Meta Description:

Discover how to meet NACE MR0175/ISO 15156 compliance when sourcing stainless steel seamless tubes for sour service. Learn about materials, testing, certifications, and supplier selection.

Introduction

Sour gas environments—containing hydrogen sulfide (H₂S)—pose one of the greatest challenges for stainless steel tubes in the oil and gas industry. The presence of H₂S increases the risk of sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC), which can lead to catastrophic failures if materials are not selected and tested properly.

To mitigate these risks, the industry relies on NACE MR0175, also known internationally as ISO 15156. This standard specifies material requirements for H₂S-containing environments in oilfield equipment.

This guide provides practical steps for ensuring compliance when sourcing seamless stainless steel tubes for sour service.

What Is NACE MR0175 / ISO 15156?

- A material qualification standard created by NACE International

- Specifies which alloys are resistant to SSC, HIC, and SCC in H₂S-rich environments

- Applicable to equipment used in upstream, midstream, and offshore operations

- Defines hardness limits, microstructure requirements, and testing methods

Official resource: NACE MR0175 / ISO 15156 overview

Which Stainless Steel Grades Are Compliant?

NACE MR0175 only approves certain grades under specific conditions. Here are commonly used compliant grades:

| Grade | NACE Acceptance | Notes |

|---|---|---|

| 316L / TP316L | Yes | Max hardness: 22 HRC (250 HV) |

| Duplex 2205 | Yes | Requires PREN ≥ 34, ferrite < 70% |

| Super Duplex S32750/S32760 | Yes | Excellent resistance, lower impact temp |

| Incoloy 825 | Yes | Used in subsea, aggressive sour service |

| Alloy 20 (UNS N08020) | Yes | Often chosen for sulfur-rich media |

| 904L / 254SMO | Conditional | Must meet hardness and testing limits |

Key Requirements for Compliance

Hardness Control

- Austenitic stainless steel: typically ≤ 22 HRC

- Duplex stainless steel: ≤ 28 HRC (ASTM E18 or ISO 6508-1)

- Requires controlled heat treatment and testing

Microstructure Validation

- Duplex tubes must show balanced ferrite-austenite structure

- No sigma phase or harmful intermetallics

Testing Protocols

- SSC test (TM0177) for tensile stress in H₂S

- HIC test (TM0284) for plate or heavy-walled tubes

- Many end users (e.g., Aramco, ADNOC) mandate 100% UT and PT in addition

Documentation

- EN 10204 3.1 / 3.2 MTCs clearly stating:

- Material grade

- Hardness values

- Heat treatment method

- Compliance note: “NACE MR0175 Compliant”

Best Practices for Buyers

Ask the Right Questions

- Is the alloy grade NACE-approved for your pressure/temperature range?

- Was the material tested for hardness and microstructure?

- Is the supplier ISO 9001 or PED certified?

- Can they issue 3.2 certification with NACE clause?

Work with Prequalified Suppliers

DLSS has delivered stainless tubes compliant with NACE MR0175 to:

- Offshore FPSO platforms in Malaysia

- Oil refineries in Iran and the UAE

- Subsea equipment in Norway

- Sour service heat exchangers in Qatar and Oman

Browse DNV-approved material list to cross-reference supplier qualifications.

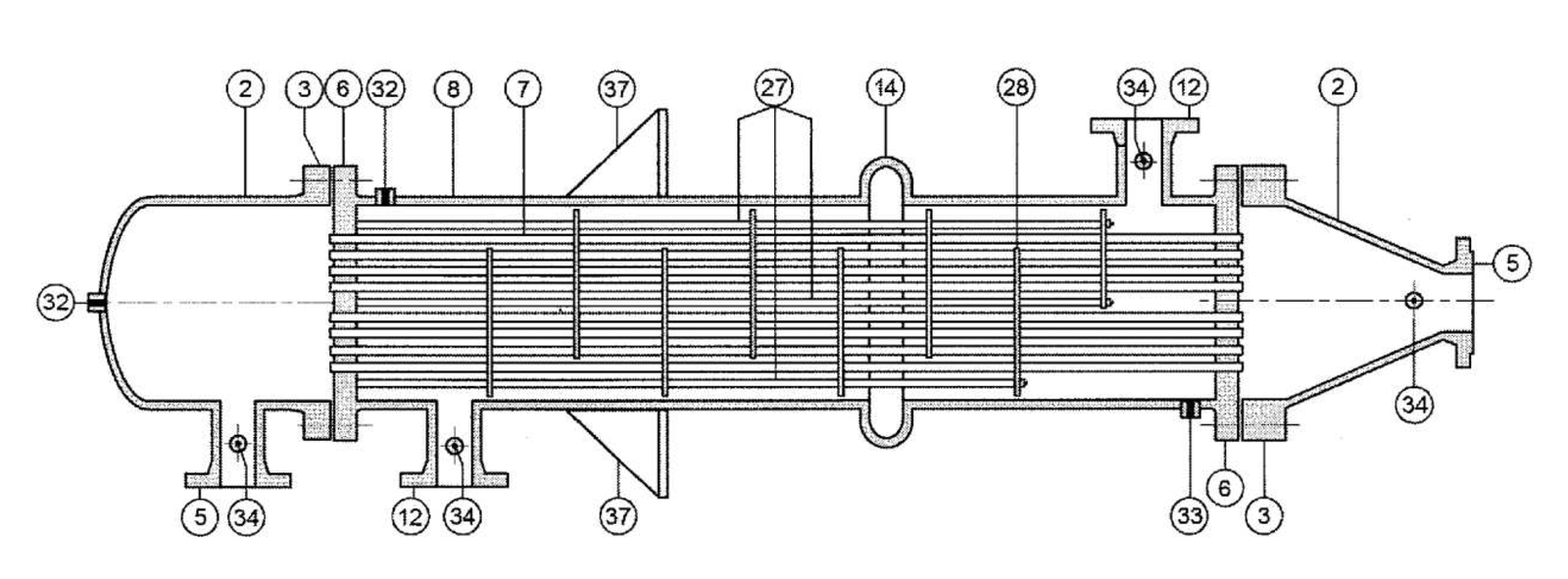

Case Study: NACE Tubes for a Middle East Gas Field

A client in Oman required TP316L seamless U-bend tubes for a sour gas heat exchanger. The project required:

- Hardness ≤ 22 HRC

- Grain size ≥ ASTM No. 6

- 100% Eddy Current Testing

- 3.2 certificate with NACE clause

DLSS supplied the entire bundle with BV inspection, ensuring complete compliance and successful installation.

Conclusion

NACE MR0175 compliance is more than a checkbox—it’s a safeguard for critical oil and gas infrastructure. To avoid project delays, equipment failure, or liability:

- Know which stainless grades are approved

- Verify heat treatment and hardness results

- Demand traceable MTCs with testing data

- Choose experienced manufacturers like DLSS

DLSS Capabilities for NACE-Compliant Tubes

- Seamless stainless tubes: TP316L, Duplex 2205, Incoloy 825

- U-bend, bright annealed, pickled, and polished options

- NDT (UT, ECT), hardness test, grain size test

- 3.1/3.2 certificates with NACE compliance

Contact Us

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help qualifying stainless tubes for NACE MR0175 service? DLSS is ready to assist with material selection, inspection support, and global supply logistics.