1. Introduction – Energy Savings in Heat Exchangers

Industrial facilities often spend a significant portion of their energy budget on heating and cooling processes. Optimizing heat exchanger performance not only lowers energy consumption but also extends equipment life and reduces maintenance costs.

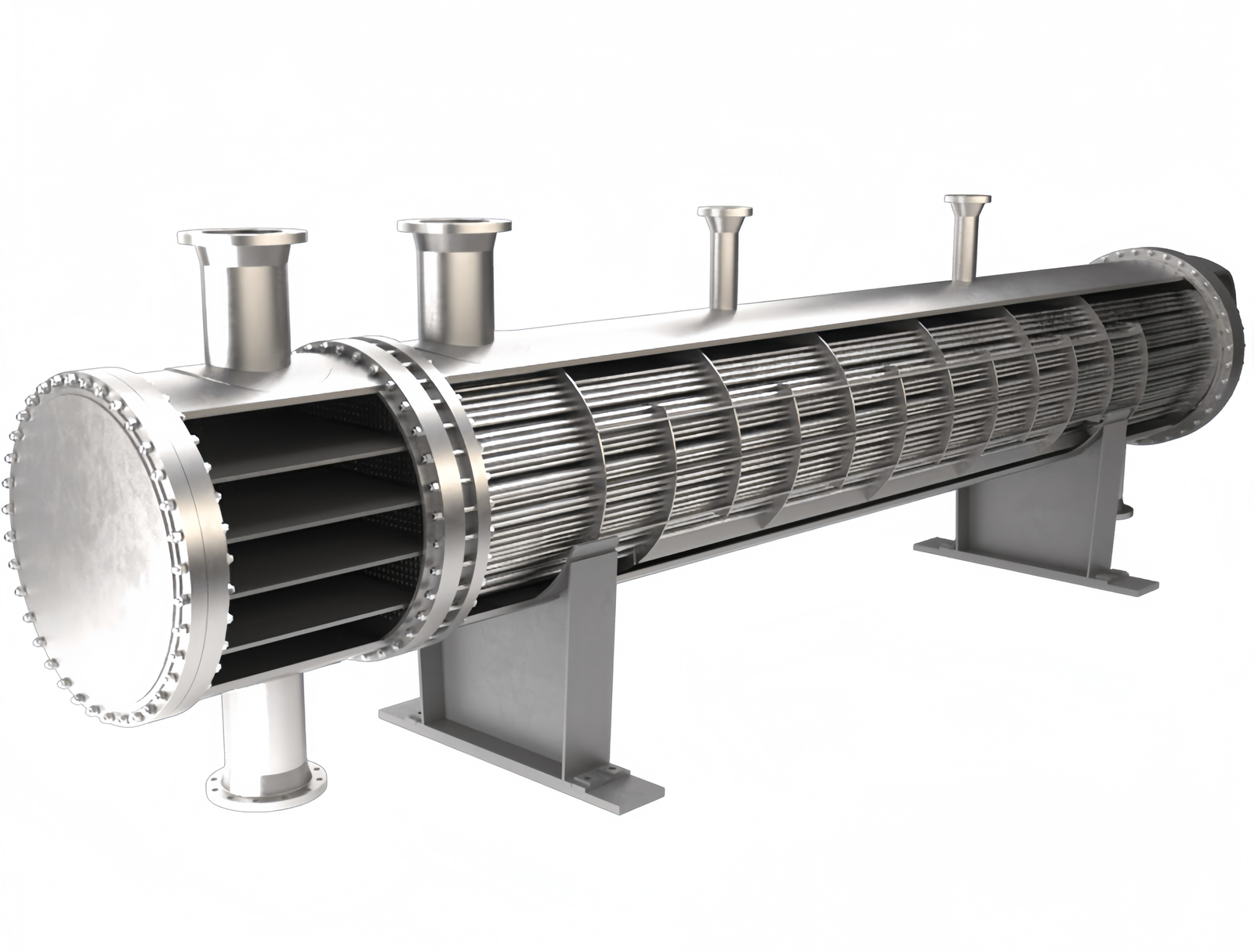

This guide shares proven strategies to maximize energy efficiency in shell and tube heat exchangers, plate heat exchangers, and air-cooled units.

For related topics, see 5 Proven Ways to Improve Heat Exchanger Efficiency, Shell and Tube Heat Exchanger Design Considerations, and Heat Exchanger Maintenance Checklist.

2. Optimize Heat Exchanger Design

- Correct sizing prevents underperformance or excessive pressure drops—see How to Size a Shell and Tube Heat Exchanger.

- Select materials with high thermal conductivity and corrosion resistance; review Heat Exchanger Tube Materials for guidance.

3. Prevent Fouling and Scaling

Fouling reduces heat transfer efficiency and increases energy demand.

- Implement regular cleaning schedules—see 7 Effective Ways to Prevent Fouling in Heat Exchangers.

- Use filtration systems to remove particulates from process fluids.

- Consider coatings or material upgrades for high-fouling environments.

- For step-by-step fouling control, follow this prevention guide. Then apply fundamental tactics to improve heat exchanger efficiency and sustain results with a rigorous maintenance checklist.

4. Recover Waste Heat

Install additional exchangers or integrate with process streams to capture and reuse heat that would otherwise be wasted. This is especially effective in oil refineries, food processing, and chemical plants.

5. Improve Flow Arrangements

- Use counterflow configurations to maximize temperature differentials.

- Adjust baffle spacing in shell and tube designs to enhance turbulence without causing excessive pressure drop.

6. Maintain Proper Operating Conditions

- Monitor inlet and outlet temperatures to identify performance losses.

- Keep flow rates within design parameters to avoid erosion or vibration damage.

- Ensure water chemistry is within specified limits to prevent corrosion.

7. Upgrade Tube Materials

Switching to duplex stainless steel or titanium tubes in seawater-cooled applications can improve heat transfer stability and reduce cleaning frequency, resulting in long-term energy savings. See Best Material for Seawater Heat Exchanger.

8. Real-World Example

A beverage manufacturer upgraded their plate heat exchangers with optimized plate patterns and switched to duplex stainless steel tubing in auxiliary shell and tube units. This change reduced annual energy consumption by 12% and cut downtime by 20%.

9. Conclusion

Implementing energy-saving measures in industrial heat exchangers delivers both environmental and financial benefits. Whether through better design, preventive maintenance, or material upgrades, every efficiency improvement contributes to lower operational costs.

Explore our related guides for deeper insights:

Contact DLSS

At DLSS, we manufacture high-quality stainless steel tubes for heat exchanger applications, ensuring optimal heat transfer, corrosion resistance, and long service life.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Related Reading