1. Introduction

In the Japanese stainless steel tube market, buyers often compare ASTM (American Society for Testing and Materials) and JIS (Japanese Industrial Standards) specifications. Both systems have rigorous requirements, but understanding their differences is key to choosing the right stainless steel seamless tube Japan for specific applications such as 熱交換器 (heat exchangers) and 産業配管 (industrial piping).

2. Overview of ASTM and JIS Standards

ASTM A213 (for seamless austenitic stainless steel tubes):

- Common grades: TP304, TP316, TP321, etc.

- Covers tubes for boilers, superheaters, and heat exchangers

- Testing: hardness, flattening, flaring, hydrostatic or NDT

JIS G3459 (for seamless stainless steel pipes):

- Common grades: SUS304, SUS316, SUS321, etc.

- Focused on corrosion-resistant piping at elevated temperatures

- Testing: tensile, flattening, hydraulic pressure

Key Difference:

- Dimension tolerances: JIS often specifies tighter OD/WT tolerances for domestic applications in Japan

- Marking & documentation: JIS requires Japanese format and labeling for local use

3. When to Choose ASTM vs JIS in Japan

- For Export Projects:

ASTM is more recognized in international projects involving Japanese EPC contractors working overseas. - For Domestic Installations:

JIS is preferred for projects in Japan, especially in public infrastructure, marine, and food industry applications. - For Mixed Standard Requirements:

Some Japanese clients accept dual-certified tubes (ASTM + JIS) to maintain flexibility in sourcing and compliance.

Reference: JIS G3459 Standard | ASTM A213 Standard

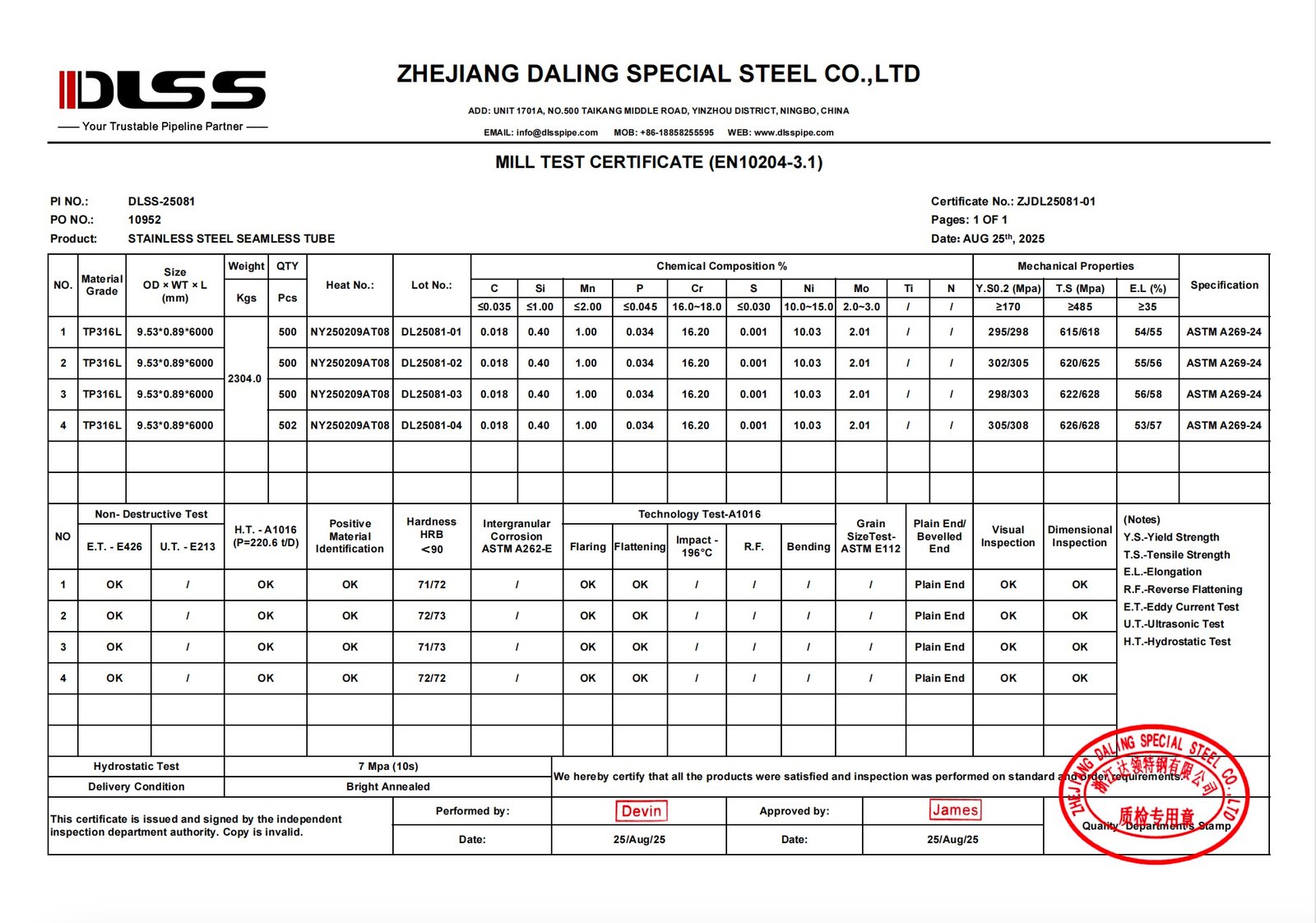

4. DLSS Dual Standard Supply Capability

DLSS manufactures and supplies dual-certified tubes meeting both ASTM and JIS requirements:

- Full chemical & mechanical testing for both standards

- Marking in both ASTM and JIS formats

- Certification packages in English & Japanese

- Strict surface quality control for 外観検査 (appearance inspection)

- Short lead times for urgent orders

5. Benefits for Japanese Buyers

- Avoids supply chain delays when switching between domestic and export projects

- Maintains compliance with Japanese regulation while satisfying global project requirements

- Offers better flexibility in inventory management for distributors and trading companies

6. Conclusion & Call to Action

Whether you need ASTM vs JIS stainless tube Japan, DLSS offers precise manufacturing, dual-standard compliance, and strong export packaging to meet your needs. Contact us to discuss your next project.

info@dlsspipe.com | www.dlsspipeline.com