Why High-Temperature Applications Require Specialized Tubes

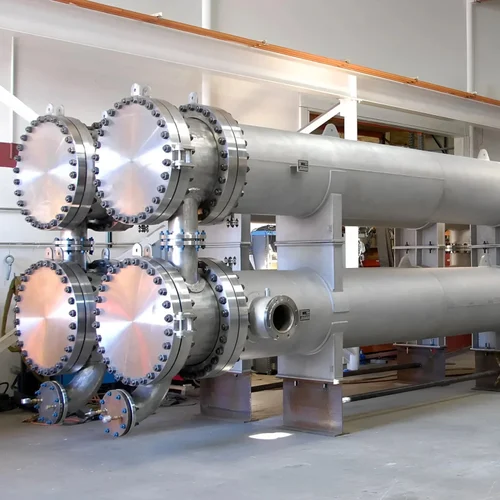

Boilers, reheaters, and furnace coils operate in environments that push materials to their thermal limits. Stainless steel tubes used in these systems must withstand continuous exposure to temperatures ranging from 500°C to over 1000°C, while also resisting oxidation, creep deformation, and thermal fatigue.

Without proper material selection, high temperatures can cause scaling, strength loss, embrittlement, or even rupture. That’s why selecting high-temperature resistant stainless steel tubing is critical for safety, performance, and long-term reliability.

Recommended Stainless Steel & Alloy Tubes for High-Temperature Applications

1. TP304H / TP316H — Austenitic Tubes for Elevated Temp Use

- High carbon variants of 304/316 with better creep strength

- Suitable for superheaters and reheaters under 600°C

- Conform to ASTM A213 / ASME SA213

2. TP347H / 321H — Stabilized Stainless Tubes

- Niobium or titanium stabilized to resist intergranular corrosion at high temperatures

- Good structural stability under thermal cycling

- Widely used in boiler headers, steam piping, and heat recovery systems

3. 310S / 253MA — High-Temp Oxidation-Resistant Tubes

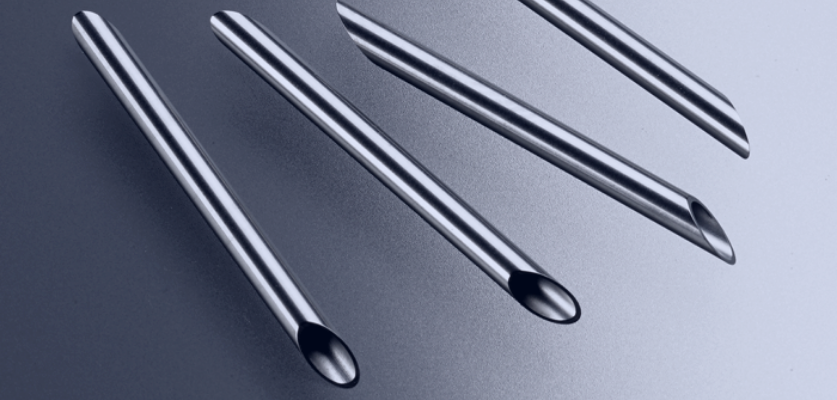

- Outstanding resistance to oxidation up to 1150°C

- Ideal for radiant heater tubes, furnace burners, and thermal processing lines

- 253MA offers better mechanical strength with nitrogen and rare earth elements

4. Incoloy 800H / 800HT — Nickel-Iron-Chromium Alloy Tubes

- Excellent resistance to oxidation, carburization, and thermal creep

- Often used in ethane/ethylene cracker furnaces, reformers, and high-pressure boilers

- Compliant with ASTM B407 and ASME Code Cases

Key Properties to Consider for High-Temperature Stainless Tubes

| Property | Importance in High-Temp Service |

|---|---|

| Creep Resistance | Prevents long-term deformation at high stress and temperature |

| Oxidation & Carburization Resistance | Ensures tube integrity in air or combustion atmospheres |

| Thermal Fatigue Resistance | Withstands repeated temperature cycling in startup/shutdown systems |

| Microstructure Stability | Prevents grain coarsening and embrittlement over time |

| Compliance with Boiler Codes | ASTM A213, A335, EN 10216-2, ASME Section I / VIII |

Global Industry Trends in High-Temperature Tube Applications

- Power plants are switching from carbon steel to TP347H and 310S to meet emission and efficiency requirements

- Refineries and hydrogen plants are increasingly using Incoloy 800H in reformer outlet systems

- Waste-to-energy and biomass boilers prefer 253MA stainless steel tubes for better oxidation resistance and service life

DLSS Expert Insight

“Clients often ask if 304L can be used in boilers. While it’s fine for low-temp systems, once you exceed 550°C, you must consider H-grade stainless steel or high-nickel alloys. We provide tailored support to ensure creep rupture strength, oxidation resistance, and code compliance are met.”

— DLSS High-Temperature Product Team

Frequently Asked Questions (FAQ)

Q1: Can regular 304 stainless steel be used for boiler tubes?

No. Use TP304H or TP347H, which offer better high-temperature strength and oxidation resistance.

Q2: What’s the temperature limit for 310S tubes?

310S can typically withstand continuous use at 1050°C, with short-term exposure up to 1150°C.

Q3: When should I choose 800H over 310S?

For long-term exposure above 800°C where creep resistance is critical, 800H or 800HT are better choices than 310S.

Conclusion: High-Temperature Performance Requires the Right Alloy

Operating under extreme heat demands materials engineered for thermal strength and surface stability. DLSS supplies high-temperature stainless steel and alloy tubes that meet the world’s most stringent boiler, heater, and pressure vessel standards.

With 30+ years of experience, third-party test support, and traceable heat batches, we ensure safe, durable, and code-compliant delivery for your high-temp systems.