1. Introduction – Heat Exchanger Maintenance Checklist

Following a structured heat exchanger maintenance checklist is the most effective way to keep your equipment running efficiently, avoid costly breakdowns, and extend service life.

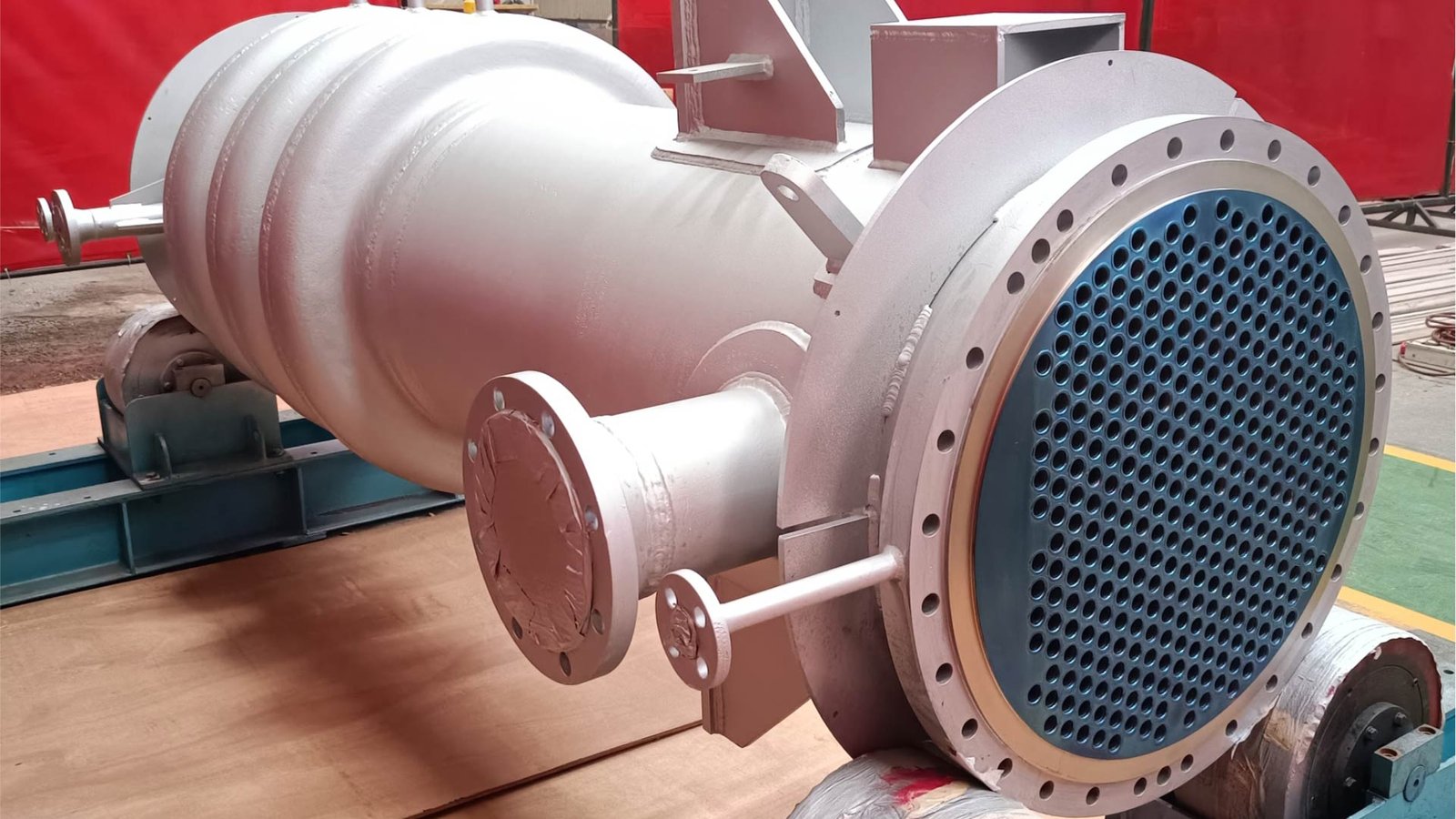

Whether you operate a shell and tube heat exchanger, a plate heat exchanger, or an air-cooled model, regular preventive maintenance ensures consistent heat transfer performance and minimizes unplanned downtime.

For related optimization strategies, see 5 Proven Ways to Improve Heat Exchanger Efficiency, 7 Effective Ways to Prevent Fouling in Heat Exchangers, and Best Material for Seawater Heat Exchanger.

2. Why Maintenance Is Critical for Heat Exchangers

Neglecting maintenance can lead to:

- Reduced thermal efficiency due to fouling or scaling

- Higher energy consumption

- Increased risk of leaks or tube failures

- Shortened equipment lifespan

- Expensive emergency repairs

According to ASME guidelines, implementing a preventive maintenance program can extend the life of a heat exchanger by up to 30%.

3. Heat Exchanger Maintenance Checklist

1. Visual Inspection

- Check for leaks, corrosion spots, or unusual vibrations.

- Inspect gaskets, seals, and bolts for wear or damage.

2. Monitor Operating Parameters

- Record inlet/outlet temperatures and pressure drops.

- Compare current data with baseline performance to detect early issues.

3. Clean Heat Transfer Surfaces

- Use chemical cleaning for scale removal.

- Apply mechanical brushing or hydro-jet cleaning for debris and biofouling.

- Refer to 7 Effective Ways to Prevent Fouling in Heat Exchangers for long-term prevention strategies.

- To minimize future cleaning, apply best practices to prevent heat exchanger fouling, and track energy savings using these energy-saving tips.

4. Water Quality Management

- Test for pH, hardness, and chloride content regularly.

- Install filtration systems to reduce particulate contamination.

5. Lubrication and Moving Parts Maintenance

- Lubricate any rotating or sliding components, such as expansion joints or valve linkages.

6. Non-Destructive Testing (NDT)

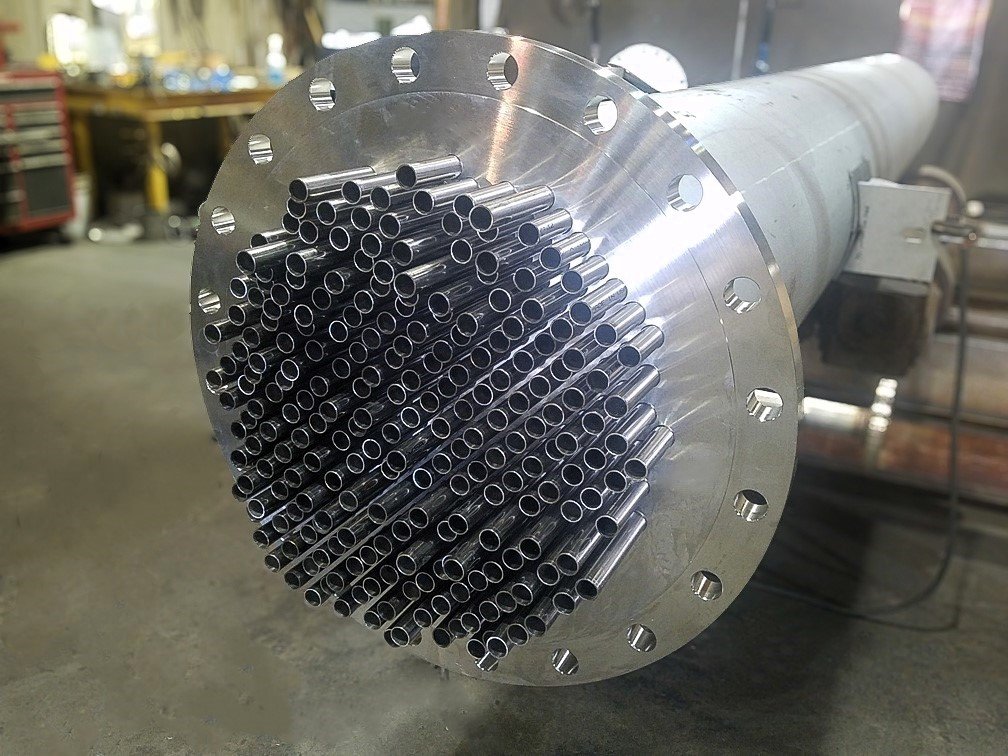

- Perform ultrasonic thickness testing or eddy current inspections to detect hidden tube wall loss.

7. Documentation

- Keep detailed maintenance logs, inspection reports, and cleaning records.

- Use historical data to optimize maintenance intervals.

4. Maintenance Frequency Recommendations

- Monthly: Visual inspections and parameter checks

- Quarterly: Water quality testing and minor cleaning if required

- Annually: Full inspection, complete cleaning, and NDT testing

The actual schedule should be adapted to your operating environment, fluid type, and production demands.

5. Real-World Example

A power plant implemented this checklist and switched to duplex stainless steel tubes for their seawater-cooled exchangers. As a result, fouling was reduced by 40%, cleaning frequency was cut in half, and tube life expectancy increased from 8 years to 12 years.

6. Conclusion

A consistent heat exchanger maintenance checklist improves thermal performance, extends service life, and lowers overall operating costs. By combining regular inspections, proactive cleaning, and high-quality materials, you can ensure optimal performance for years to come.

For more insights, read 5 Proven Ways to Improve Heat Exchanger Efficiency and Best Material for Seawater Heat Exchanger.

Contact DLSS

At DLSS, we manufacture high-quality stainless steel tubes for heat exchanger applications, ensuring optimal heat transfer, corrosion resistance, and long service life.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Related Reading

- Best Material for Seawater Heat Exchanger

- Heat Exchanger Troubleshooting Guide

- Improve Heat Exchanger Efficiency