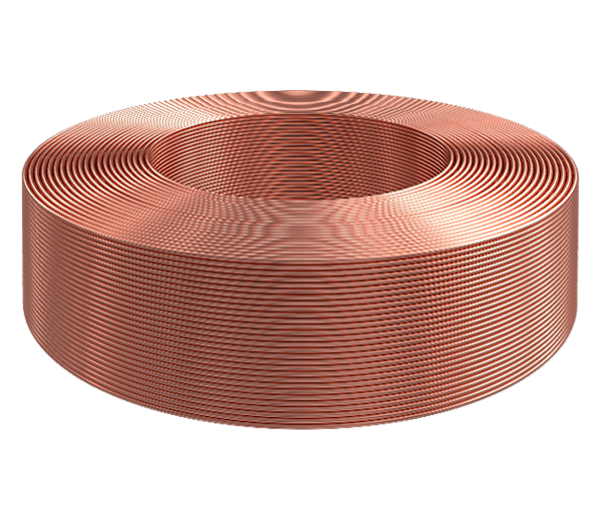

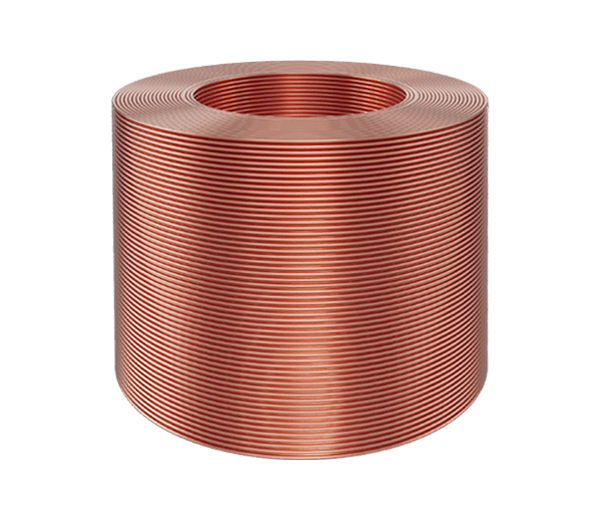

What Are Inner Grooved Coil Tubes?

Inner grooved coil tubes, also known as ribbed tubes or micro-fin tubes, are seamless or welded coil tubes with precisely formed helical grooves on the internal surface. These grooves increase turbulence in fluid flow, thereby enhancing the heat transfer coefficient.

They are widely used in:

- Air conditioning systems (A/C)

- Chillers and refrigeration units

- Condensers and evaporators

- Heat pump water heaters

- Compact heat exchangers for automotive and commercial HVAC

Why Choose Inner Grooved Tubes?

30–50% better heat transfer than smooth tubes

Enhanced energy efficiency for refrigeration units

Reduced refrigerant charge due to improved evaporation

Better oil return in vertical systems

Compact system design thanks to superior performance

Micro-fin tubes are a must for systems using eco-friendly refrigerants like R32, R410A, CO₂, or R290.

Key Design Features

| Parameter | Typical Range |

|---|---|

| Tube Outer Diameter | 5 mm – 16 mm |

| Groove Depth | 0.05 mm – 0.3 mm |

| Number of Grooves | 50 – 70 grooves |

| Groove Angle | 18° – 24° |

| Coil Diameter | As per client’s requirement |

| Tube Wall Thickness | 0.25 mm – 1.2 mm |

| Post-Grooving WT | e.g., 0.81 mm for 19.05 mm OD tubes |

DLSS Materials & Standards

| Base Material | Standard | Application Notes |

|---|---|---|

| Copper (C12200) | ASTM B280 | Common in HVAC systems |

| Stainless Steel TP304L | ASTM A213 | High strength, corrosion resistance |

| Stainless Steel TP316L | ASTM A213 | For aggressive/corrosive environments |

| Titanium Grade 2 | ASTM B338 | For seawater chillers and special use |

| Duplex S32205 | ASTM A789 | High strength + corrosion resistance |

Inner Groove Tube Manufacturing Process

- Tube forming (welding or extrusion)

- Cold drawing to reach precise OD & WT

- Internal grooving via mechanical mandrel or spinning head

- Annealing (for copper or SS tubes as required)

- Bending into coils (as per project specs)

- Pressure testing & surface inspection

Performance vs. Smooth Tubes

| Parameter | Smooth Coil Tube | Inner Grooved Tube |

|---|---|---|

| Heat transfer | Standard | 30–50% higher |

| Refrigerant efficiency | Normal | More effective evaporation |

| Oil return | Moderate | Faster, especially vertical |

| System size | Larger | Smaller & compact |

DLSS Quality Control

- Dimensional check (OD, WT, Groove depth)

- Non-destructive testing (Eddy current, hydro)

- Hardness and tensile test

- Internal surface visual inspection

- Coil forming inspection

- Surface finish: pickled, bright annealed, or customized

Applications by Industry

| Industry | Application Use Case |

|---|---|

| HVAC | Refrigerant piping, chillers, A/C units |

| Home appliances | Heat pump water heaters |

| Automotive | Compact refrigerant heat exchangers |

| Food cold chain | CO₂-based chillers |

| Green buildings | R32 high-efficiency A/C systems |

Packaging

- Individually plastic capped

- Coil wrapping with PE film

- Steel-framed or fumigation-free wooden crates

- Third-party inspection & export documents available

DLSS Product Highlights

- Customized groove geometry per refrigerant type

- Coil length up to 50 meters

- Tube OD from 5mm to 25.4mm

- Low wall-thinning rate post-grooving

- Ideal for high-efficiency HVAC system builders

- inner grooved coil tube

- micro-fin copper tube

- stainless steel inner ribbed coil

- TP304L inner grooved tube for chiller

- HVAC coil tube manufacturer

- enhanced surface tubing

- R410A microfin tube

- spiral inner grooved stainless tube

- refrigerant coil tube

- high-efficiency evaporator tube

Contact DLSS for Custom IG Tube Solutions

Looking for high-performance inner grooved coil tubes tailored to your HVAC or refrigeration system?

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

We support technical drawing, third-party test certification, and global shipping.