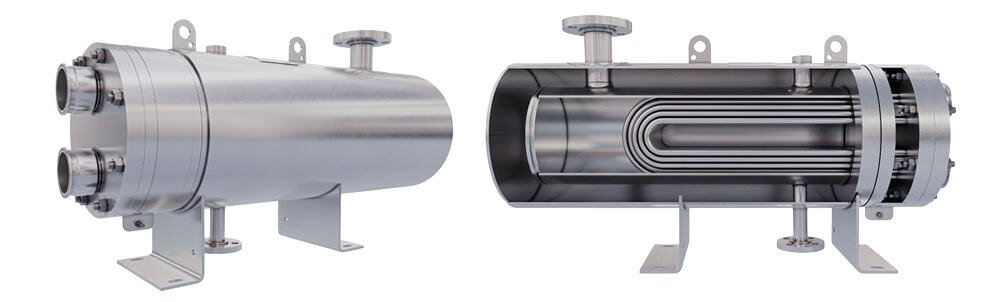

1. Introduction – Heat Exchanger Troubleshooting

A heat exchanger is a critical component in many industrial systems, and any performance issue can lead to reduced efficiency, higher operating costs, or even production downtime. This heat exchanger troubleshooting guide covers the most common problems, their likely causes, and practical solutions to get your system back on track.

For related topics, see 5 Proven Ways to Improve Heat Exchanger Efficiency, 7 Effective Ways to Prevent Fouling in Heat Exchangers, Best Material for Seawater Heat Exchanger, Heat Exchanger Maintenance Checklist, and Shell and Tube Heat Exchanger Design Considerations.

2. Common Heat Exchanger Problems and Solutions

1. Reduced Heat Transfer Efficiency

Possible Causes:

- Fouling or scaling on tube or plate surfaces

- Air or gas pockets inside the unit

- Incorrect flow arrangement

Solutions:

- Perform cleaning based on fouling type; see 7 Effective Ways to Prevent Fouling in Heat Exchangers

- Vent trapped gases from the exchanger

- Verify and adjust flow configuration

2. High Pressure Drop

Possible Causes:

- Blockage from debris or fouling

- Excessive flow velocity

- Damaged baffles or tube restrictions

- After restoring performance, lock in the gains by preventing fouling and applying additional energy-saving measures. For fundamentals, revisit efficiency improvement best practices.

Solutions:

- Clean tubes or plates to remove blockages

- Reduce flow rate within design limits

- Inspect and replace damaged baffles

3. Tube or Plate Leaks

Possible Causes:

- Corrosion or erosion damage

- Thermal stress cracking

- Gasket failure

Solutions:

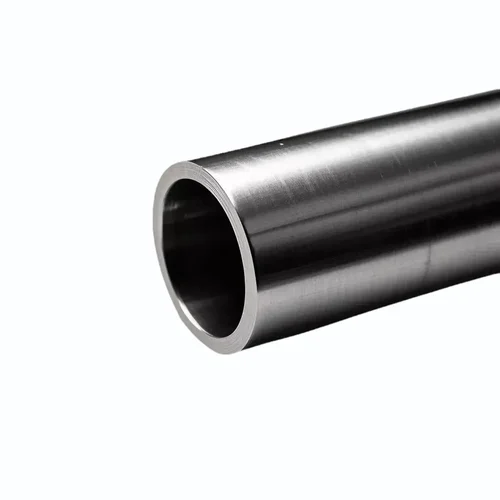

- Replace damaged tubes with corrosion-resistant materials such as duplex stainless steel or titanium

- Upgrade gaskets to compatible materials

- Review system operation to reduce thermal cycling

4. Unusual Vibrations or Noise

Possible Causes:

- Flow-induced vibration from high velocity

- Loose tube supports or baffles

- Cavitation in pumps feeding the exchanger

Solutions:

- Reduce flow velocity to design range

- Tighten or replace supports and baffles

- Check pump operation and NPSH requirements

5. Frequent Maintenance Requirements

Possible Causes:

- Inappropriate material selection for service environment

- Poor water treatment

- Inadequate design for cleaning access

Solutions:

- Upgrade to more suitable tube material; see Best Material for Seawater Heat Exchanger

- Improve water treatment program

- Modify design for easier maintenance access

3. Preventive Measures to Avoid Recurring Issues

- Follow a regular inspection and cleaning schedule; see Heat Exchanger Maintenance Checklist

- Monitor operating data for early warning signs

- Select materials and designs suited to your specific process fluids

- Train operators on best practices for start-up and shutdown

4. Real-World Example

A food processing facility experienced frequent pressure drop increases in their shell and tube heat exchangers. After switching to smooth, pickled duplex stainless steel tubes and improving water filtration, fouling incidents dropped by 70%, and maintenance intervals doubled from 6 months to 12 months.

5. Conclusion

Heat exchanger troubleshooting starts with identifying the root cause of the issue and implementing targeted solutions. By understanding common problems and preventive measures, you can maintain high efficiency, reduce downtime, and extend equipment life.

For more detailed design and maintenance strategies, explore our related articles:

Contact DLSS

At DLSS, we manufacture high-quality stainless steel tubes for heat exchanger applications, ensuring optimal heat transfer, corrosion resistance, and long service life.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Related Reading