Meta Description:

Learn the key differences between EN 10204 3.1 and 3.2 material certificates for stainless steel tubes. Understand which certificate your project needs and how DLSS ensures compliance.

Introduction

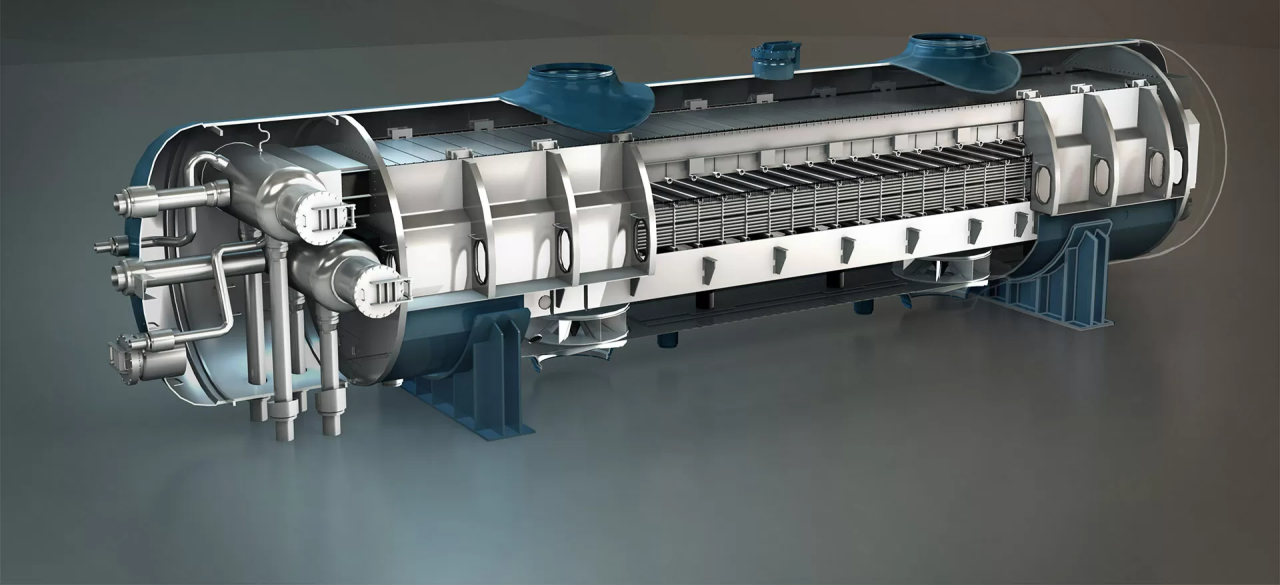

Material certification is essential for traceability and quality assurance in the supply of stainless steel tubes, especially in industries like oil & gas, power generation, and chemical processing.

The European standard EN 10204 defines different types of inspection documents. Among them, 3.1 and 3.2 certificates are the most commonly requested by engineers, EPC contractors, and quality inspectors.

In this article, we explain what these certificates are, how they differ, and when each is required.

What Is EN 10204?

EN 10204 is a standard issued by the European Committee for Standardization (CEN) that specifies the content and type of inspection documents issued by metal manufacturers.

It applies to all metallic products including:

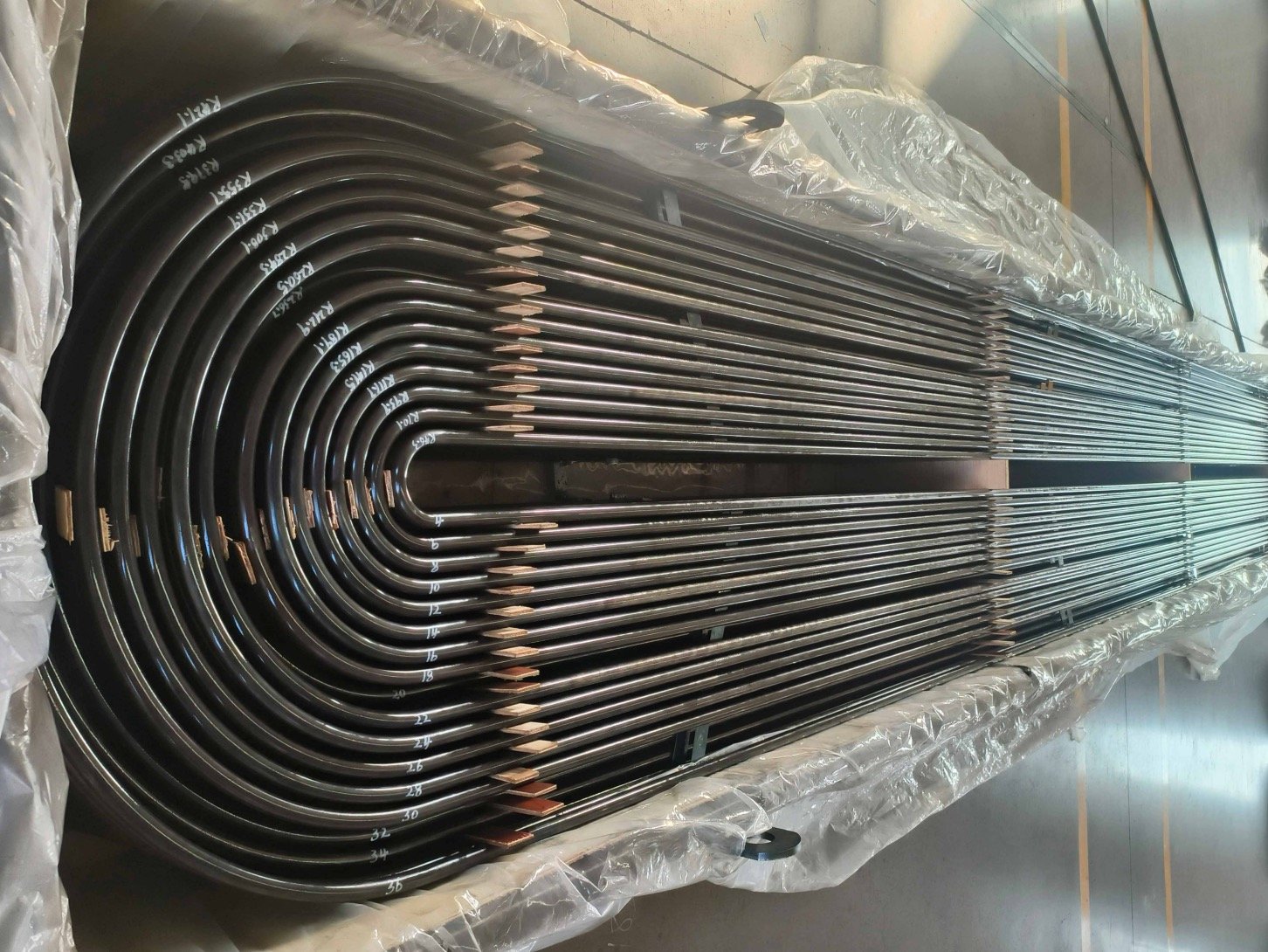

- Seamless stainless steel tubes

- Welded tubes

- Flanges, pipe fittings, and pressure parts

Definition of 3.1 Certificate

EN 10204 3.1 Certificate is issued by the manufacturer’s quality department, confirming that the supplied material:

- Complies with the purchase order and applicable standards

- Has passed all required mechanical and chemical tests

- Is traceable to specific heat numbers and batches

Signed by: Manufacturer’s authorized QA/QC representative

Content includes:

- Heat number

- Material grade and standard

- Chemical composition

- Mechanical properties

- Dimensional inspection results

- NDT or pressure test data (if applicable)

Typical Use: Accepted for most industrial projects and internal quality systems.

Definition of 3.2 Certificate

EN 10204 3.2 Certificate goes one step further. It is validated by an independent third-party inspection agency or the purchaser’s appointed inspector, in addition to the manufacturer.

Signed by: Manufacturer + Third-party inspector (e.g., SGS, TUV, BV, Lloyd’s)

Key Difference: 3.2 involves witness inspection of production or testing.

When required:

- High-risk projects (e.g., nuclear, pressure vessel, refinery piping)

- When specified in the purchase order

- Government or EPC-mandated projects

3.1 vs 3.2 Summary Table

| Feature | 3.1 Certificate | 3.2 Certificate |

|---|---|---|

| Issued by | Manufacturer | Manufacturer + Third Party |

| Witnessed by External Body | No | Yes |

| Traceable to Heat/Batches | Yes | Yes |

| Mechanical & Chemical Tests | Included | Included + Witnessed |

| Cost | Lower | Higher (due to inspector involvement) |

| Typical Projects | General industrial | Critical, high-spec projects |

How DLSS Supports Certified Supply

DLSS can supply both 3.1 and 3.2 certified stainless steel tubes according to:

- ASTM A213 / A312 / A269 / A789 / B111

- EN 10216-5

- NACE MR0175 / ISO 15156

- ASME Section II and III requirements

Inspection Partners:

DLSS works with leading third-party agencies including SGS, BV, TUV, Lloyd’s Register, and DNV to provide witnessed inspections and 3.2 endorsement.

Procurement Tip

When placing an order:

- Always specify in the PO if 3.2 certification is required

- Include the name of the authorized inspection agency (if applicable)

- Arrange inspection dates in advance to avoid delivery delays

- Ask for sample certificates if first-time supplier

SEO Keywords

EN 10204 3.1 certificate stainless pipe, EN 10204 3.2 tube certification, 3.1 vs 3.2 material cert, third-party witnessed inspection tube, TP316L 3.1 certified tube, heat number traceability stainless steel, DLSS 3.2 certificate pipe, stainless tube inspection requirement, BV TUV certified tube manufacturer, ASTM A213 with EN10204 certificate

Conclusion

For most applications, EN 10204 3.1 is sufficient. But for critical applications—especially those involving pressure, corrosive media, or regulated industries—a 3.2 certificate is required for added assurance.

DLSS supplies stainless steel tubes with full documentation, traceability, and inspection options tailored to your project’s compliance requirements.

Contact DLSS for Certified Tube Supply

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Our team will guide you through the material certification process and provide all necessary documents to support your technical and regulatory needs.