Meta Description:

Explore how stainless steel seamless pipes are critical in oil & gas—covering upstream, midstream, downstream, offshore, pipelines and more—with practical insights and sourcing tips.

Introduction

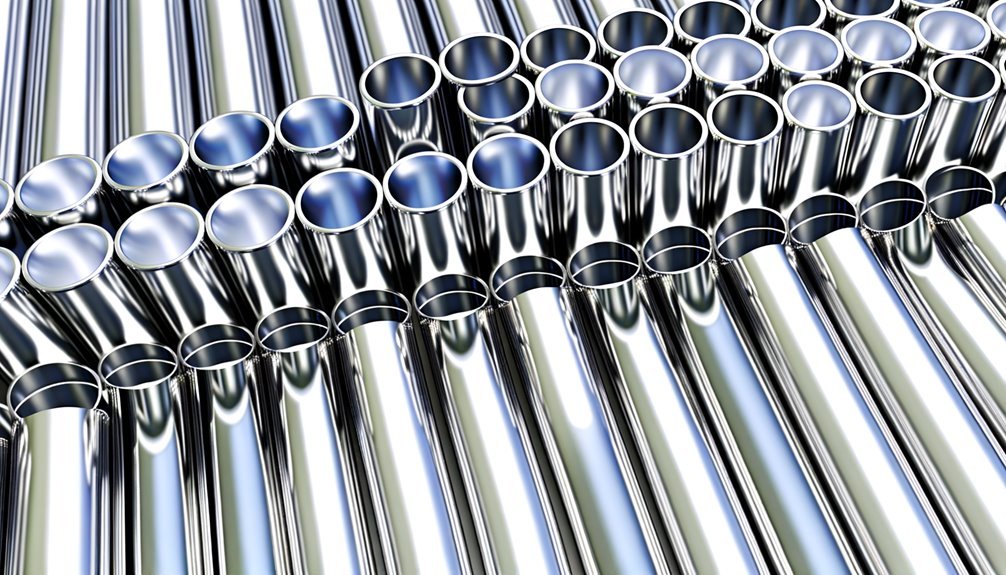

In the global steel market, stainless steel seamless pipes are projected to grow from USD 3.88 B in 2025 to USD 5.15 B by 2030, driven largely by demand in the oil and gas sector linkedin.com+1gerabnationalenterprises.com+1marketsandmarkets.com+4globenewswire.com+4marketsandmarkets.com+4. Their unmatched resistance to high pressure, corrosion, and temperature make them essential across the entire petroleum value chain.

1. Upstream: Drilling, Wellheads & Subsea Systems

In upstream operations—deep wells, offshore platforms, and drilling rigs—stainless seamless pipes excel due to uniform pressure capability and reliability:

- Drill strings and production tubing often specify grades such as ASTM A312 TP316L or high-alloy options like Duplex 2205 and 904L en.wikipedia.org.

- Their seamless construction enables high-pressure performance, critical underwater or downhole, avoiding the weld-related weaknesses found in ERW pipes marketresearchfuture.com+15unifiedalloys.com+15sunastm.com+15.

- SSC-resistance is mandatory under standards like NACE MR0175/0103.

2. Midstream: Gathering Lines & Transmission Pipelines

Midstream operations—compressors, pump stations, and long-haul pipelines—demand corrosion resistance and strength:

- Stainless seamless pipes transport natural gas, refined fuels, and oil with fewer joint failures.

- As infrastructure ages, operators increasingly retrofit with Duplex or Super Austenitic (e.g., 254 SMO) tubing to combat harsh environments gerabnationalenterprises.com+1fedsteel.com+1sunastm.comen.wikipedia.org.

- With growth in carbon capture & storage (CCS), companies like Nippon Steel are committing to long-term supply agreements reuters.com+1globenewswire.com+1.

3. Downstream: Refineries & Petrochemical Plants

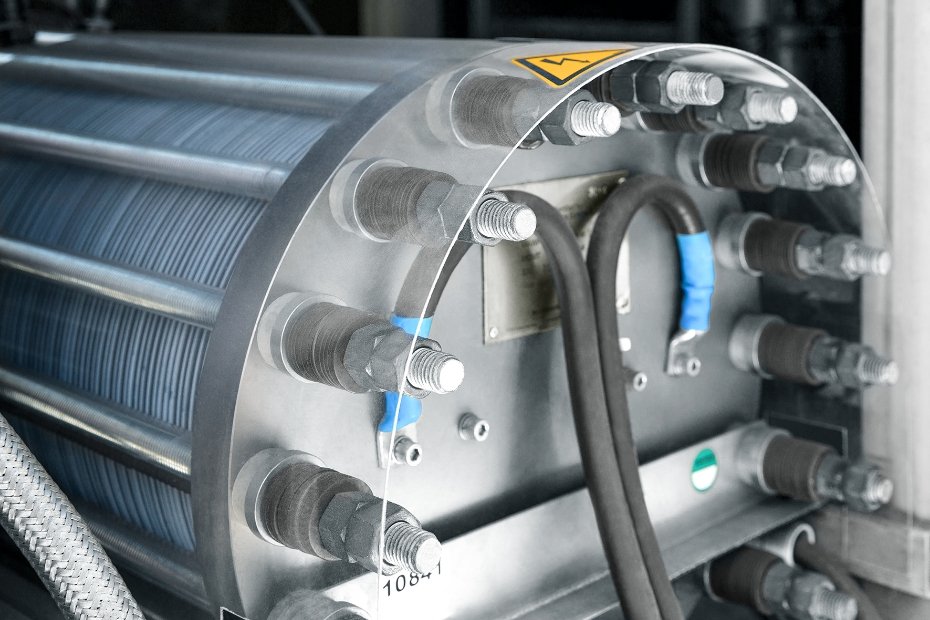

Refineries require corrosion-resistant tubes in various equipment:

- Heat exchangers, condensers and reactors often use TP316L, TP321 or advanced alloys like 904L for acid, sulfur, or chloride resistance unifiedalloys.com+1bmstainless.com+1champaksteel.com.

- In olefin, ammonia and benzene production, seamless pipes resist thermal stress and cyclic conditions inherent to chemical processing.

4. Offshore & Marine Environments

Seawater, salt spray, and mechanical stress make offshore tubing challenging:

- Stainless grades like CuNi, Inconel, and Duplex stand up to seawater corrosion and biofouling.

- Specifications like those from Naval Sea Systems Command endorse Admiralty Brass and copper–nickel tubing globenewswire.com+5santoshsteels.com+5nipponsteel.com+5.

- Seamless construction ensures fewer weld joints—critical for avoiding crevice corrosion.

5. High-Pressure & High-Temperature Service

Beyond oil & gas, stainless seamless pipes serve in:

- Steam, superheated fluid, and high-pressure lines in refineries and power plants.

- Duplex and Super Duplex pipes (e.g., SAF 2205) offer twice the strength of 316L, ideal for such extreme conditions champaksteel.comsantoshsteels.com+4linkedin.com+4globenewswire.com+4en.wikipedia.org.

Global Market Trend

Market analysts report the Stainless Steel Seamless Pipes market is fueled by energy projects:

- Asia-Pacific leads in market share, driven largely by oil & gas infrastructure nipponsteel.com+13globenewswire.com+13marketsandmarkets.com+13.

- Despite higher initial costs vs welded pipes, demand remains high for long-term reliability and reduced maintenance .

- Global projection: from USD 3.37 B (2024) to USD 5.15 B by 2030 at a 5.8 % CAGR marketsandmarkets.com+1globenewswire.com+1.

Material Selection Guide

| Service Location | Recommended Grades | Typical Standards |

|---|---|---|

| Subsea, downhole | TP316L, Duplex 2205, 904L | ASTM A312, NACE MR0175 |

| Gathering & pipelines | Duplex, 254 SMO, Super Duplex | ASTM A789, EN 10216-5 |

| Heat exchangers | TP321/H, 904L, 254 SMO | ASTM A213, A312 |

| Offshore seawater | CuNi, Admiralty Brass | ASTM B111, CuNi standards |

| High-temp steam | SAF 2205, Inconel alloys | ASTM A789, ASME II |

Why Operators Choose DLSS Stainless Seamless Pipes

- Tailored solutions in TP316L, 904L, 254 SMO, Duplex (S32205) and Super Duplex

- Full certification: EN 10204 3.1/3.2, NACE MR0175/0103

- Options in U-bend, bright annealed, pickled or polished finishes

- NDT & hydrostatic testing for safety and compliance

- Global export packaging, shipping to +40 countries

Conclusion

Stainless steel seamless pipes are a strategic asset in oil & gas—from upstream to downstream and offshore to onshore. Their reliability, resistance to harsh environments, and compliance with stringent standards make them indispensable.

For long service life and peace of mind in critical energy applications, trust DLSS for precision stainless seamless piping solutions.

Contact Us

Email: info@dlsspipe.com

Website: www.dlsspipeline.com