Meta Description:

Explore global market trends, key drivers, and regional opportunities shaping the future of stainless steel seamless pipe demand between 2025 and 2030.

Introduction

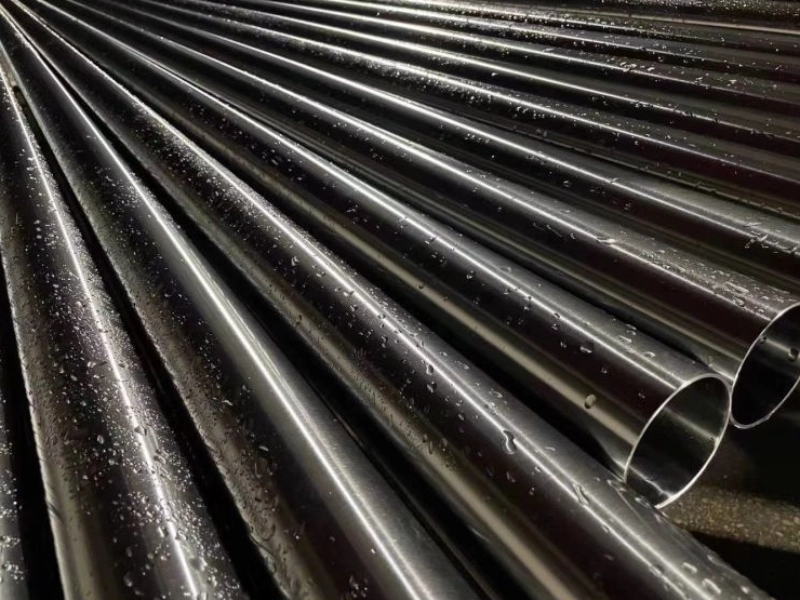

The stainless steel seamless pipe industry is entering a new growth phase driven by infrastructure investments, energy transition, and decarbonization.

From oil & gas to clean energy, seamless pipes play a vital role in delivering strength, corrosion resistance, and reliability across mission-critical systems.

In this article, we provide an up-to-date view of global market trends, highlight regional insights, and discuss the top industries driving demand through 2030.

Global Market Size and Growth Forecast

According to GlobeNewswire, the global stainless steel seamless pipes market was valued at USD 3.9 billion in 2025 and is expected to reach USD 5.15 billion by 2030, growing at a CAGR of 5.6%.

Key growth drivers:

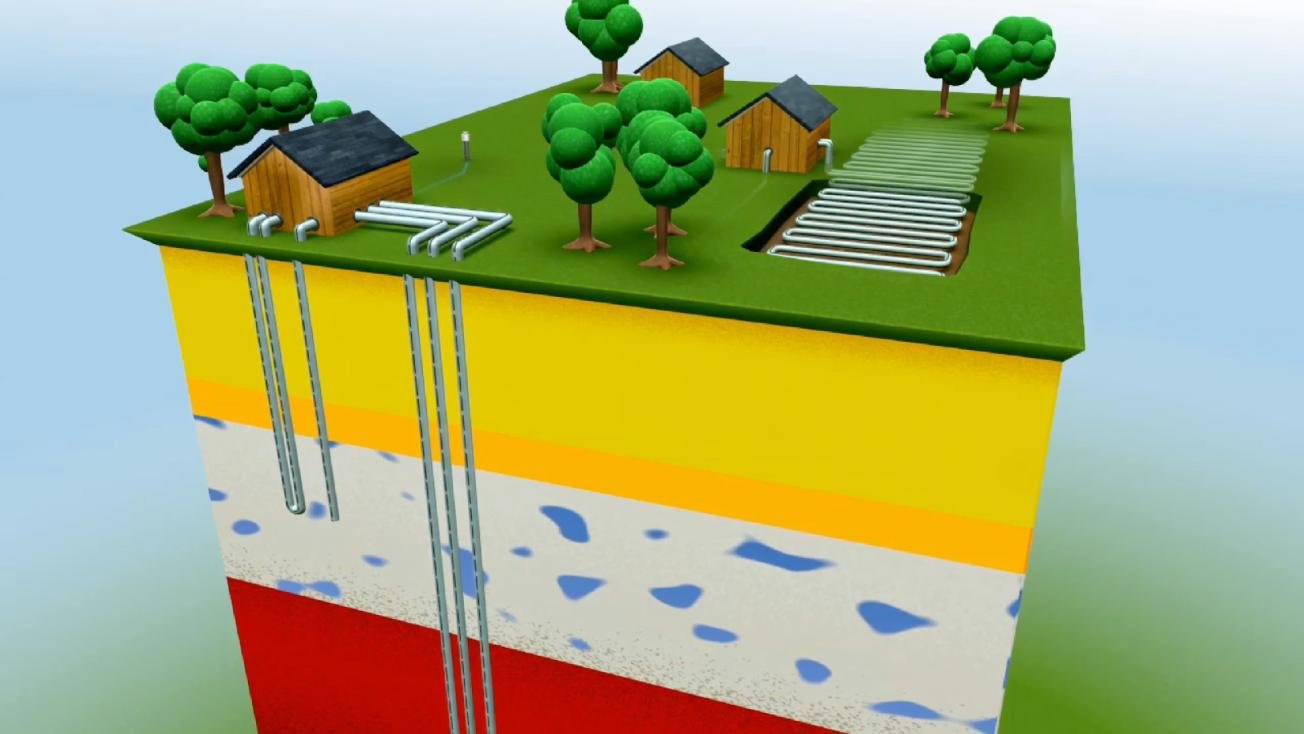

- Increasing demand in refinery upgrades, petrochemical expansions, and gas transmission projects

- Adoption of stainless steel in hydrogen and carbon capture infrastructure

- Expansion of offshore wind and geothermal systems

- Focus on high-efficiency, low-maintenance industrial equipment

Leading Regions and Markets

Asia-Pacific

- Dominated by China and India, which together account for over 50% of global consumption

- Driven by mega projects in power generation, chemical processing, and urban infrastructure

Middle East

- Significant demand from desalination plants, oil & gas EPC projects, and LNG export terminals

- Clients often require NACE MR0175-certified tubes

Europe

- Strong focus on renewables, especially green hydrogen, district heating, and waste-to-energy plants

- Preference for tubes with EN 10204 3.2 certification, tested by TÜV, BV, or SGS

South America

- Growing investments in biofuels, refining, and mining in Brazil, Argentina, and Chile

- Demand for high-grade TP316L, TP347H, and Duplex 2205

Industry Segments Driving Demand

| Sector | Key Pipe Characteristics |

|---|---|

| Oil & Gas | Sour gas resistance, NACE compliance, thick wall |

| Petrochemicals | TP316L/317L, high purity & pressure rated |

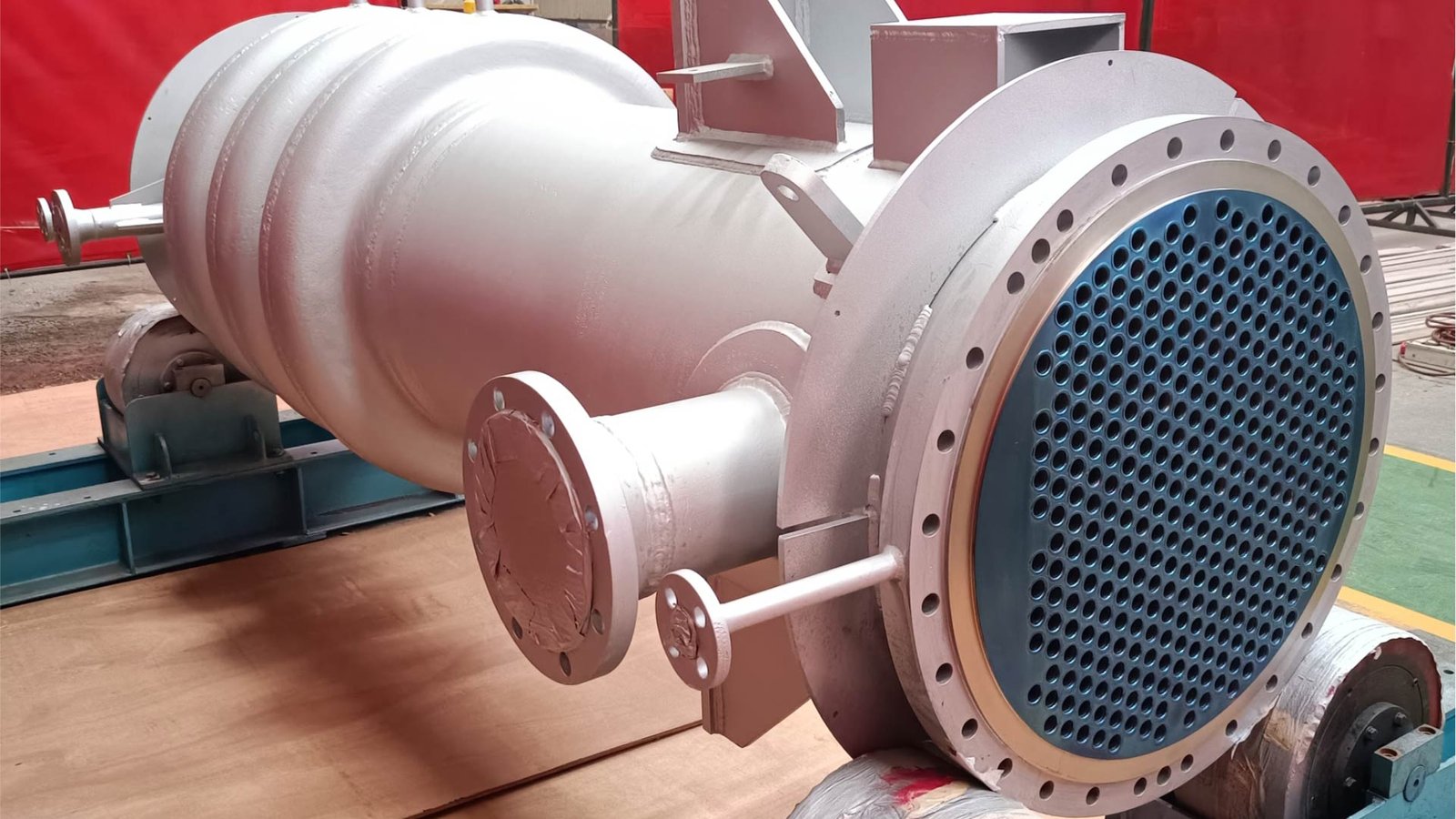

| Power Generation | Superheater/boiler tubes, TP347H, Alloy 625 |

| Renewable Energy | Duplex for seawater, Incoloy for high-temp HX |

| Pharma & Food | BA/EP tubes, ASTM A270-S2, ID polished |

Technology and Quality Trends

- Growing preference for pickled or electropolished seamless tubes

- Increased use of automated testing (PMI, EC, UT)

- Integration of digital MTC records and traceability systems

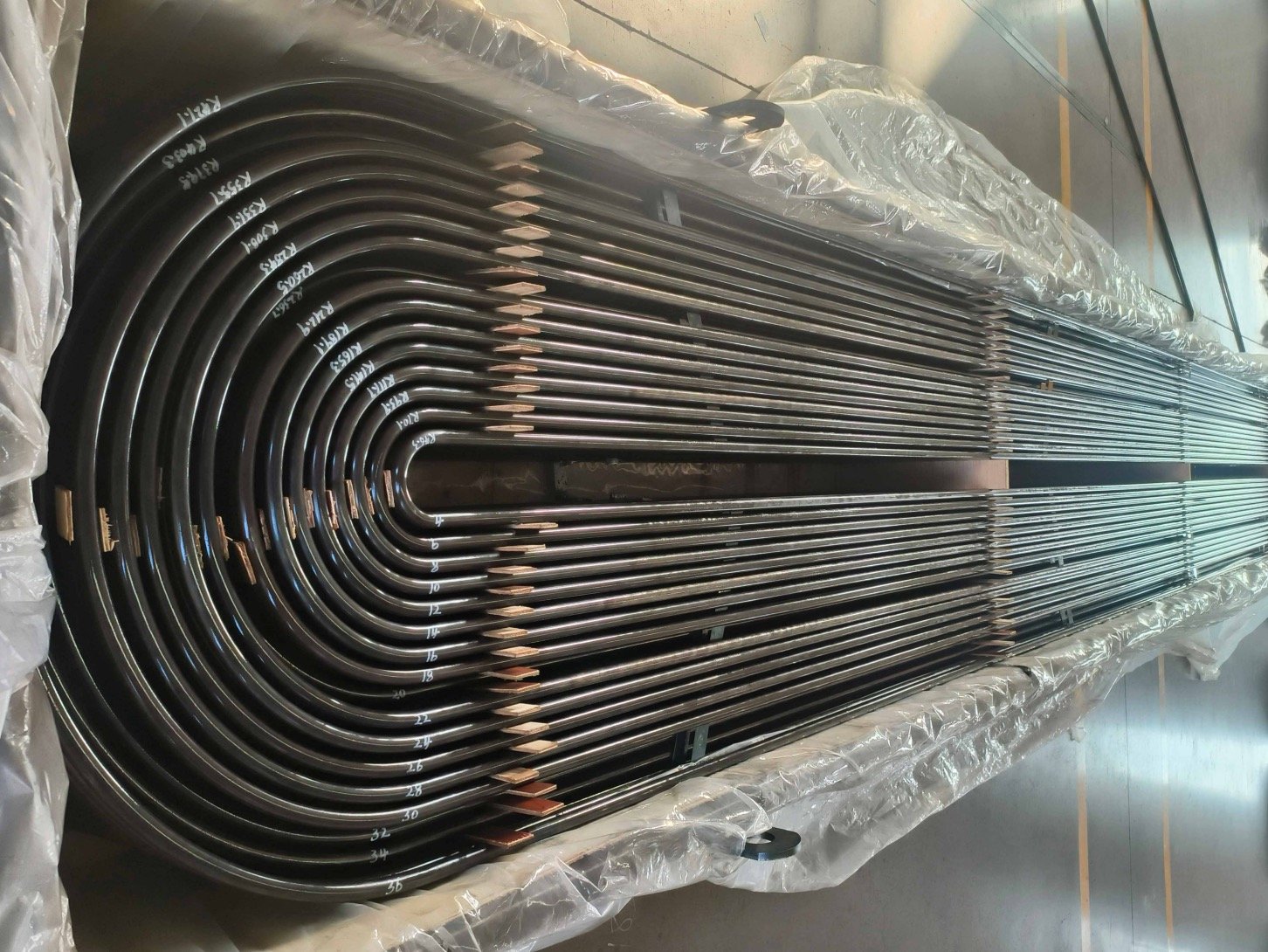

- Demand for custom lengths and U-bend tubes for heat exchangers

Frequently Asked Questions (FAQ)

Q1: What is driving the stainless seamless pipe market in 2025?

Primarily growth in oil & gas, energy transition, and industrial modernization.

Q2: Which grades are in highest demand?

TP316L, TP347H, Duplex 2205, and special alloys like Incoloy 825 and Alloy 625.

Q3: Are 3.2 certified pipes becoming standard?

Yes, especially in Europe, South America, and government EPC projects.

Q4: How is DLSS supporting this growth?

DLSS supplies project-specific, standard-compliant seamless tubes across 40+ countries with flexible production and third-party inspections.

Conclusion

The stainless steel seamless pipe market is set to expand steadily over the next five years, fueled by energy investment, industrial upgrades, and global decarbonization goals.

By choosing a certified and experienced supplier like DLSS, project managers can secure reliable, traceable, and performance-driven pipe solutions ready for tomorrow’s demands.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com