) | High-temp alloys (e.g., 347H, Inconel 625) |

| Injection lines | Clad or duplex piping to resist acid gas + CO₂ |

Tubes for these systems must balance mechanical strength, corrosion resistance, and tight fabrication tolerance.

3. What Projects Are Underway?

| Country | Project | Tube Needs |

|---|---|---|

| USA | Petra Nova, ExxonMobil Baytown | Amine reboiler & compression piping |

| Norway | Northern Lights | CO₂ pipeline-grade stainless + 3.2 certs |

| China | Sinopec Qilu CCUS Project | TP316L high-pressure seamless coils |

| Saudi Arabia | Aramco Blue Hydrogen | Heat exchanger tubes in gas separation |

| UK | Net Zero Teesside | ASME/PED-compliant steam piping systems |

EPC contractors are increasingly requesting full material certification (EN 10204 3.1/3.2), NDT reports, and PED/ASME Section VIII compliance.

4. What Tube Qualities Are Critical for CCUS Systems?

| Feature | Why It Matters |

|---|---|

| Low carbon content (L grades) | Reduce risk of sensitization, especially in amine-rich environments |

| Smooth internal finish | Improve flow, reduce fouling in gas-liquid exchangers |

| Tight wall thickness control | Withstand cycling pressure (100–250 bar) |

| Clad or duplex options | Protect against acid gas and sour service |

| Documentation and TPI support | Most projects require third-party inspections or witnessed hydro tests |

DLSS, for example, provides SA213 TP316L and S32205 duplex tubes for critical CCUS applications, with full test reports, packaging, and seaworthy delivery.

Frequently Asked Questions (FAQ)

Q1: Why is TP316L often used in CO₂ capture systems?

A: Its molybdenum content and low carbon level improve resistance to corrosion in amine systems and under high-pressure CO₂ exposure.

Q2: Are seamless tubes necessary for CCUS applications?

A: Yes—particularly for high-pressure, cyclic environments (e.g., compression, injection). Seamless tubes offer better strength and leak resistance.

Q3: What documentation is needed for CCUS project deliveries?

A: EN 10204 3.1 or 3.2 certificates, PMI results, NDT reports, hydro test logs, packing list with full traceability, and often third-party inspection approval.

Q4: Are duplex or clad tubes common in CCUS pipelines?

A: Increasingly yes—especially when CO₂ is mixed with H₂S or other aggressive gases. S32205 or Incoloy 825 cladding may be specified.

Conclusion: Building the Backbone of Decarbonization

CCUS systems are central to the world’s low-carbon future—and the pipes and tubes they depend on must perform under extraordinary chemical and physical stress.

For stainless steel tube manufacturers, this means more than just compliance—it means understanding process conditions, providing engineering support, and delivering reliability with every bundle.

At DLSS, we don’t just supply pipe—we help build the pipelines of tomorrow’s cleaner energy system.