Meta Description:

Explore the top 10 critical applications of stainless steel tubes in the oil & gas industry. Learn how DLSS tubes perform under high pressure, corrosion, and extreme conditions.

Introduction

The oil and gas industry operates under extreme conditions—high pressure, corrosive environments, and fluctuating temperatures. To ensure safety and durability, stainless steel tubes are essential components across upstream, midstream, and downstream operations.

This article highlights the 10 most common applications of stainless steel tubes in the oil & gas sector and explains how DLSS delivers tubing that meets international standards and harsh service requirements.

1. Heat Exchanger Tubes

- Use: Cooling and condensing hydrocarbons, steam recovery

- Requirements: High thermal conductivity, corrosion resistance, dimensional accuracy

- Recommended Grades: TP316L, TP321, TP347H, Duplex 2205

- Standard: ASTM A213, EN 10216-5 TC2

2. Instrumentation & Control Tubing

- Use: Signal transmission for pressure, temperature, and flow devices

- Requirements: Clean internal surfaces, consistent wall thickness, tight tolerances

- Recommended Grades: TP316/316L, 904L, Incoloy 825

- Standard: ASTM A269, EN 10305-1

3. Downhole Chemical Injection Lines

- Use: Delivering corrosion inhibitors or scale reducers into the wellbore

- Requirements: Extreme corrosion resistance, sour service compliance (H₂S)

- Recommended Grades: Alloy 625, 825, Super Duplex S32750

- Standard: NACE MR0175 / ISO 15156

4. Hydraulic Control Lines (Umbilicals)

- Use: Control subsea equipment such as BOPs and valves

- Requirements: Pressure integrity, seawater resistance

- Recommended Grades: TP316L BA/EP, Incoloy 825

- Packaging: Encapsulated coil tubing, seamless

5. Flowline & Pipeline Weld Overlay Tubes

- Use: Internal corrosion protection in carbon steel pipelines

- Requirements: Metallurgical bonding, chemical compatibility

- Material Examples: Alloy 625 cladding, 316L liners

- Method: CRA weld overlay or clad pipe solutions

6. Gas Lift Systems

- Use: Enhancing oil extraction by injecting gas downhole

- Requirements: High pressure tolerance, scaling and corrosion resistance

- Recommended Grades: TP316L, Duplex 2205, Incoloy 825

- Certification: 3.2 by TÜV, SGS or BV for critical projects

7. Boiler & Furnace Tubes (Downstream)

- Use: Steam production and process heating in refineries

- Requirements: Oxidation resistance at high temperatures

- Recommended Grades: TP347H, TP310S, Incoloy 800H

- Standard: ASTM A213, ASME SA213

8. Desalination & Produced Water Treatment Units

- Use: Treating seawater or formation water for reuse or disposal

- Requirements: Chloride pitting resistance, stress cracking resistance

- Recommended Grades: Duplex 2205, 2507, Alloy 254SMO

- Finish: Bright Annealed or Electropolished

9. Flare & Vent Gas Recovery Systems

- Use: Safely transporting flammable gas emissions

- Requirements: Fire resistance, corrosion resistance

- Recommended Grades: TP304H, TP321, Alloy 600

- Testing: Hydro, PMI, UT per project spec

10. Refinery Reactors & High-Pressure Systems

- Use: Catalytic cracking, hydrogen production, and other processes

- Requirements: High yield strength, thermal stability

- Recommended Grades: Incoloy 800H, 825, Alloy 625

- Inspection: MTC + third-party 3.2 certification

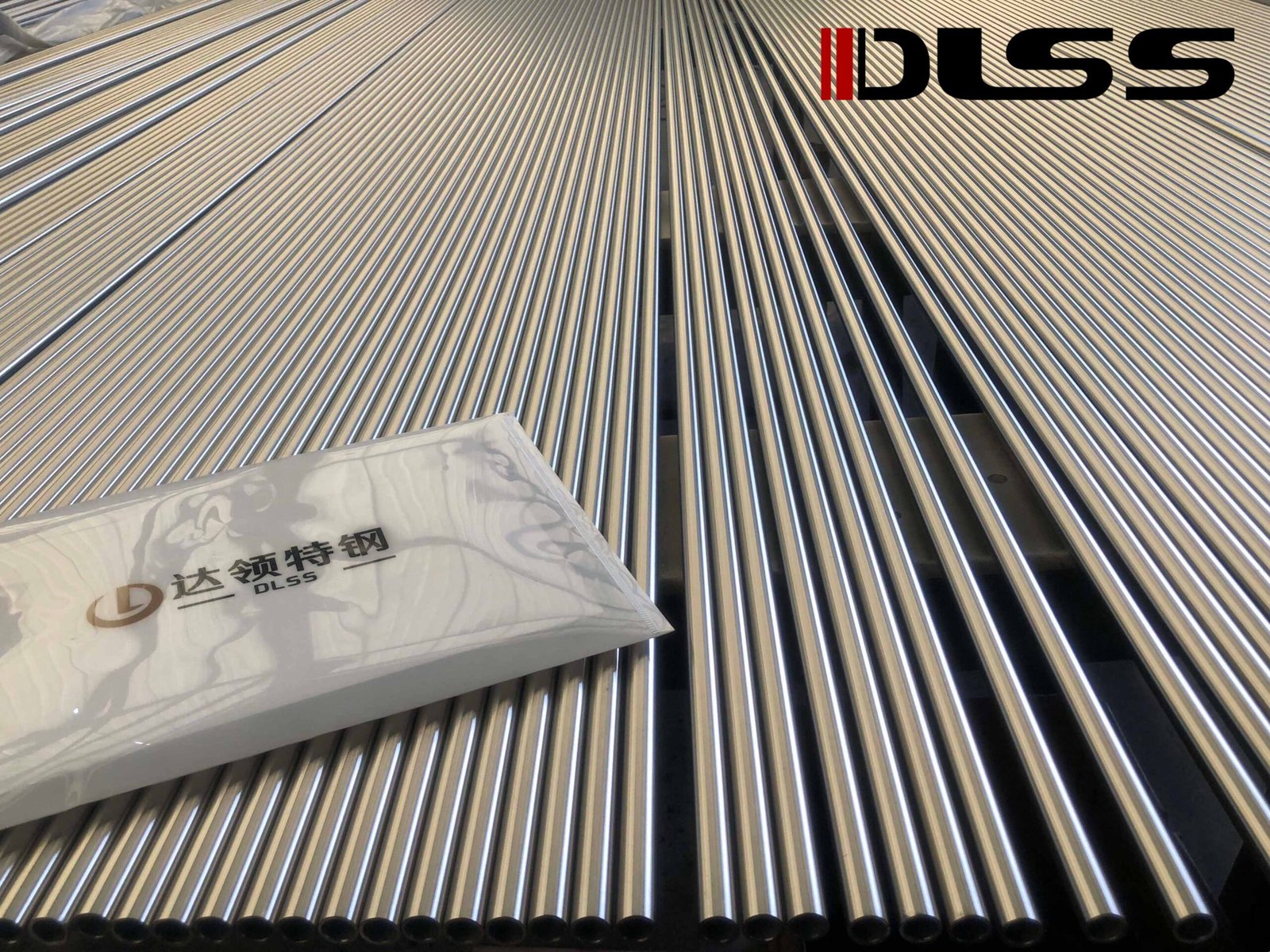

Why DLSS Stainless Steel Tubes Are Ideal for Oil & Gas

- ✔️ Full compliance with ASTM, EN, NACE, API standards

- ✔️ Available in BA, EP, pickled, and polished finishes

- ✔️ Hardness control (≤ 22 HRC for NACE)

- ✔️ Full documentation: EN 10204 3.1 / 3.2, PMI, UT, hydro

- ✔️ Strong experience with projects in Middle East, Turkey, Malaysia, Iran

Learn more from:

NACE MR0175 / ISO 15156

API – American Petroleum Institute

FAQs

Q1: Can DLSS tubes be used in offshore oil platforms?

Yes. DLSS supplies NACE-compliant, third-party certified tubing for offshore applications globally.

Q2: What is the max length for coiled umbilical tubes?

We can supply level wound coil (LWC) up to 1,500 meters in single coil depending on OD and material.

Q3: Can DLSS assist with tube material selection for sour service?

Yes. Our team evaluates project specs and recommends optimal alloy grades to resist SSC, HIC, and pitting.

Conclusion

The oil & gas industry demands tubing that withstands pressure, corrosion, and time. DLSS delivers reliable, certified, and custom-fabricated stainless steel tubes that serve every part of the oilfield—from seabed to refinery.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need stainless steel or alloy tubes for your oilfield project? DLSS offers custom solutions, fast turnaround, and international quality assurance.