Offshore oil platforms, marine vessels, and coastal industrial facilities require custom finned tube solutions that can withstand the challenges of seawater corrosion, high humidity, and continuous operation. At DLSS, we specialize in designing and manufacturing offshore and marine finned tube heat exchanger components with precision engineering and enhanced durability.

For understanding different finned tube types, see our Spiral vs Extruded Finned Tube Comparison. For maintenance tips, check Finned Tube Cleaning and Maintenance Best Practices.

1. Unique Challenges in Offshore and Marine Environments

- High Corrosion Risk – Continuous exposure to seawater and salty air accelerates metal degradation.

- Biofouling – Marine organisms attach to tube surfaces, reducing heat transfer efficiency.

- High Pressure & Temperature Variations – Offshore systems experience fluctuating loads and operational cycles.

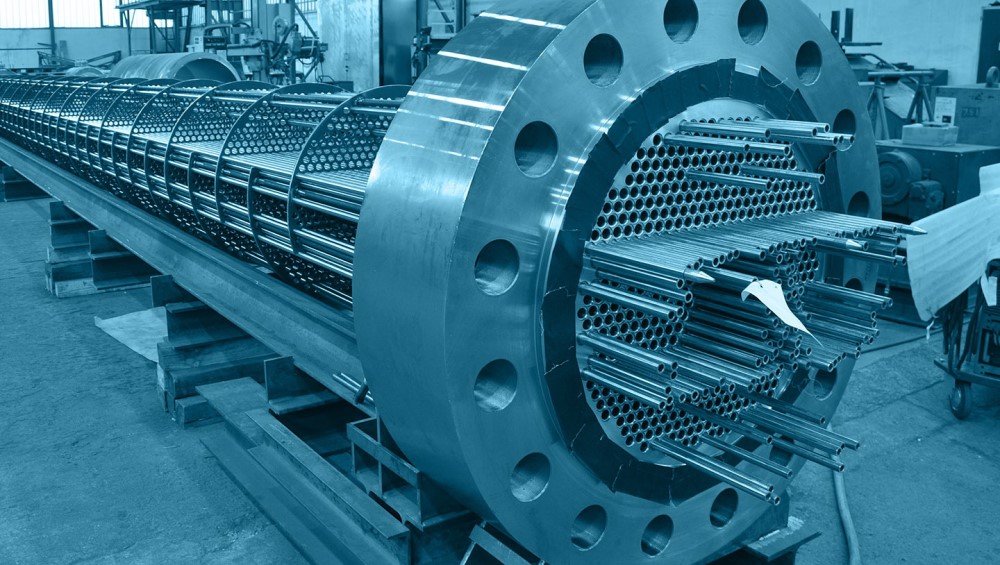

2. DLSS Custom Design Solutions

- Material Selection – Titanium, Cu-Ni alloys, and super duplex stainless steel for maximum corrosion resistance.

- Protective Coatings – Anti-fouling and anti-corrosion coatings for longer service life.

- Optimized Fin Geometry – Custom fin spacing and height for better performance in high-humidity conditions.

- Precision Manufacturing – CNC-controlled fin winding and extrusion for consistent quality.

3. Benefits of DLSS Offshore & Marine Finned Tubes

- Extended operational life in seawater environments

- Reduced maintenance downtime

- Enhanced heat transfer efficiency

- Compliance with ABS, DNV, and NORSOK standards

4. Applications

- Offshore oil and gas production platforms

- Marine vessel condensers and coolers

- Coastal power plants

- Desalination plants

5. Related Reading

DLSS provides complete offshore and marine finned tube solutions, from design to delivery, ensuring your heat exchangers operate efficiently under the toughest conditions.

Contact us today at info@dlsspipe.com or visit www.dlsspipeline.com for tailored heat exchanger component solutions.