Meta Description:

Discover the key differences between NACE MR0175 and MR0103. Learn how each applies to stainless steel tubes used in sour service and refinery environments.

Introduction

When sourcing stainless steel tubes for corrosive environments, especially those involving hydrogen sulfide (H₂S), two international standards are frequently cited:

- NACE MR0175 (ISO 15156)

- NACE MR0103

While both relate to sulfide stress cracking (SSC) resistance, they apply to different industries and conditions. Misinterpreting their scope can lead to rejected materials or premature failures.

This article clarifies how these standards differ and what they mean for your procurement decisions—especially for seamless and welded tubes used in oil & gas and refinery sectors.

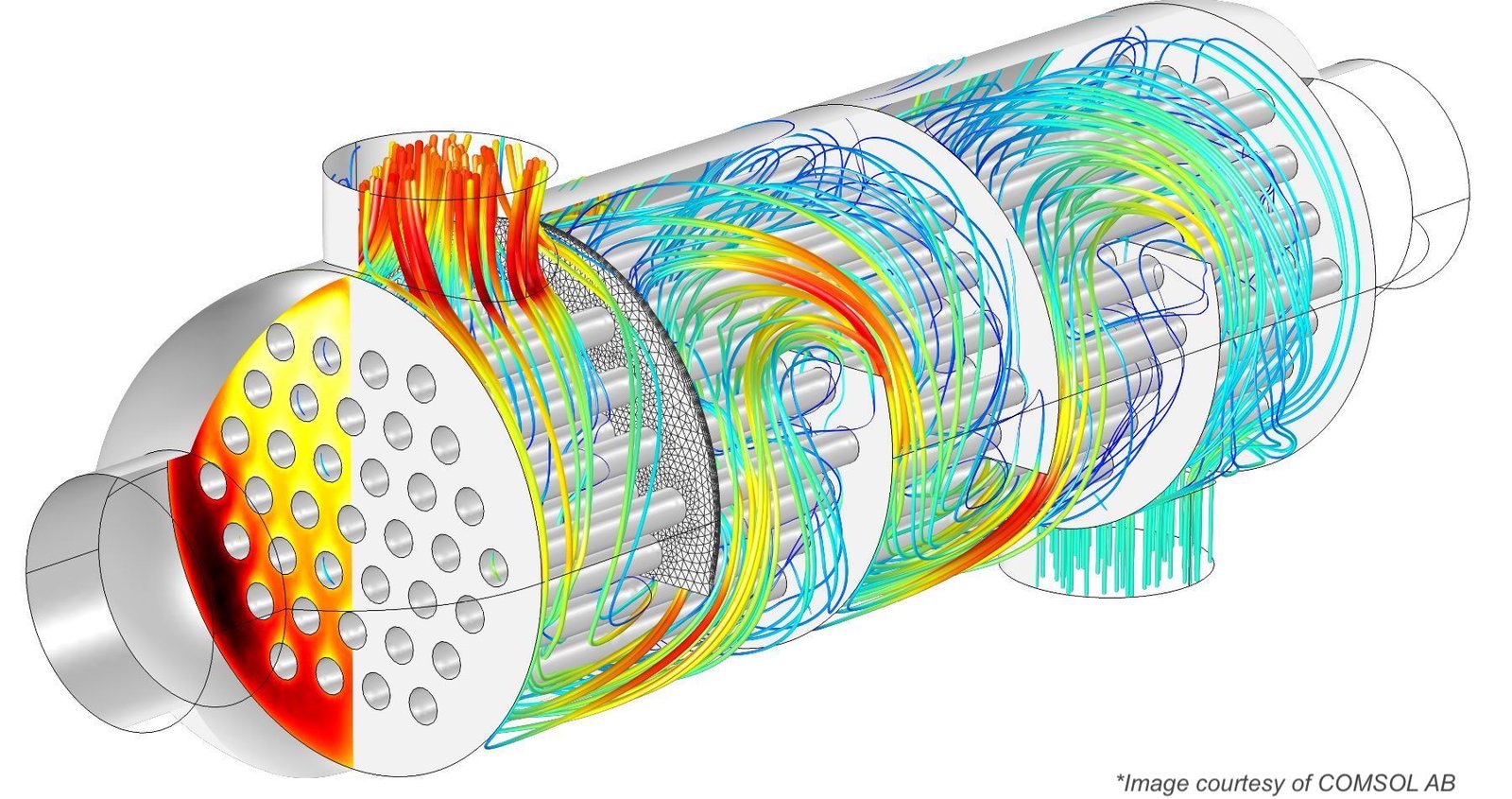

What Is NACE MR0175 (ISO 15156)?

Originally developed by the National Association of Corrosion Engineers (NACE), MR0175 is now incorporated into ISO 15156. It provides guidelines for material selection in upstream oil & gas production systems where H₂S may be present.

Applies To:

- Wellheads

- Offshore platforms

- Downhole equipment

- Subsea piping

Key Features:

- Requires specific hardness limits (e.g., ≤22 HRC for austenitic stainless)

- Mandates microstructure control (e.g., no sensitization, grain size range)

- Material must be qualified via lab testing or historical field data

- Not applicable to atmospheric refinery conditions

For full details, refer to ISO 15156-3 standard overview

What Is NACE MR0103?

MR0103 was developed for refining and chemical processing plants, where sour service occurs under atmospheric or low-pressure conditions (vs. high-pressure wells).

Applies To:

- Desulfurization units

- Hydrotreaters

- Amine regeneration columns

- Overhead lines in distillation towers

Key Features:

- Includes hardness limits similar to MR0175

- Focuses on fabrication practices, weld heat-affected zones (HAZ), and stress relief

- Allows certain materials not approved under MR0175 (e.g., soft-tempered 304L)

For deeper reading, see NACE International’s MR0103 page

Key Differences: MR0175 vs MR0103

| Aspect | NACE MR0175 / ISO 15156 | NACE MR0103 |

|---|---|---|

| Industry Focus | Oil & Gas (Upstream) | Refining & Petrochemical |

| Pressure Condition | High-pressure (subsurface systems) | Atmospheric or low-pressure |

| Governing Body | ISO (via NACE) | NACE International |

| Certification Required? | Usually required for EPC projects | Often referenced in refinery specs |

| Hardness Limitations | Strict (≤22 HRC or ≤250 HV) | Similar limits, more lenient welding |

| Testing Requirement | Historical field data or lab proof | May be waived with approved process |

| ISO Status | Yes (ISO 15156) | No (NACE-only document) |

Why It Matters for Tube Procurement

When a customer or EPC contract specifies NACE compliance:

- Don’t assume MR0175 and MR0103 are interchangeable

- Check the operating pressure and location of the system

- Request MTC or lab reports verifying SSC resistance

At DLSS, we supply stainless and alloy tubes that comply with both MR0175 and MR0103 standards, based on intended use.

Materials Commonly Qualified Under Each Standard

| Material Grade | MR0175 | MR0103 |

|---|---|---|

| TP316L (Low C, BA) | Yes (limited) | Yes |

| TP317L | Yes | Yes |

| Incoloy 825 | Yes (full compliance) | Yes |

| 254 SMO | Yes (PREN >40) | Yes |

| TP304L | Rare | Often allowed |

For reference material, visit Sandvik’s sour service material datasheets

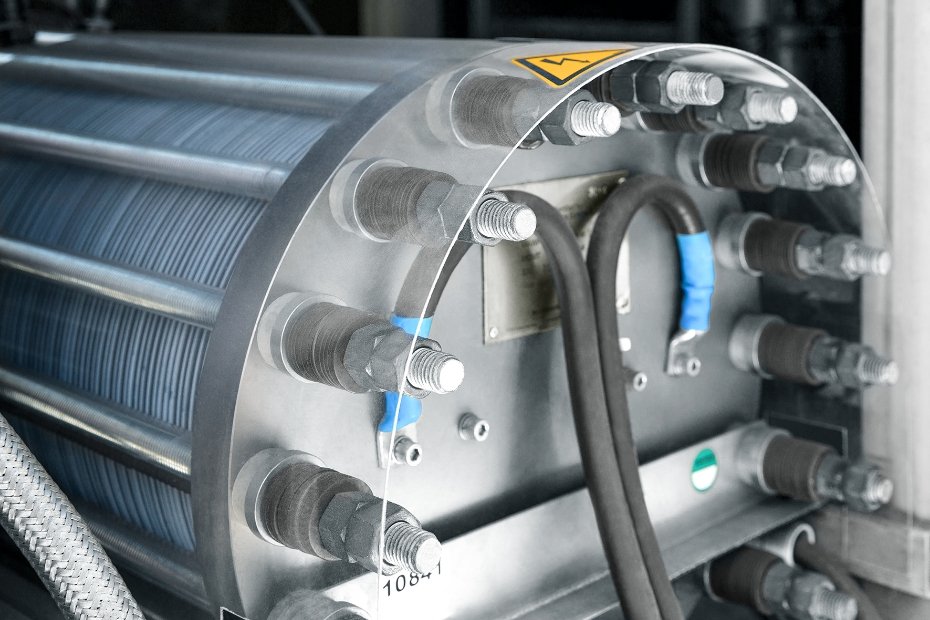

DLSS Support for NACE-Compliant Tubes

We offer:

- Full traceability with EN 10204 3.1 / 3.2 certificates

- Controlled hardness and grain size reports

- PMI and intergranular corrosion testing

- Experience with petrochemical EPC inspections (TUV, SGS, BV)

Contact us to specify your NACE-compliant tube supply with zero compliance risk.

Conclusion

NACE MR0175 and MR0103 are not interchangeable, but they’re both crucial for preventing sulfide stress cracking in sour service.

- Use MR0175 for upstream/high-pressure environments

- Use MR0103 for atmospheric refinery systems

DLSS can guide you through material selection, documentation, and third-party compliance to ensure safe, efficient, and certifiable tube supply.

Contact DLSS for NACE-Compliant Tubes

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let’s build a corrosion-resistant future—standard by standard.