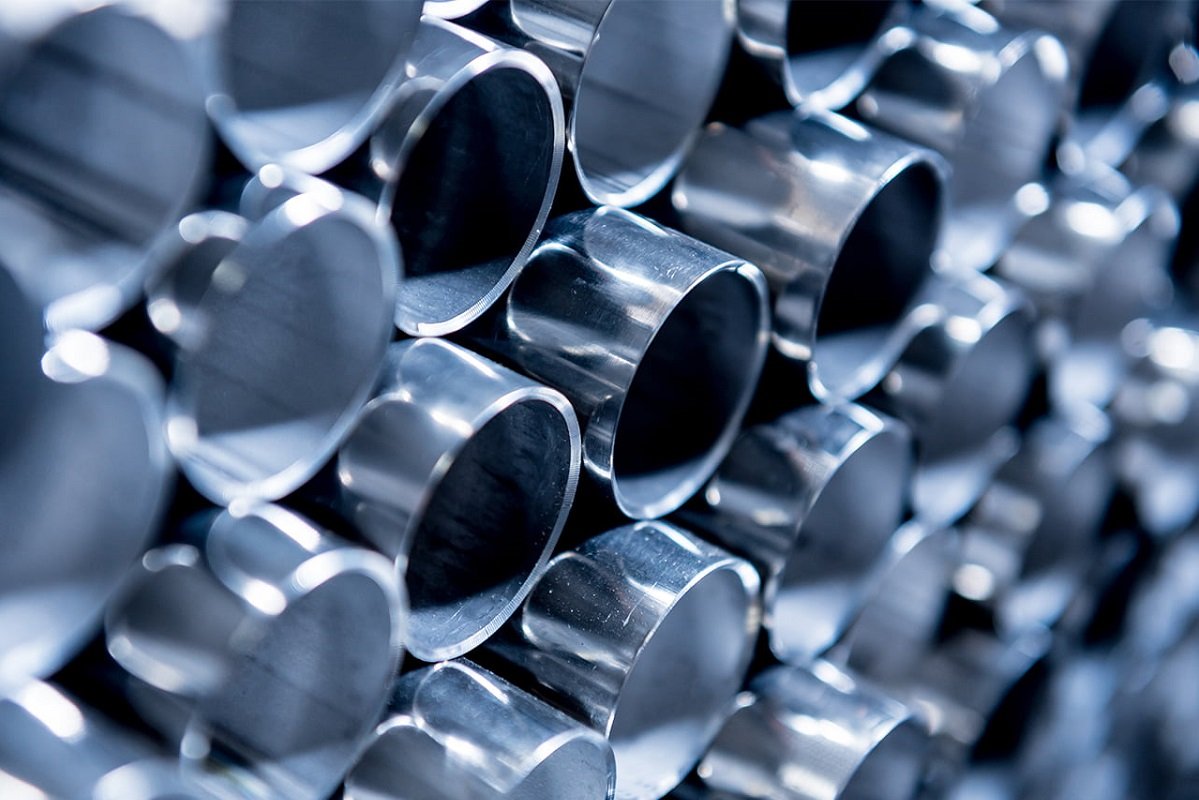

When designing a high-performance heat exchanger, tube material is a critical factor. Stainless steel, particularly in seamless form, is gaining popularity across industries thanks to its mechanical strength, corrosion resistance, and thermal reliability. In this article, we’ll break down why seamless stainless steel tubes are the ideal choice for demanding heat exchanger applications.

1. Uniform Wall Thickness for Stable Heat Transfer

Seamless tubes are manufactured without weld seams, resulting in:

- Uniform tube wall thickness

- Consistent thermal performance

- Fewer weak points in heat transfer

This is crucial in shell-and-tube heat exchangers where consistent flow and thermal balance are required.

2. High Pressure and Temperature Resistance

Compared to welded tubes, seamless stainless steel tubes have:

- Higher burst pressure tolerance

- Better resistance to creep and fatigue

- Minimal risk of deformation under thermal cycling

This makes them perfect for power plants, petrochemical refineries, and high-temperature systems.

3. Superior Corrosion Resistance

Grades like TP304, TP316L, and TP321 offer resistance to:

- Chlorides

- Acidic and alkaline media

- Oxidizing environments

This prevents tube wall thinning, pitting, and early failure—ensuring system longevity.

4. Low Maintenance and Longer Lifespan

Because of their strength and resistance to corrosion, seamless stainless tubes typically:

- Require less frequent maintenance

- Last longer in service

- Reduce system downtime and repair costs

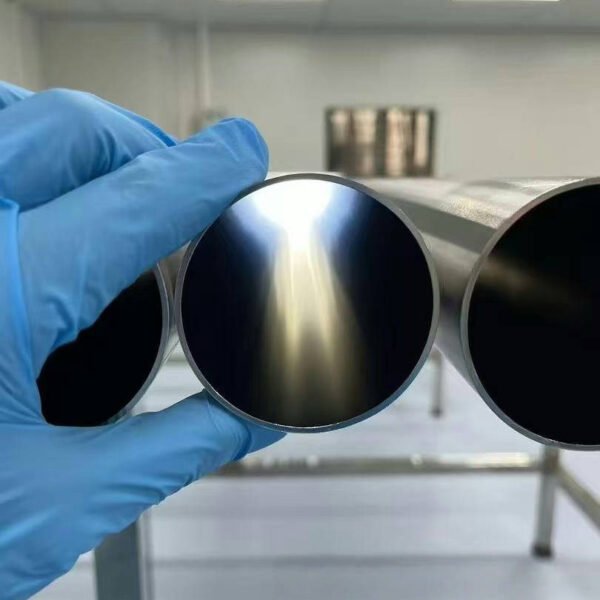

5. Clean Surface Finish = Better Flow Efficiency

At DLSS, we apply pickling and passivation to remove surface oxides and impurities, resulting in:

- Clean, smooth internal surfaces

- Improved fluid flow

- Less scaling and fouling

This directly contributes to better overall heat transfer efficiency.

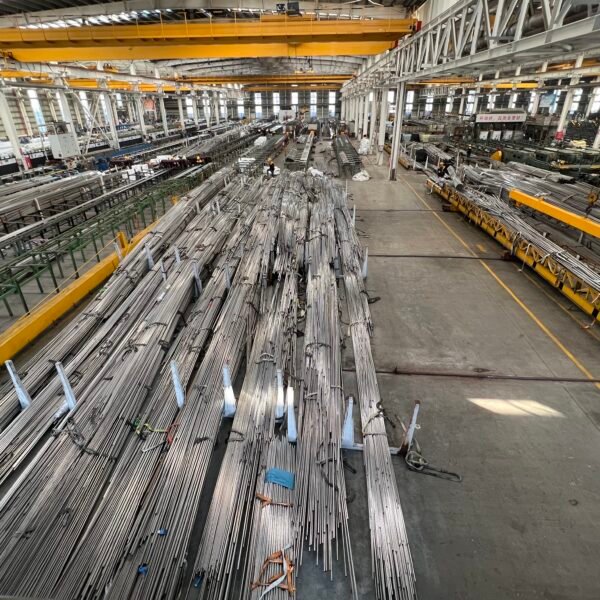

Final Thoughts

If your project demands reliability under pressure, aggressive media, or extreme heat, seamless stainless steel tubes are your best bet. DLSS provides high-precision tubes with industry-leading tolerances, surface finish, and quality assurance.

Looking for a dependable tube supplier?

Visit DLSS to explore our stainless steel solutions.