When selecting spiral finned tube vs extruded finned tube for a heat exchanger, engineers must weigh performance, durability, and operating costs. Both fin types enhance heat transfer, but their differences can significantly affect long-term efficiency.

If you’re new to finned tubes, start with What is a Finned Tube and How It Improves Heat Exchanger Efficiency. For material-specific guidance, see our Finned Tube Material Selection Guide.

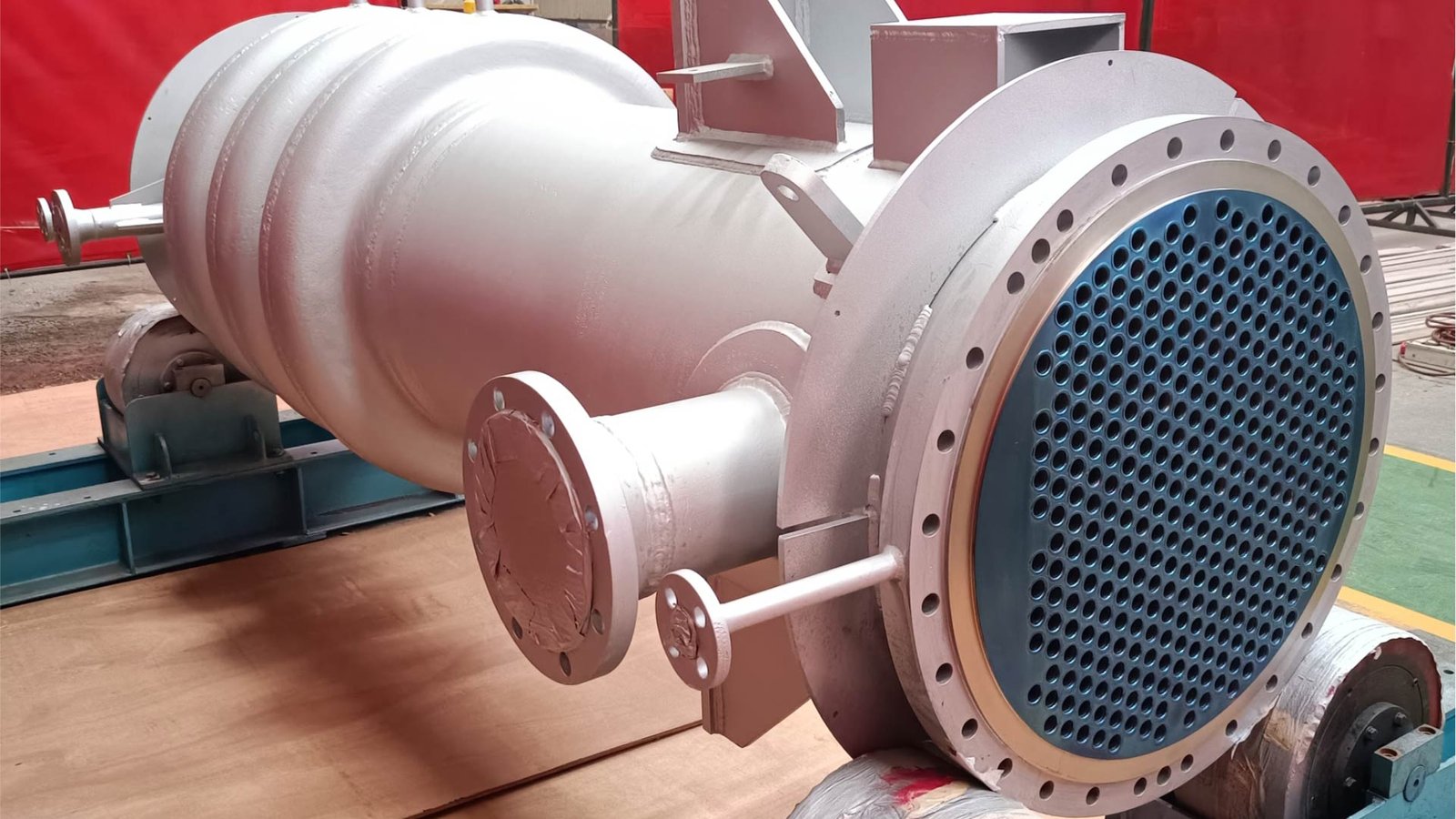

1. What is a Spiral Finned Tube?

A spiral finned tube is made by helically winding a metal strip (often carbon steel or stainless steel) around the base tube and welding it for a strong mechanical bond.

Advantages:

- High mechanical strength for high-temperature gases

- Cost-effective for large heat exchanger projects

- Excellent for boilers, petrochemical plants, and industrial heaters

Limitations:

- Lower corrosion resistance than extruded fins

- Potential for fouling in harsh environments

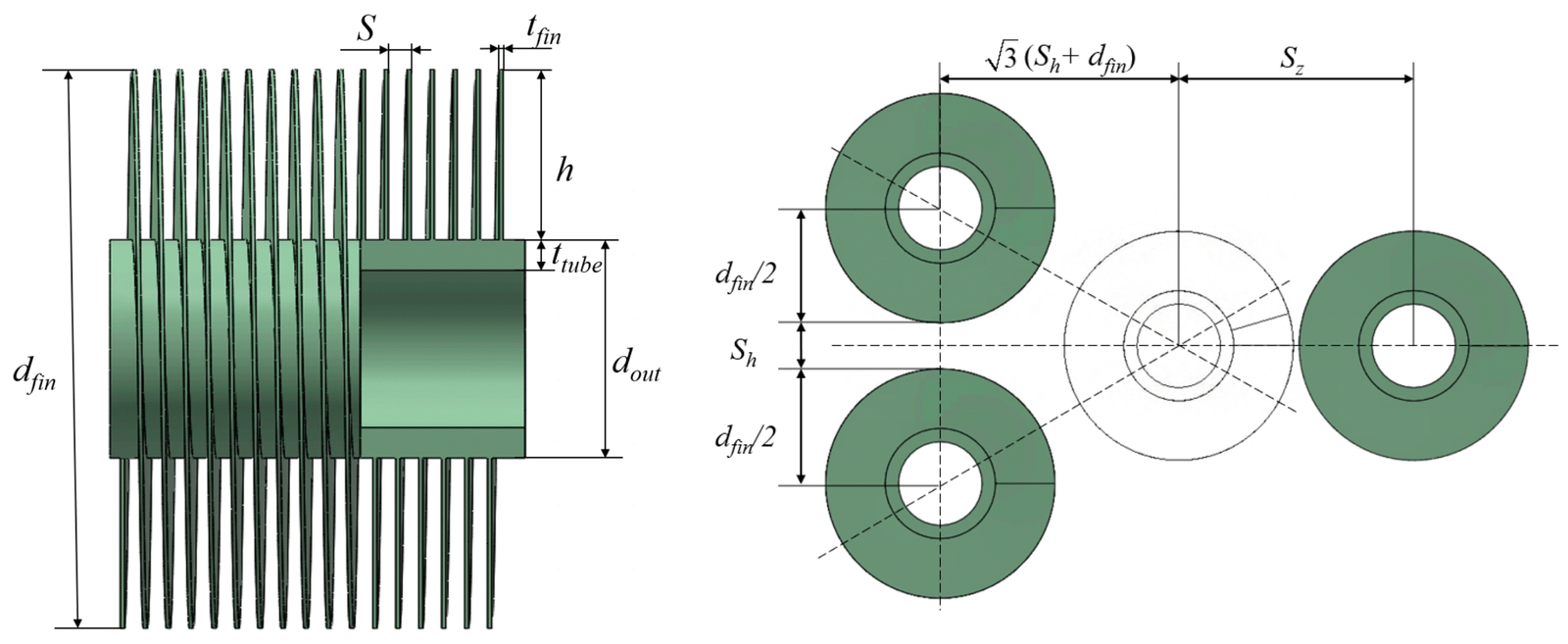

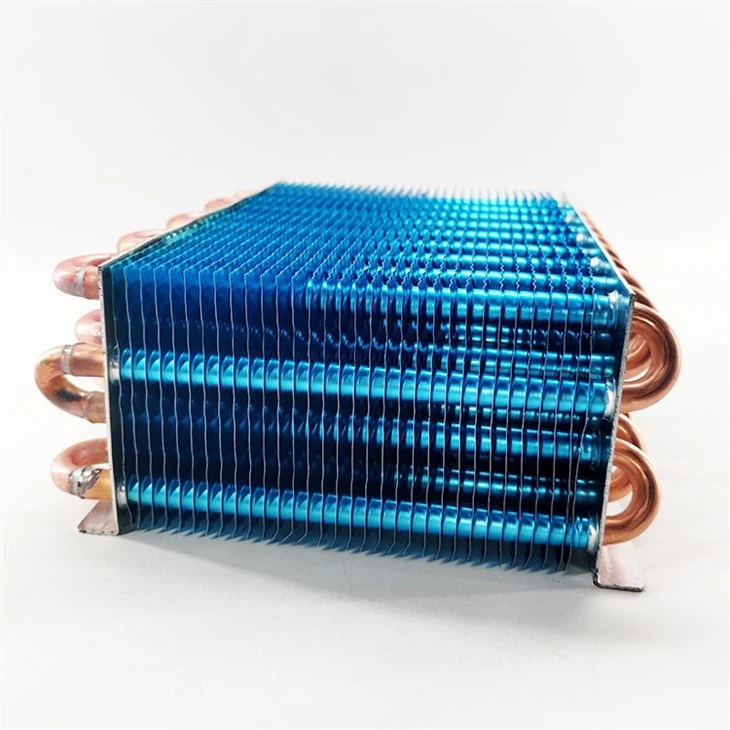

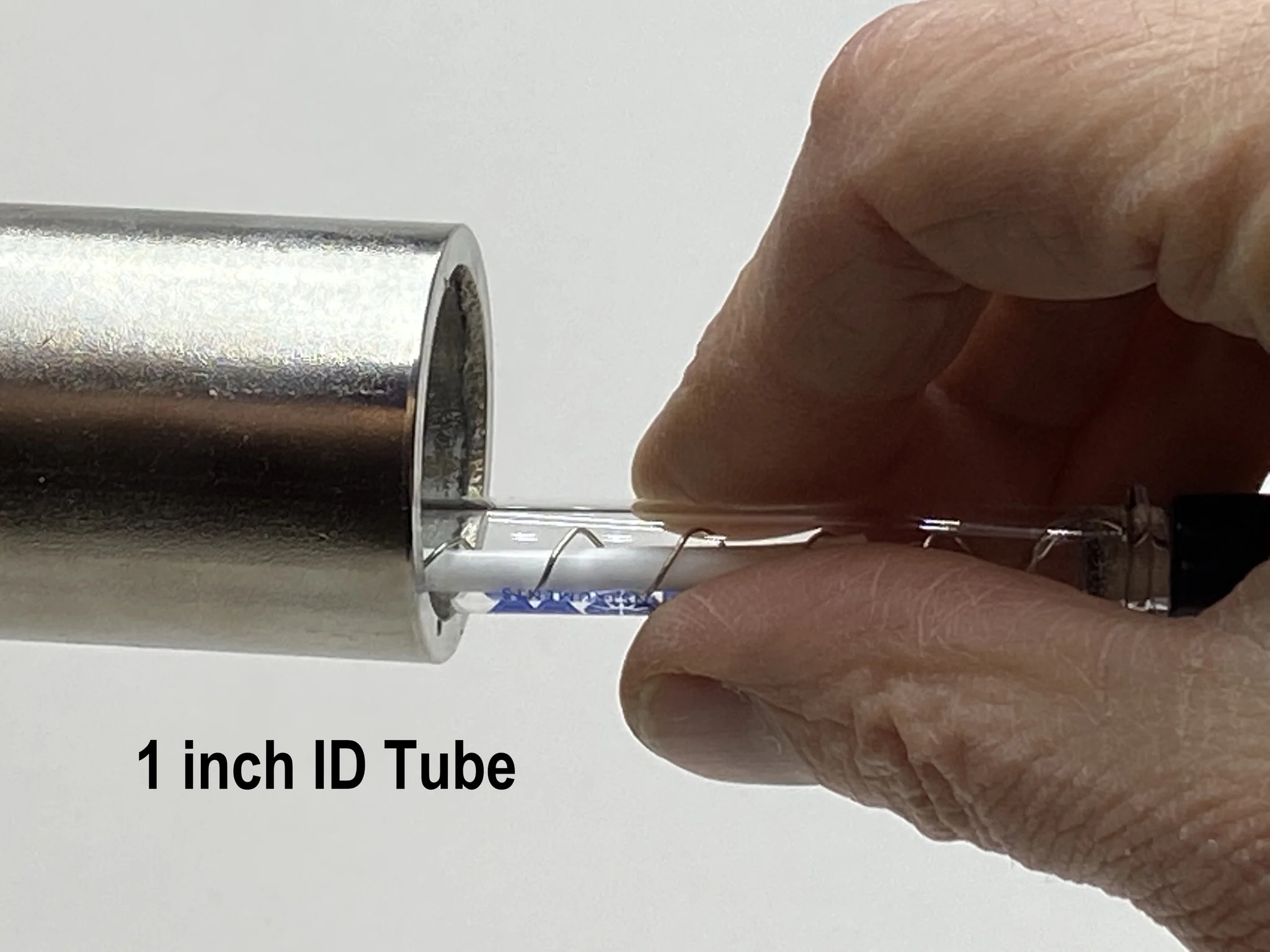

2. What is an Extruded Finned Tube?

An extruded finned tube is produced by mechanically extruding aluminum or copper fins over the tube surface, creating a continuous bond without welding.

Advantages:

- Outstanding corrosion resistance, ideal for Marine & Offshore Finned Tube Applications

- Superior long-term durability and fin adhesion

- Reduced fouling risk due to smooth surface

Limitations:

- Higher initial cost

- Limited to specific fin materials

3. Spiral vs Extruded: Performance Comparison

| Feature | Spiral Finned Tube | Extruded Finned Tube |

|---|---|---|

| Heat Transfer | High | High |

| Corrosion Resistance | Moderate | Excellent |

| Cost | Lower | Higher |

| Temperature Resistance | Very High | High |

| Best Applications | Boilers, heaters | Offshore, seawater cooling |

4. How to Choose the Right Finned Tube

- For high-temperature, budget-conscious projects → choose spiral finned tubes

- For corrosive or marine conditions → select extruded finned tubes

- Always consider lifecycle costs, not just initial price

5. Learn More

DLSS supplies both spiral finned tube and extruded finned tube solutions with precision manufacturing and strict quality control.

Contact us today at info@dlsspipe.com or visit www.dlsspipeline.com for a custom heat exchanger finned tube quote.