Meta Description:

From oil refineries to desalination plants, stainless steel heat exchanger tubes are everywhere. Discover 10 major industries that rely on these tubes and why material selection matters.

Introduction

Stainless steel heat exchanger tubes are vital components in thermal systems that manage fluid and gas temperatures. Known for their corrosion resistance, strength, and versatility, these tubes operate under high pressure and temperature conditions in a wide variety of industries.

Whether you’re an engineer, project planner, or procurement officer, understanding where and why these tubes are used will help you specify the right materials and standards for your project.

1. Oil & Gas Industry

Heat exchangers are used throughout upstream, midstream, and downstream operations—for example, in crude oil heaters, gas processing units, and offshore platforms.

Stainless steel tubes like TP316L and Duplex S32205 are commonly selected for their resistance to chloride-induced pitting and crevice corrosion.

Many EPC projects also require EN 10204 3.2 certification, often with third-party inspection by SGS or TUV.

2. Power Generation

In thermal, nuclear, and combined cycle power plants, stainless steel tubes are essential in:

- Steam condensers

- Boiler economizers

- Superheaters and reheaters

Materials such as TP321 or TP347H are used for their high creep strength and stability under cyclic temperatures. Learn more from Energy.gov’s guide to power generation.

3. Chemical Processing

Corrosive fluids and extreme temperatures define the chemical and petrochemical sector, which depends on corrosion-resistant alloys in heat exchanger tubes.

Nickel alloys like Incoloy 825 and Hastelloy C276, listed by Special Metals and Haynes International, are selected for acid-resistant services.

4. Marine and Shipbuilding

In seawater cooling systems, Admiralty Brass C44300 and CuNi 90/10 (C70600) tubes offer excellent biofouling and erosion resistance.

Visit Naval Sea Systems Command for specifications on marine condenser design, where these tubes are often specified.

5. Food & Beverage Processing

Hygienic heat exchangers in milk pasteurizers, juice heaters, and brewing tanks require materials with smooth, crevice-free surfaces.

Bright annealed stainless steel tubes, compliant with 3-A Sanitary Standards, are widely used in these applications.

Grades like TP304 and TP316L, often polished to Ra ≤ 0.5 μm, are ideal for clean-in-place (CIP) systems.

6. Pharmaceutical and Biotech

In sterile environments, heat exchangers ensure temperature control in WFI (Water for Injection) systems, reactors, and lyophilizers.

Pharmaceutical plants often specify:

- ASTM A269 TP316L tubes

- ASME BPE-compliant polished tubes

See ISPE’s guidance for regulatory design expectations in cleanroom heat exchange systems.

7. HVAC and District Cooling

Chillers, absorption coolers, and central AC units in skyscrapers and airports use stainless steel tubes in:

- Evaporators

- Condensers

- Cooling towers

Many HVAC designers reference ASHRAE standards for system performance, especially where chloride-laden environments (e.g., coastal cities) require 316L or Duplex steel.

8. Automotive and Aerospace

Stainless tubes are used in:

- Turbo intercoolers

- Exhaust gas recirculation (EGR) coolers

- Aircraft environmental control systems

Lightweight, high-strength alloys like TP409, TP439, and TP347HFG are often used. Reference SAE International for aerospace thermal system specs.

9. Water Treatment and Desalination

In reverse osmosis plants, high pressure and seawater corrosion necessitate the use of:

- Duplex 2205 / 2507

- Super Austenitic Alloys like 254 SMO

These are essential in brine heaters, energy recovery units, and condenser loops. Read more on IDA’s desalination technology hub.

10. Renewable Energy & Hydrogen

In emerging hydrogen production, geothermal and CSP (concentrated solar power) applications, stainless tubes handle fluids with elevated temperatures, sulfur, or saline content.

Materials like Inconel 625, TP316Ti, and Duplex stainless offer long life under harsh conditions.

Conclusion

Stainless steel heat exchanger tubes are used across almost every modern industrial sector. While each industry has unique challenges, the right choice of tube material, surface finish, testing, and certification can dramatically affect system life, reliability, and total cost of ownership.

Whether you’re sourcing for seawater cooling, pharma steam systems, or refinery heat exchangers, understanding application-specific requirements is key.

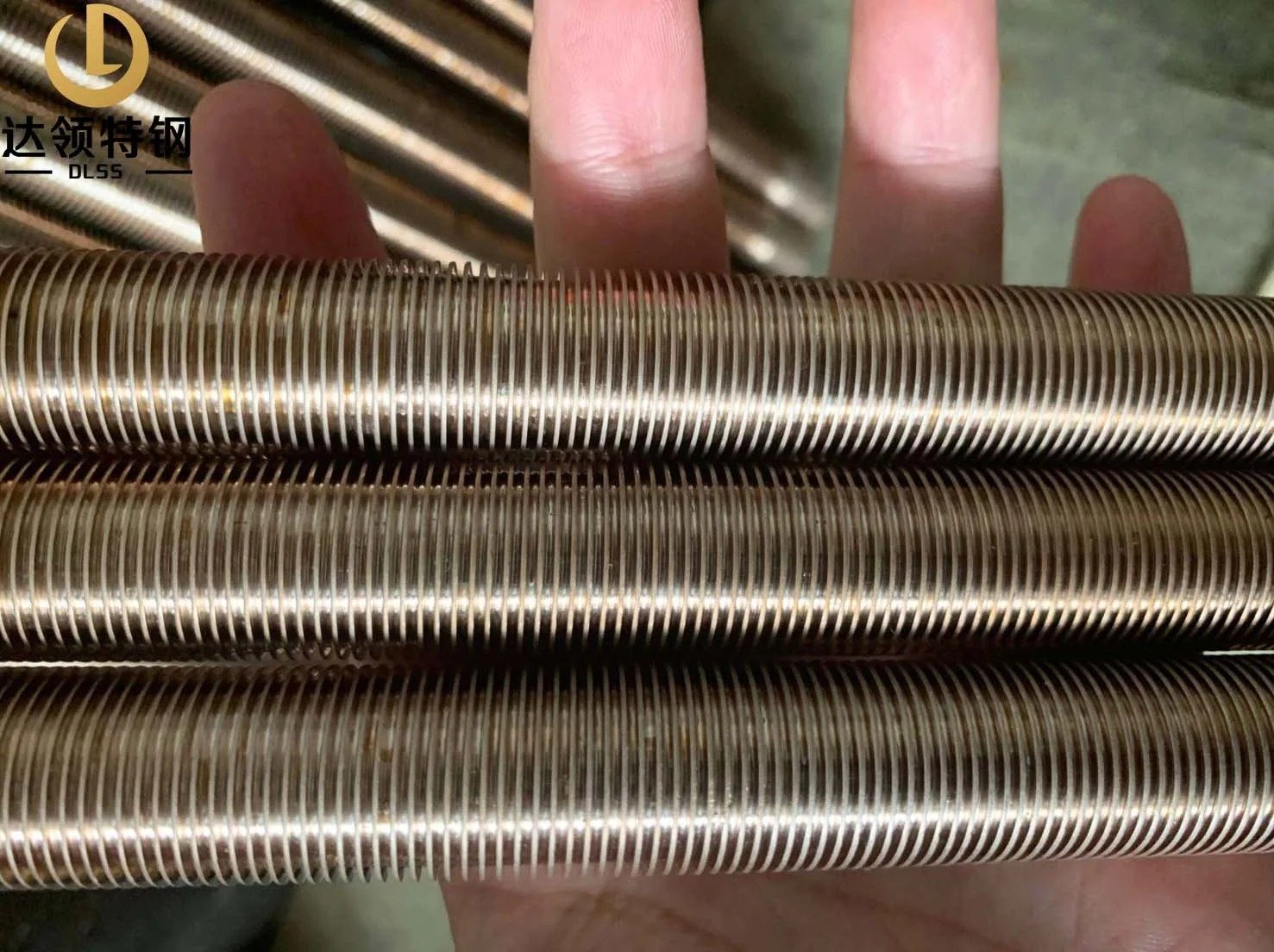

DLSS offers custom-manufactured seamless and welded stainless steel tubes, full testing and certifications, and export-ready packaging to over 40 countries.

Contact Us

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let DLSS help you choose the right stainless steel tube for your industry—with confidence, compliance, and complete documentation.