1. Introduction

Welding and fabrication are critical stages in the production and installation of titanium tubes and nickel alloy pipes. Both materials offer superior corrosion resistance and mechanical properties, but they require specialized welding techniques, strict process control, and skilled workmanship to ensure reliability in demanding applications such as desalination plants, LNG terminals, and chemical processing facilities.

2. Weldability of Titanium Tubes

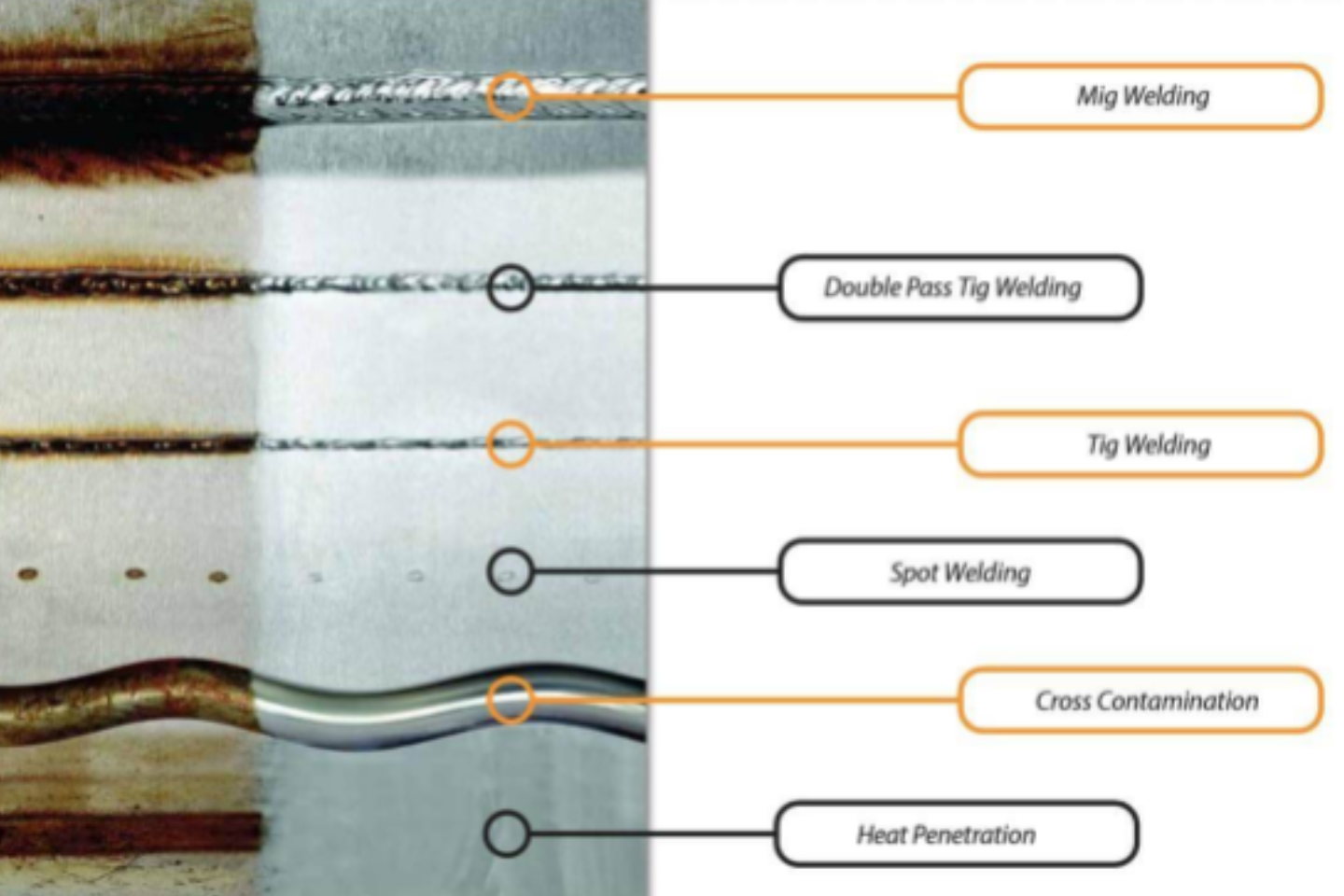

- Challenges:

- Titanium is highly reactive with oxygen, nitrogen, and hydrogen at elevated temperatures.

- Poor shielding leads to embrittlement and weld defects.

- Best Practices:

- Use of argon or helium inert gas shielding during GTAW (Gas Tungsten Arc Welding).

- Application of trailing shields and chamber welding for complete protection.

- Strict surface cleaning to remove oil, grease, and oxides.

- Standards:

- AWS D10.6 – Recommended Practices for Welding Titanium.

- ASTM B338 compliance requires weld integrity tests.

3. Weldability of Nickel Alloy Pipes

- Challenges:

- High nickel content increases thermal expansion, leading to distortion and cracking risks.

- Susceptibility to hot cracking in alloys such as Inconel 625 or Hastelloy C-276.

- Best Practices:

- GTAW or GMAW with matching filler metals (e.g., ERNiCrMo-3 for Alloy 625).

- Preheat generally not required, but controlled heat input is essential.

- Use low interpass temperature and multiple passes for thick-wall pipes.

- Standards:

- ASME Section IX – Welding qualifications for nickel alloys.

- NACE MR0175 for sour service piping systems.

4. Fabrication Considerations

- Titanium Tubes:

- Requires dedicated tools to prevent cross-contamination with steel.

- Cold forming is possible due to good ductility, but springback must be accounted for.

- Nickel Alloy Pipes:

- Work hardening occurs quickly, requiring careful machining with carbide tools.

- Stress-relief heat treatment may be required for some alloys.

5. DLSS Expertise in Welding & Fabrication

At DLSS, we deliver fabrication-ready titanium and nickel alloy tubes with:

- Strict welding procedure specifications (WPS) for titanium and nickel alloys.

- Certified welders qualified to ASME Section IX.

- Ultrasonic Testing (UT), Radiographic Testing (RT), and Dye Penetrant Testing (PT) for weld quality.

- Fabricated products including U-bend tubes, tube sheets, and spool assemblies.

- Full documentation package with ASTM, ASME, and EN standards compliance.

6. Conclusion & Call to Action

The weldability and fabrication of titanium and nickel alloy tubes require advanced expertise and precision. When performed correctly, these materials deliver unmatched durability in aggressive environments such as seawater cooling, LNG pipelines, and acid processing plants.

For EPC contractors and OEMs seeking fabricated titanium or nickel alloy piping systems, DLSS provides certified solutions with guaranteed quality.

Contact us to discuss your fabrication needs.

info@dlsspipe.com | www.dlsspipeline.com