Meta Description:

Explore the advantages of duplex stainless steel tubes. Learn about key grades like 2205 and 2507, their properties, and why they are preferred in harsh industrial environments.

Introduction

Duplex stainless steel tubes are rapidly becoming the preferred solution for demanding industries such as oil & gas, marine, chemical processing, and desalination. With their dual-phase structure—combining austenitic and ferritic phases—these materials offer a balance of strength, corrosion resistance, and cost-efficiency.

This article provides an in-depth look at duplex stainless steel tube grades, their key benefits, and their real-world industrial applications.

1. What Is Duplex Stainless Steel?

Duplex stainless steels have a mixed microstructure of approximately 50% ferrite and 50% austenite. This dual-phase structure gives them mechanical properties and corrosion resistance superior to standard austenitic stainless steels like 304 or 316.

2. Common Duplex Tube Grades and Standards

| Grade Name | UNS Number | EN Number | Common Standard |

|---|---|---|---|

| 2205 | S32205 | 1.4462 | ASTM A789 / EN 10216-5 |

| 2507 (Super) | S32750 | 1.4410 | ASTM A789 / EN 10216-5 |

| Lean Duplex | S32101 | 1.4162 | ASTM A789 / EN 10216-5 |

| 2304 | S32304 | 1.4362 | ASTM A789 |

DLSS manufactures seamless duplex and super duplex tubes with full EN 10204 3.1/3.2 certification.

3. Key Benefits of Duplex Stainless Steel Tubes

3.1. Superior Strength

- Yield strength is roughly twice that of 304/316 stainless steel

- Enables thinner walls, saving weight and cost

3.2. Excellent Corrosion Resistance

- Resists chloride stress corrosion cracking (SCC)

- Ideal for seawater, brine, and chemical exposure

3.3. Cost Efficiency

- Lower nickel and molybdenum content than 316L/904L

- Long service life with reduced maintenance

3.4. Weldability & Toughness

- Good weldability (but requires proper heat control)

- Performs well in cryogenic and high-pressure environments

4. Typical Applications of Duplex Tubes

| Industry | Application | Preferred Grade |

|---|---|---|

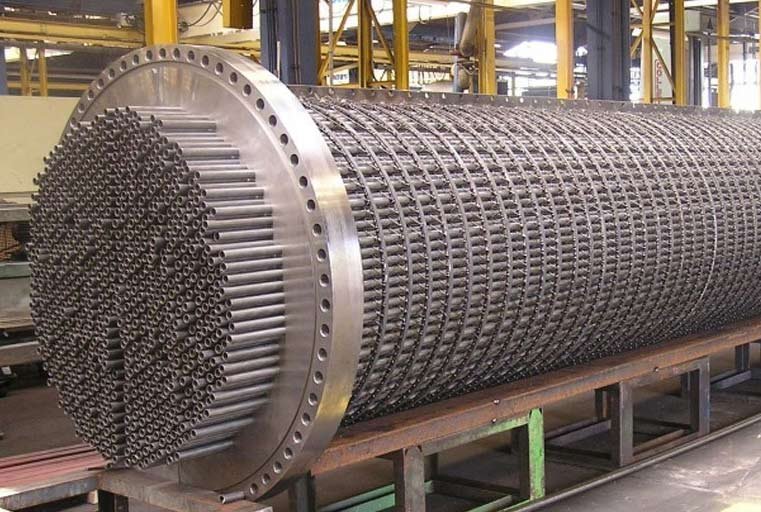

| Oil & Gas Offshore | Heat exchangers, control lines, piping | 2205, 2507 |

| Desalination Plants | Brine lines, evaporator tubes | 2507 |

| Marine Industry | Ballast systems, fire-fighting water lines | 2205, 2304 |

| Chemical Processing | Pressure vessels, reactors | 2205, S32101 |

| Pulp & Paper | Digesters, bleach plants | 2205 |

| Construction | Structural tubing in corrosive environments | Lean Duplex (S32101) |

5. Duplex vs Austenitic Stainless Steel (304/316)

| Property | Duplex (2205) | Austenitic (316L) |

|---|---|---|

| Yield Strength (MPa) | ~450 | ~200 |

| Pitting Resistance (PREN) | 35–40 | 25–28 |

| Chloride SCC Resistance | High | Moderate |

| Nickel Content | ~5–7% | ~10–14% |

| Cost | Comparable or lower | Higher (nickel-driven) |

For detailed reference:

Outokumpu Duplex Handbook (PDF)

6. DLSS Duplex Tube Capabilities

- Seamless and welded options

- Size range: 6 mm – 89 mm OD

- Wall thickness: 0.5 mm – 6.0 mm

- Surface finishes: Pickled, BA, EP

- NDT available: UT, ET, Hydro, PMI

- Certifications: ASTM A789 / A790, EN 10216-5, NACE MR0175

DLSS ensures tight dimensional tolerance and full traceability for duplex grades, suitable for critical international projects.

FAQs

Q1: Can duplex tubes replace 316L in most applications?

Yes, especially where strength and corrosion resistance are critical. However, consult a materials engineer for compatibility.

Q2: Are duplex tubes more difficult to weld?

They require careful control of heat input and cooling rate. DLSS provides welding support data upon request.

Q3: Is 2507 overkill for most applications?

2507 (super duplex) is ideal for extremely aggressive environments. For moderate chloride exposure, 2205 may be more cost-effective.

Q4: How do I request Ra or corrosion test data?

DLSS provides Ra reports, pitting resistance results, and full mechanical/chemical test data as part of every order.

Conclusion

Duplex stainless steel tubes offer a high-performance, cost-effective solution for industries facing high pressure, chloride corrosion, and weight constraints. DLSS supplies certified duplex and super duplex tubes tailored to your application’s demands.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Looking for duplex tube solutions for marine, chemical, or oil & gas projects? Contact DLSS for expert support and high-precision manufacturing.