In the oil and gas industry, process reliability, corrosion resistance, and thermal efficiency are critical to success. Among the most vital components enabling these outcomes are tubular heat exchangers, particularly shell and tube heat exchangers (STHEs). From upstream production to downstream refining, these systems provide the thermal control required in some of the world’s most demanding environments.

This article explores key application areas of tubular heat exchangers in oil and gas operations, the technical challenges they address, and the material and design considerations critical to their performance.

Why Tubular Heat Exchangers Dominate in Oil and Gas

The oil and gas industry requires heat exchanger designs capable of withstanding:

- High pressure and temperature

- Corrosive or sour gas environments (H₂S, CO₂, chlorides)

- Heavy hydrocarbons and fouling-prone fluids

- Stringent mechanical and certification standards (ASME, API 660)

The shell and tube configuration is ideal due to its durability, flexibility, and easy maintenance. Learn more: Shell and Tube Heat Exchanger – Wikipedia

Key Application Areas in Oil & Gas

1. Crude Oil Preheaters

In crude distillation units, tubular exchangers are used to preheat crude oil before entering the furnace. This reduces fuel consumption and increases system efficiency.

Design Considerations:

- High-temperature resistance (300°C+)

- Low-fouling tubes (Duplex or Incoloy materials)

- TEMA-type BEM or BEU exchangers

2. Gas Sweetening and Amine Regeneration

Used to remove H₂S and CO₂ from natural gas streams using amine solutions. Heat exchangers are essential in rich/lean amine heat recovery and reboiler duties.

Material Tip: Use 316L, 904L, or Duplex to resist amine-induced corrosion.

3. Condensers in Gas Processing

Tubular condensers are widely used to condense hydrocarbons or steam in NGL (Natural Gas Liquids) processing.

Preferred Designs:

- U-tube bundles for thermal expansion

- API 660 or ASME Section VIII compliance

- Titanium or Cu-Ni tubes in corrosive services

4. Hydrocracking & Catalytic Reforming Units

These high-pressure, high-temperature processes demand robust heat recovery systems to manage hydrogen-rich and acidic process streams.

Recommended Materials:

- Inconel, Hastelloy, or Cladded Stainless Steel

5. Offshore and Subsea Applications

Seawater-cooled exchangers for gas compression, glycol regeneration, or utility cooling on offshore platforms.

Challenges: Salt-laden environments, tight space

Solutions: Super Duplex or Titanium tubes, compact U-tube bundles

More reference: Corrosion in offshore systems – Wikipedia

DLSS Capabilities for Oil & Gas Projects

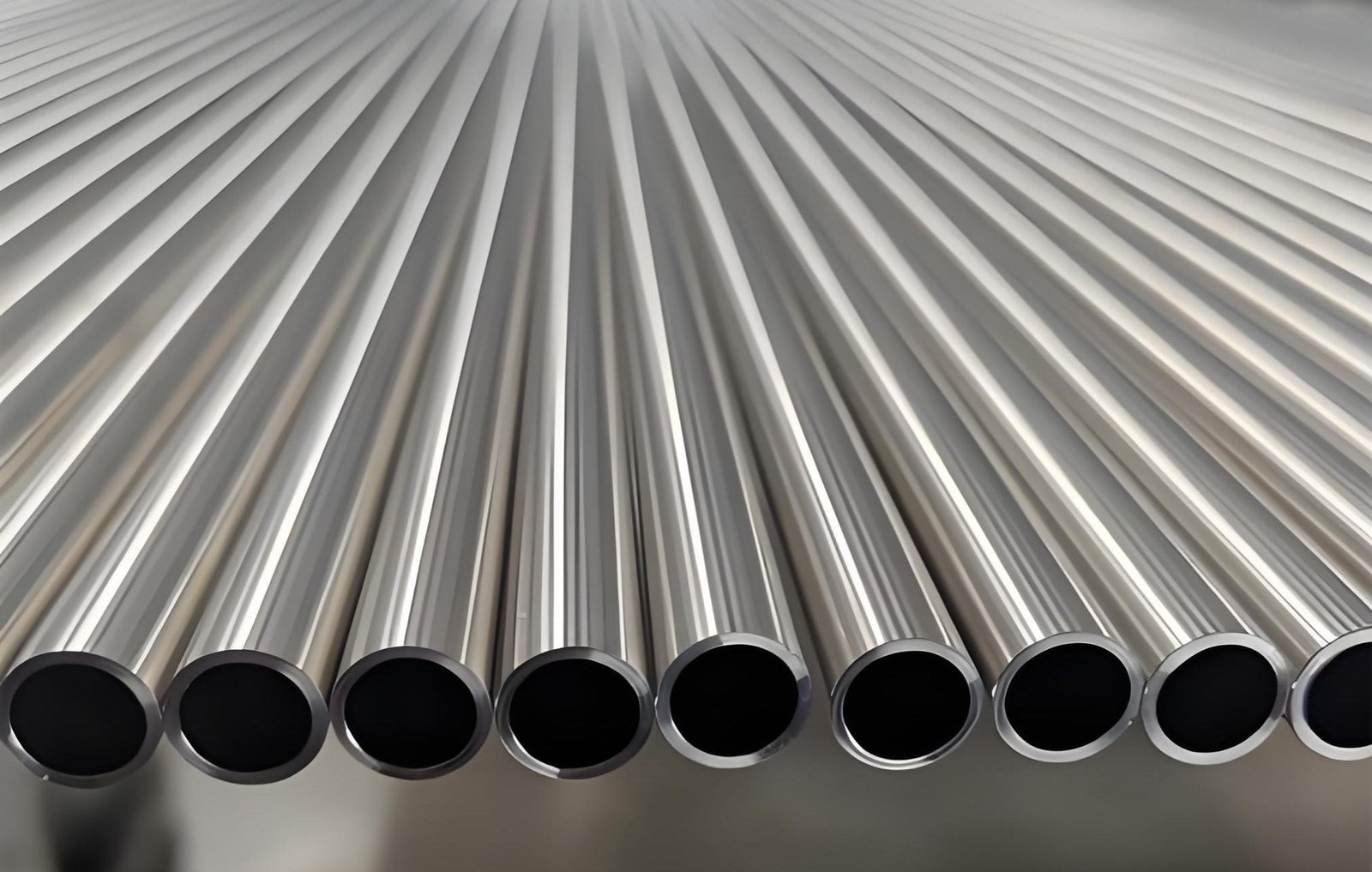

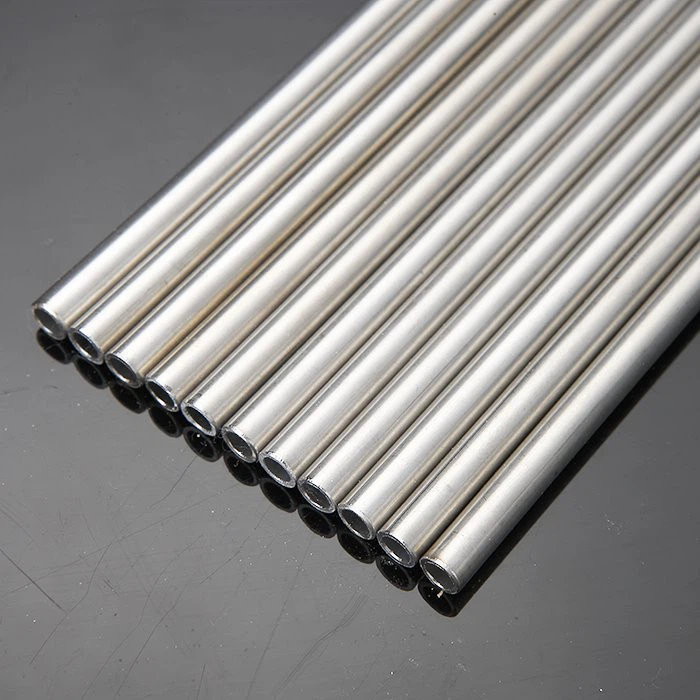

As a specialized manufacturer of heat exchanger tubes, DLSS supports EPC contractors, oil companies, and OEMs with high-performance tubular solutions:

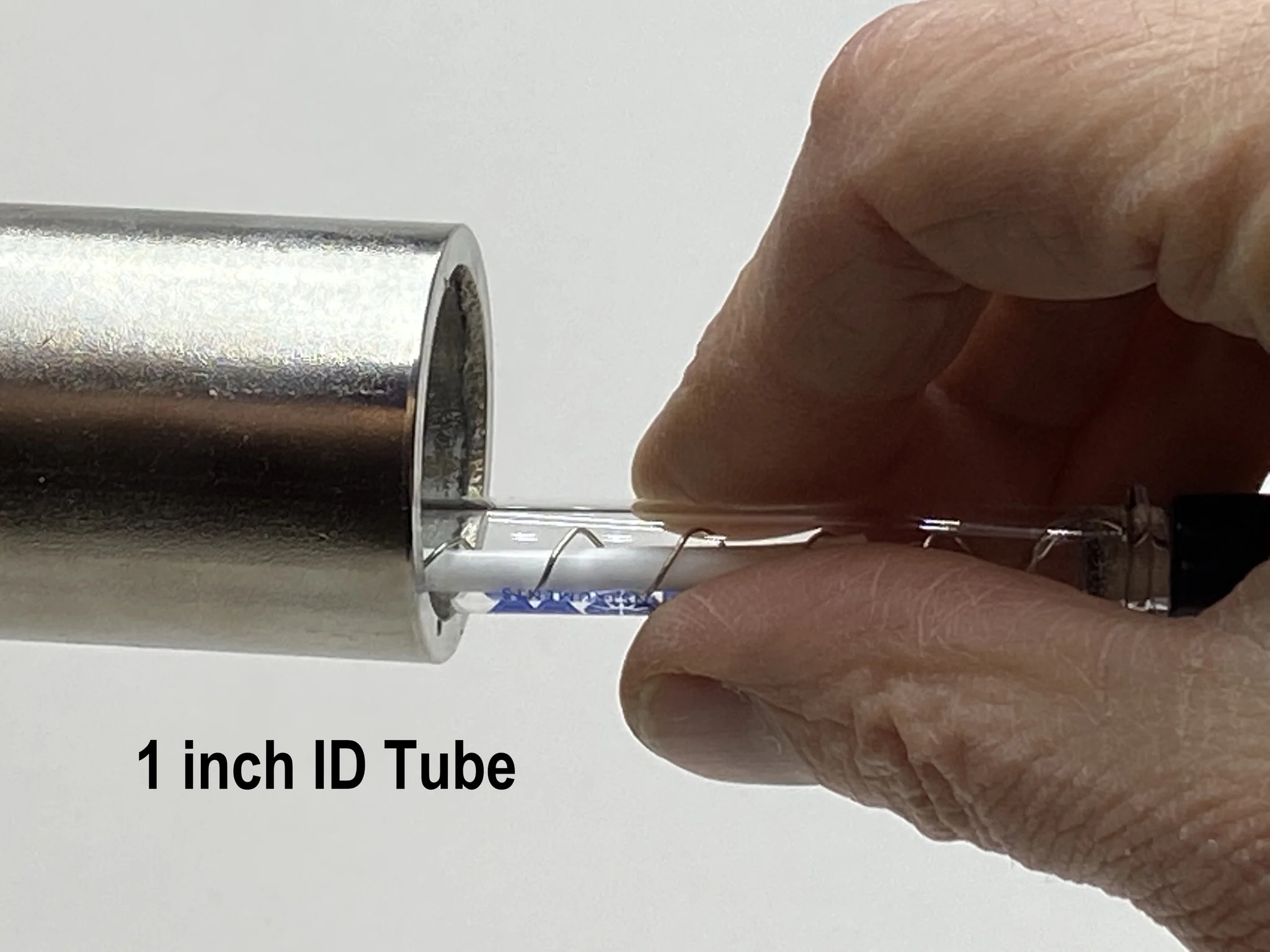

- Seamless tubes in 316L, 317L, Duplex, Super Duplex, Titanium, and Nickel Alloys

- Lengths up to 22 meters with tight dimensional control

- Support for ASME, PED, API 660, and EN 10216-5

- 100% PMI, hydrostatic testing, eddy current testing, and customized packaging for offshore delivery

Explore more: DLSS Heat Exchanger Tube Solutions

Frequently Asked Questions (FAQ)

Q1: Which materials are most suitable for sour gas (H₂S) environments?

Answer: Duplex and Super Duplex stainless steels (e.g., UNS S32205, S32750) offer excellent resistance to sulfide stress cracking.

Q2: How are heat exchangers designed for thermal expansion in hydrocarbon applications?

Answer: U-tube designs or floating head configurations are preferred to accommodate differential expansion.

Q3: Are DLSS tubes compliant with NACE MR0175?

Answer: Yes, upon request. We offer tubes that meet NACE and ISO 15156 corrosion standards for H₂S-containing environments.

Contact Us

DLSS provides tailored tubing solutions for the most challenging oil & gas projects. Our team works closely with your engineers and procurement teams to ensure timely, certified, and high-performance deliveries.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let us be your trusted partner in heat exchanger performance and reliability.