1. Introduction

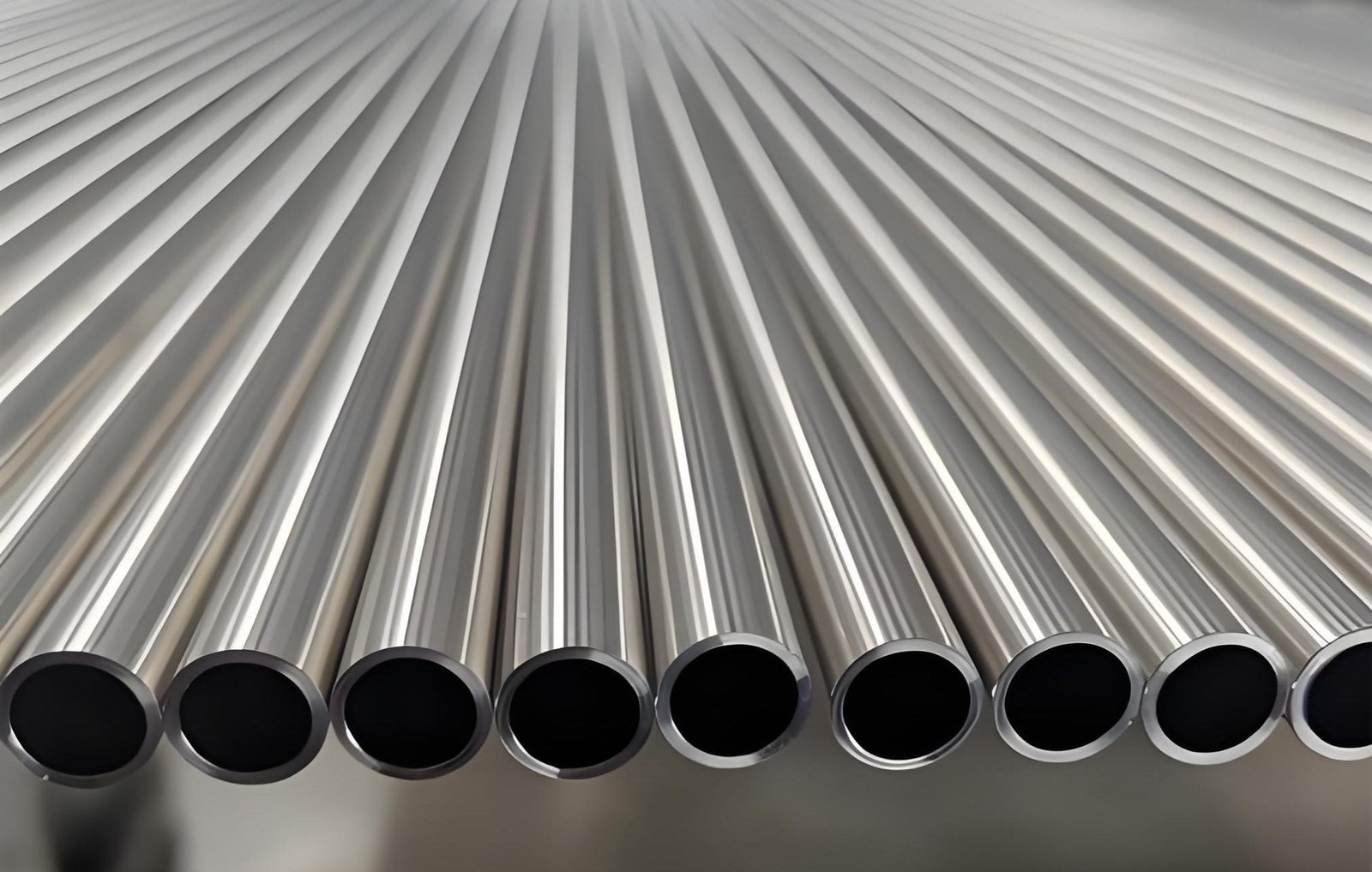

When sourcing nickel alloy and titanium pipes for chemical plants, desalination projects, or power plants, compliance with ASTM standards is a key requirement. ASTM (American Society for Testing and Materials) specifications define the chemical composition, mechanical properties, testing, and delivery conditions for these critical materials. This article provides a complete overview of the most important ASTM standards relevant to nickel-based alloy pipes and titanium tubes.

2. Key ASTM Standards for Nickel Alloy Pipes

ASTM B444 – Inconel 625 Seamless Pipe and Tube

- Covers seamless nickel-chromium-molybdenum-columbium alloy (Inconel 625).

- Applications: Offshore piping, flue gas desulfurization, chemical plants.

ASTM B423 – Incoloy 825 Seamless Pipe and Tube

- Nickel-iron-chromium alloy with molybdenum and copper.

- Applications: Sulfuric acid piping, chemical processing heat exchangers.

ASTM B622 – Hastelloy C-276 Seamless Pipe and Tube

- Nickel-molybdenum-chromium alloy with tungsten.

- Applications: Acid processing, reactors, scrubbers.

ASTM B619 / B626 – Welded Nickel Alloy Pipe and Tube

- Specifies welded pipe/tube manufacturing for various nickel alloys.

- Applications: Large-diameter piping systems in chemical and energy plants.

Reference: Nickel Alloys – ASTM Standards.

3. Key ASTM Standards for Titanium Pipes and Tubes

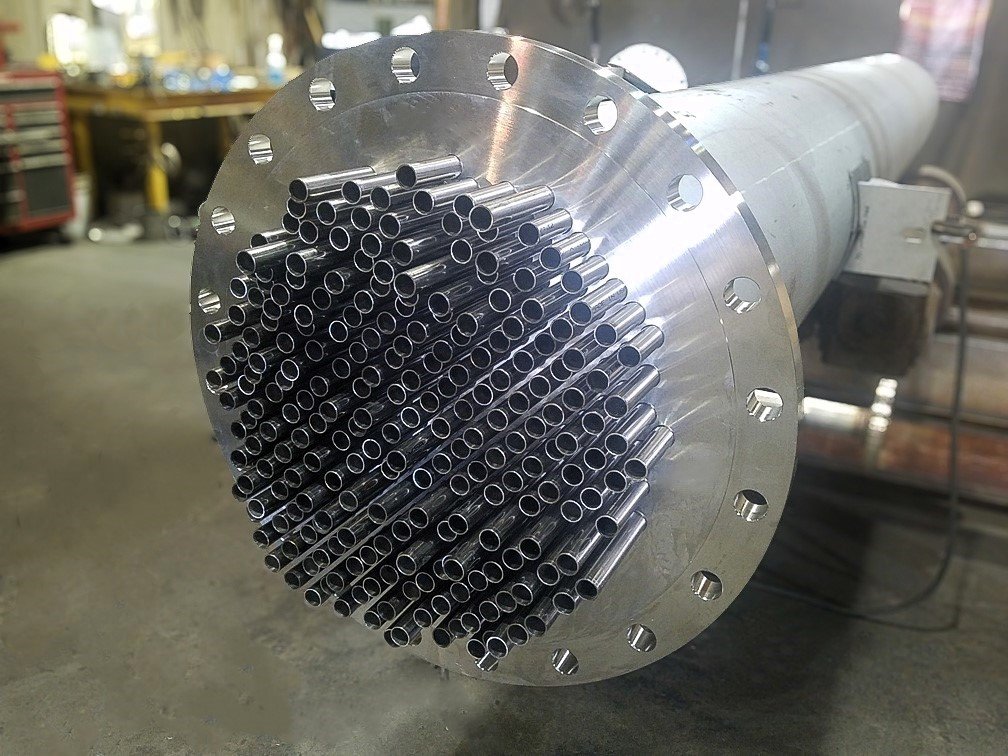

ASTM B338 – Seamless and Welded Titanium Tubes for Condensers and Heat Exchangers

- Covers Grades 1, 2, 7, 11, 12, 16, 17 titanium tubes.

- Widely used in seawater desalination plants and power plant condensers.

ASTM B861 – Seamless Titanium Pipe

- Covers seamless titanium and titanium alloy pipe for pressure service.

- Applications: Aerospace piping, chemical process industries.

ASTM B862 – Welded Titanium Pipe

- Specifies welded titanium pipes, often used for larger diameters.

ASTM B337 – Seamless Titanium Pipe

- Used for industrial and aerospace pressure systems.

Reference: ASTM B338 Titanium Tubes Standard.

4. Importance of ASTM Compliance in Projects

- EPC Contractors and End-Users: Require ASTM compliance for bid qualification.

- Third-Party Inspection: TÜV, DNV, LR often verify ASTM conformity through EN 10204 3.1/3.2 certificates.

- Project Risk Reduction: Non-compliant material risks rejection, delays, and penalties.

5. Nickel vs Titanium – Standard Selection in Practice

| Project Type | Recommended Standard (Nickel) | Recommended Standard (Titanium) |

|---|---|---|

| Offshore Oil & Gas | ASTM B444 (Inconel 625), B622 (C-276) | ASTM B861 |

| Chemical Processing | ASTM B423 (Incoloy 825), B622 (C-276) | ASTM B337 |

| Desalination & Power | ASTM B444 (625), B423 (825) | ASTM B338 (GR2/GR12) |

| Aerospace / High-Tech | ASTM B444 / B622 | ASTM B861 (Seamless) |

6. DLSS Expertise in ASTM-Compliant Pipes

At DLSS, we manufacture and export nickel alloy and titanium pipes fully compliant with ASTM standards, including:

- Nickel Alloy: ASTM B444, B423, B622, B619, B626.

- Titanium: ASTM B338, B861, B862, B337.

- Full EN 10204 3.1/3.2 certification available.

- Third-party inspection by TÜV, DNV, LR, ABS.

- Custom sizes, U-bend tubes, and project-specific delivery schedules.

7. Conclusion & Call to Action

ASTM standards are essential references for ensuring the quality and reliability of nickel alloy and titanium piping systems. Whether your project involves chemical plants, desalination units, or aerospace systems, DLSS delivers ASTM-compliant solutions with strict quality control.

Contact DLSS for ASTM-compliant nickel alloy and titanium pipes.

info@dlsspipe.com | www.dlsspipeline.com