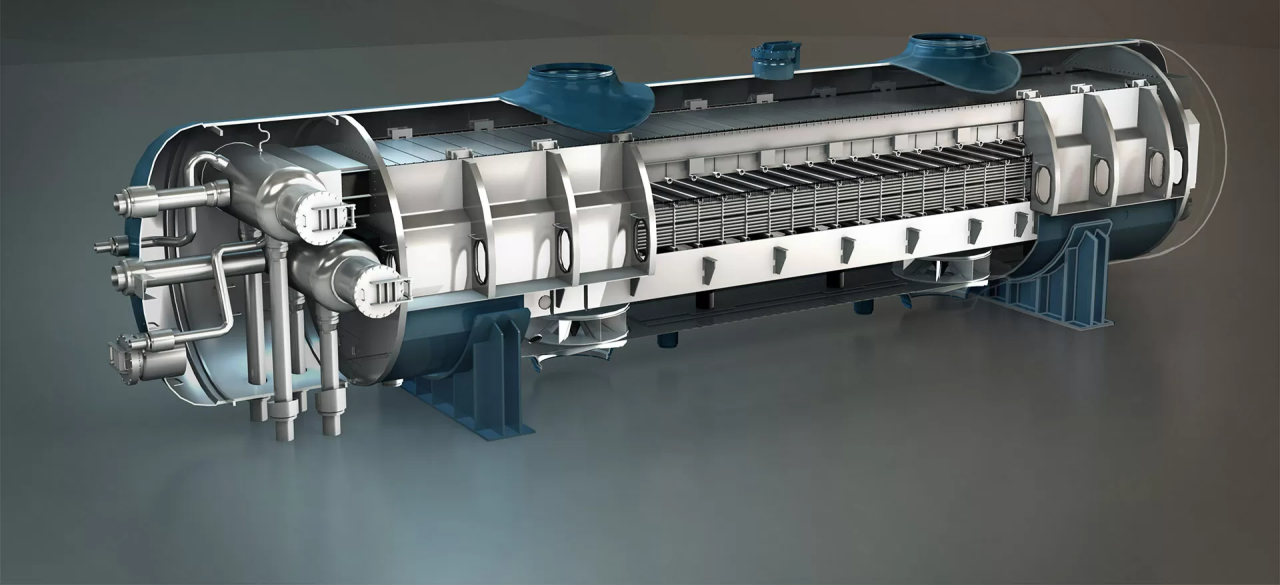

In global heat exchanger projects, engineers and procurement teams often face a critical question: Which material standard should we follow—ASME, EN, or JIS?

Each of these standards governs stainless steel tube production but comes from different regions and technical philosophies. Understanding their differences helps avoid miscommunication, ensure regulatory compliance, and make smart sourcing decisions.

In this article, we compare the key features, dimensional tolerances, material equivalents, and application regions of ASME, EN, and JIS standards—with insights from DLSS Pipeline, a manufacturer experienced in supplying multi-standard stainless steel heat exchanger tubes globally.

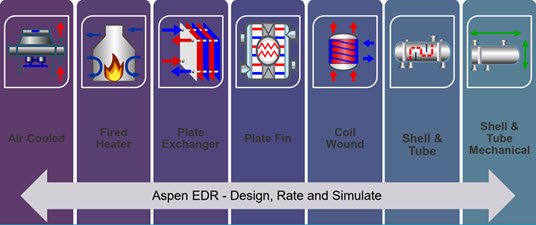

1. Overview of the Standards

| Standard | Full Name | Origin | Common Usage |

|---|---|---|---|

| ASME | American Society of Mechanical Engineers | USA/North America | Power, oil & gas, industrial sectors |

| EN | European Norm (CEN standards) | EU | EU, Middle East, PED-regulated projects |

| JIS | Japanese Industrial Standards | Japan | Japan, Southeast Asia, legacy projects |

2. Material Grade Equivalents

| ASME (ASTM) | EN (EN 10028/10216-5) | JIS (G3463) |

|---|---|---|

| TP304 | 1.4301 (X5CrNi18-10) | SUS304 |

| TP304L | 1.4307 (X2CrNi18-9) | SUS304L |

| TP316 | 1.4401 (X5CrNiMo17-12-2) | SUS316 |

| TP316L | 1.4404 (X2CrNiMo17-12-2) | SUS316L |

| TP317L | 1.4438 | SUS317L |

| S31803 | 1.4462 | SUS329J3L |

Note: Mechanical properties and chemical composition are similar, but allowable tolerances and test methods vary.

3. Dimensional Tolerances Comparison

| Property | ASME (A450) | EN (ISO 1127 D4/T3) | JIS (G3463) |

|---|---|---|---|

| OD Tolerance | ±0.79 mm typical | ±0.75% of OD (T3 level) | ±0.3–0.5 mm depending on OD |

| WT Tolerance | ±12.5% standard | ±10% (or customized T4) | ±12.5% typical |

| Length Tolerance | ±3.2 mm (fixed length) | ±10 mm (L1 class) | ±5 mm typical |

| Straightness | ≤1.5 mm/m | ≤1.5 mm/m | ≤1.5 mm/m |

DLSS offers dimensional flexibility and can meet any of these standards upon request. Visit www.dlsspipeline.com

4. Testing Requirements

| Test Item | ASME SA213 / A450 | EN 10216-5 / EN 10217-7 | JIS G3463 |

|---|---|---|---|

| Hydrostatic Test | Required | Required | Required |

| Eddy Current Test | Optional / as agreed | Required for seamless tubes | Optional |

| Tensile Test | Yes | Yes | Yes |

| Hardness Test | Optional | If specified | If specified |

| Flattening Test | Required for seamless | Not required | Required |

| PMI | Optional / by spec | Often mandatory (PED) | Optional |

Important note: European PED projects often require third-party inspection (EN 10204 3.2) and traceability—DLSS can provide both.

5. Regional and Project Preferences

- ASME: Widely used in USA, Canada, Latin America, and international oil & gas projects

- EN: Mandatory in Europe and PED-compliant regions (e.g., Middle East, North Africa)

- JIS: Common in Japan, and legacy projects in South Korea, Thailand, Vietnam

DLSS supports global EPCs, OEMs, and fabricators with documentation packages customized to your target market.

Frequently Asked Questions (FAQ)

Q1: Can I substitute TP316L with 1.4404?

Yes, these are equivalent in chemical composition and mechanical properties. Just confirm the testing requirements and tolerance class.

Q2: Does DLSS support multi-standard projects?

Absolutely. We provide ASME, EN, and JIS certified tubes with full traceability and cross-reference labels.

Q3: What if my client requires dual certification?

DLSS offers dual-certified tubes (e.g., TP316L / 1.4404) with shared test results and conformity statements.

Conclusion

Selecting the right standard for your heat exchanger tube depends on project location, industry regulations, and customer expectations. Whether you’re working under ASME, EN, or JIS, it’s essential to understand the differences and ensure your supplier can deliver accordingly.

DLSS Pipeline offers stainless steel heat exchanger tubes that comply with all major international standards—trusted by engineers and EPCs across more than 40 countries.

Let us help you streamline your next global project.