Meta Description:

Confused between ASTM A270 and ASME BPE sanitary tube standards? Learn the key differences in tolerance, surface finish, and certification, especially for food, beverage, and pharmaceutical applications.

Introduction

When sourcing sanitary stainless steel tubes for use in food, beverage, or pharmaceutical industries in Latin America, two standards dominate global procurement:

- ASTM A270

- ASME BPE

At first glance, both appear to specify hygienic tubing. But choosing the correct one depends on your application, surface requirements, and regulatory environment—especially for exports to the U.S. or Europe.

What Is ASTM A270?

ASTM A270 is a standard issued by ASTM International for seamless and welded austenitic stainless steel tubing intended for dairy and food processing applications.

It defines:

- Acceptable stainless steel grades (e.g., TP304, TP316L)

- Tolerances for OD, wall thickness, and length

- Surface finishes (mechanically polished, electropolished)

- Tests: Eddy current, hydrostatic, PMI

- Optional surface roughness (Ra) limits

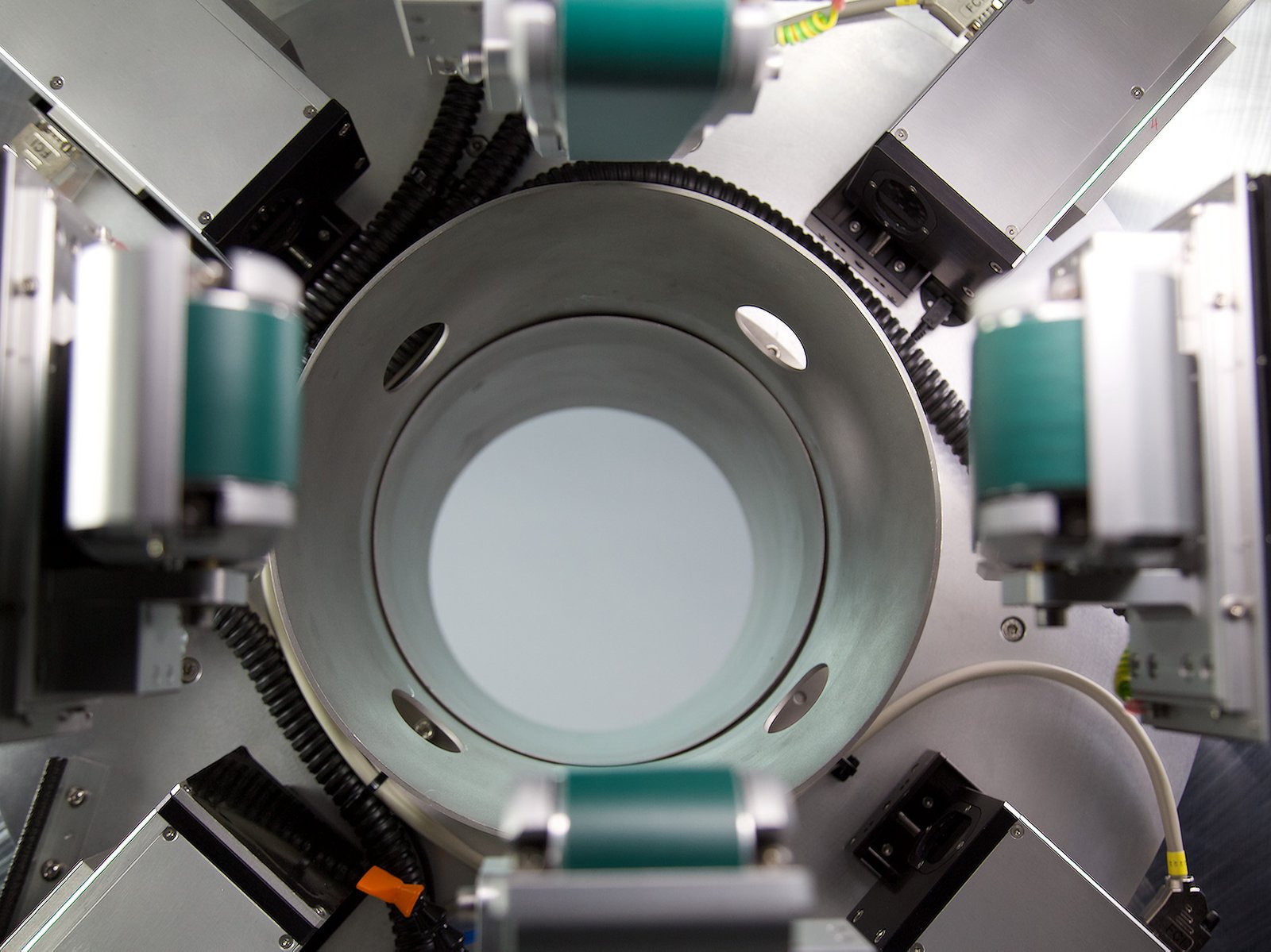

What Is ASME BPE?

ASME BPE (Bioprocessing Equipment) is a more stringent standard developed by the American Society of Mechanical Engineers, focusing on pharmaceutical, biotechnological, and high-purity applications.

It includes:

- Tight manufacturing tolerances

- Strict Ra surface finish control (ID & OD)

- Bead removal, passivation, and electropolishing requirements

- Documentation for validation and traceability

- Dimensional consistency for orbital welding

ASME BPE is often required for applications involving injectables, vaccines, and high-purity water.

Key Differences: ASTM A270 vs ASME BPE

| Feature | ASTM A270 | ASME BPE |

|---|---|---|

| Industry Focus | Food, dairy, general sanitary | Biotech, pharma, high-purity |

| Surface Roughness (ID) | Optional Ra ≤ 0.8 µm | Mandatory Ra ≤ 0.51 µm (mechanical polish), ≤ 0.38 µm (EP) |

| Weld Bead Treatment | Optional | Required bead removal, smoothing |

| Electropolishing (EP) | Optional | Often required |

| Testing Requirements | Eddy current, hydrostatic | Same, plus surface mapping and docs |

| Documentation | Optional 3.1 MTC | Required validation and full traceability |

| Cost | Moderate | Higher due to precision and compliance |

Which Should You Choose in Latin America?

Choose ASTM A270 if:

- You are manufacturing food, beverage, dairy, or juice systems

- Cost and availability are critical

- You’re exporting under general sanitary compliance (e.g., FDA, ISO 22000)

Choose ASME BPE if:

- You’re building biotech or pharmaceutical lines

- You’re exporting medical devices or injectable production systems

- Regulatory traceability and welding precision are critical

Note: Some dairy and brewing projects in Brazil and Chile now specify BPE for export-level sanitation.

DLSS Capabilities for Both Standards

| Feature | ASTM A270 | ASME BPE |

|---|---|---|

| Grades | TP304, TP316L | TP316L, 1.4404 (for EP) |

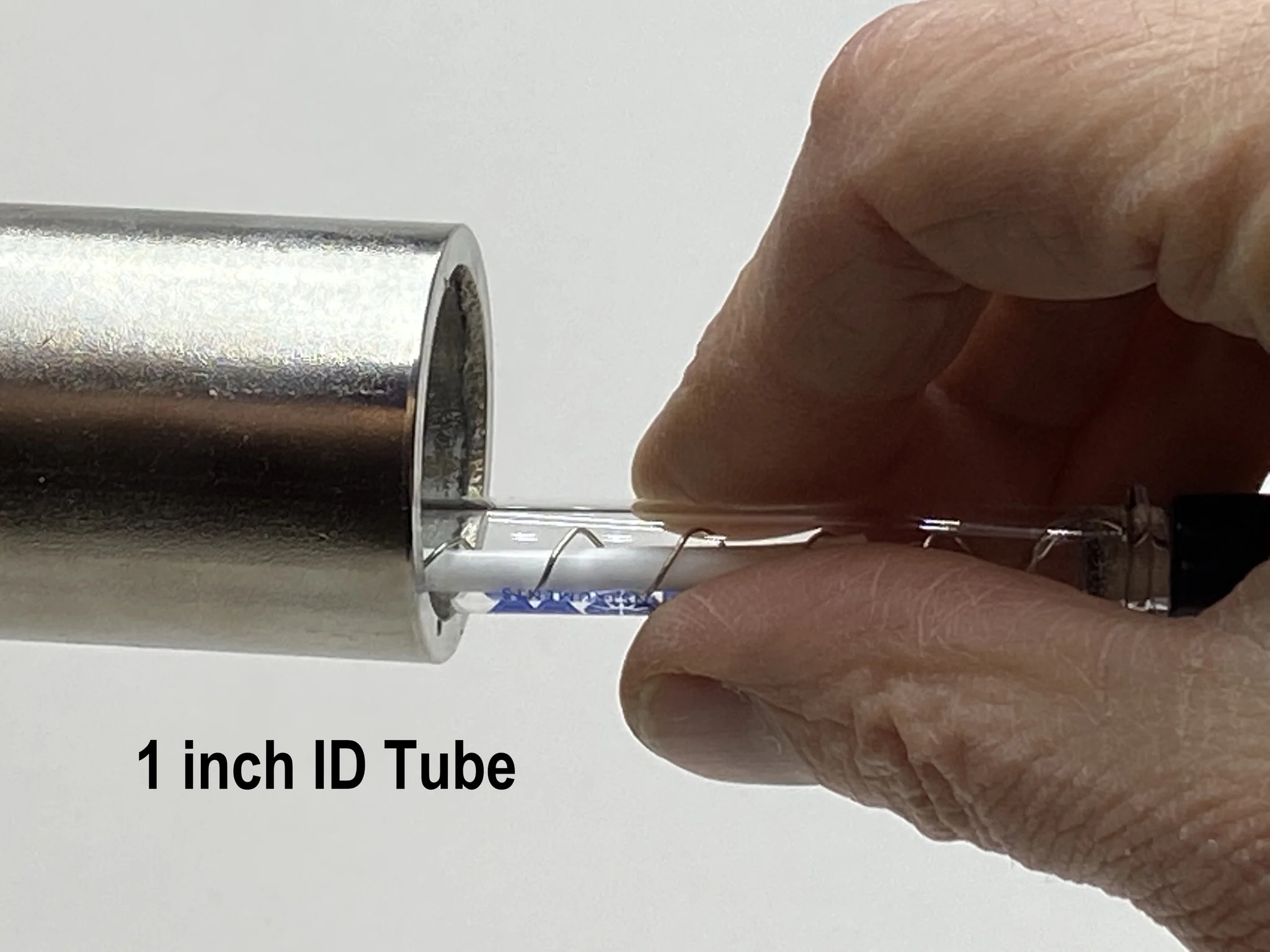

| Size Range | 12.7 mm – 114.3 mm | ½” – 4” (welding-compatible dimensions) |

| Surface Finish | MP, MP+EP, Ra ≤ 0.8 µm | EP, Ra ≤ 0.38 µm, 100% bead removal |

| Documentation | EN 10204 3.1 | Full BPE validation, Ra mapping, heat trace |

| Delivery Region | Brazil, Argentina, Colombia, Chile | Export projects to EU/US pharma customers |

FAQs

Q1: Can A270 tubes be used in pharma production?

For non-injectable production (like nutritional supplements), yes. But injectable or biotech-grade systems typically require ASME BPE.

Q2: Do you offer ASME BPE-certified electropolished tubes?

Yes. DLSS supplies EP tubes with full Ra test, bead removal, passivation, and documentation.

Q3: What’s the cost difference between A270 and BPE?

ASME BPE tubes may be 25–40% more expensive due to stricter tolerances and post-processing.

Conclusion

Understanding the difference between ASTM A270 and ASME BPE is essential when specifying sanitary tubing for Latin American industries. Choosing the right standard ensures regulatory compliance, long-term performance, and customer trust—especially when targeting global markets.

DLSS offers full support for both standards, helping clients in food, beverage, and pharmaceutical sectors across South America choose with confidence.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need a quotation or technical consultation on sanitary tube standards? Contact us today—we help you meet compliance and exceed expectations.